Leakage detecting method of vacuum brake device

A vacuum brake and brake hose technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the problem of vacuum brake device damage, low efficiency, and poor effect and other issues, to achieve the effect of improving production efficiency, obvious effect, and low difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

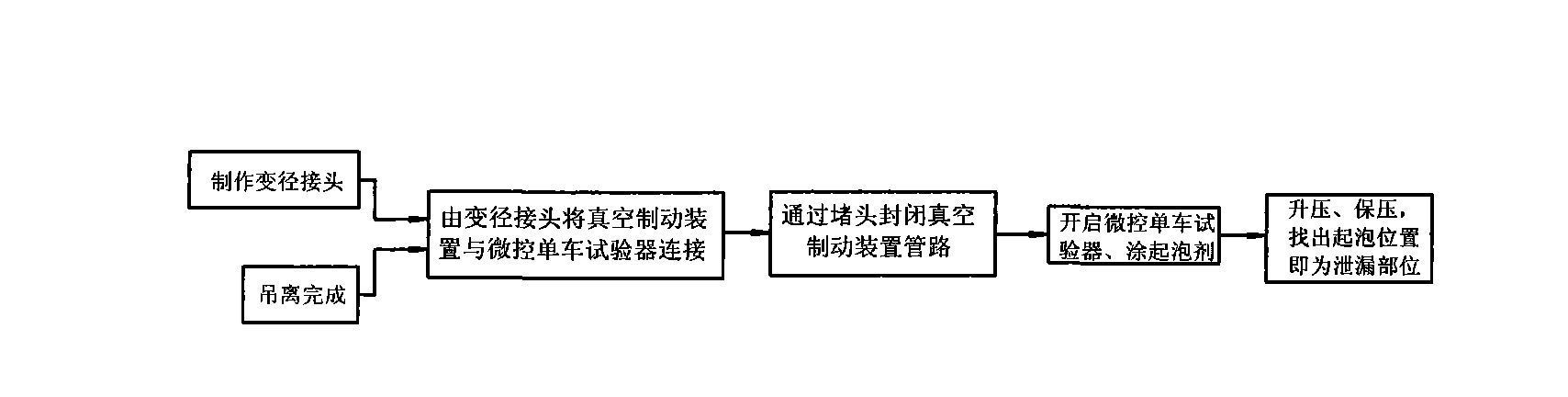

[0029] The leak detection method of the present invention is based on the idea of making a reducing joint and a plug, one end of the reducing diameter is connected to the end of the vacuum device, and the other end is connected to the micro-controlled bicycle tester (for air brake test), and the Close the brake line with a plug at the other end. Ventilation exerts positive pressure on the entire vacuum pipeline, smears soapy water at each joint, maintains pressure after ventilation, and the joint where the soap bubbles blow is the leakage part.

[0030] The concrete steps of the present invention are:

[0031] [1] Make a reducing joint, the joint has two ends of the interface, both ends of the interface are processed into internal threads, the internal thread of one end is M50, and the internal thread of the other end is M42;

[0032] [2] Make a plug, one end of the plug is solid, and the interface at the other end is processed into an internal thread, and the specification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com