Pipe joint assembly and hot-water boiler system using the same

A technology for joining components and pipes, applied in the direction of pipes/pipe joints/fittings, hose connection devices, water heaters, etc., can solve problems such as hot water leakage, boiler dumping, inconvenience, etc., to improve air tightness and reduce noise , the effect of improving the economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

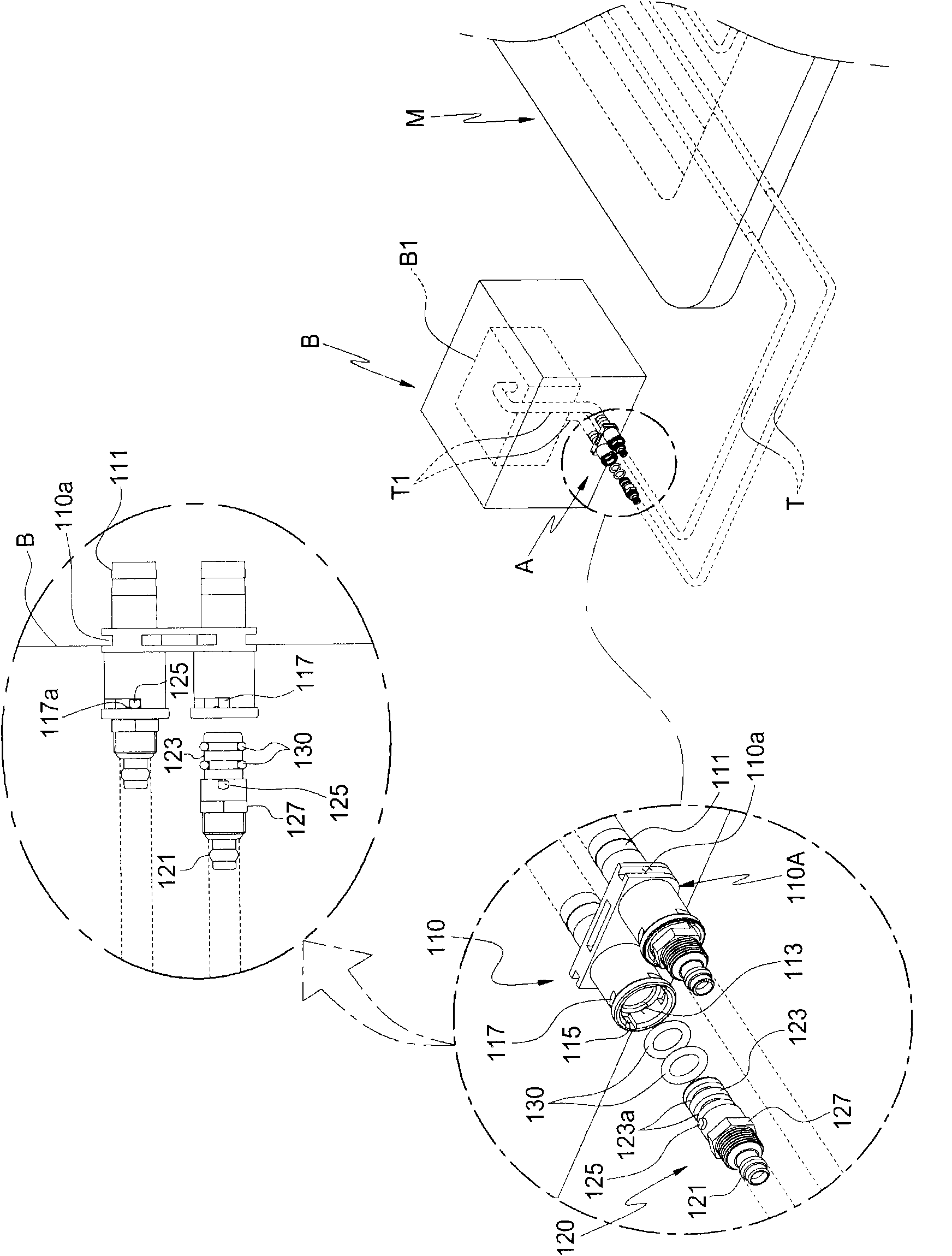

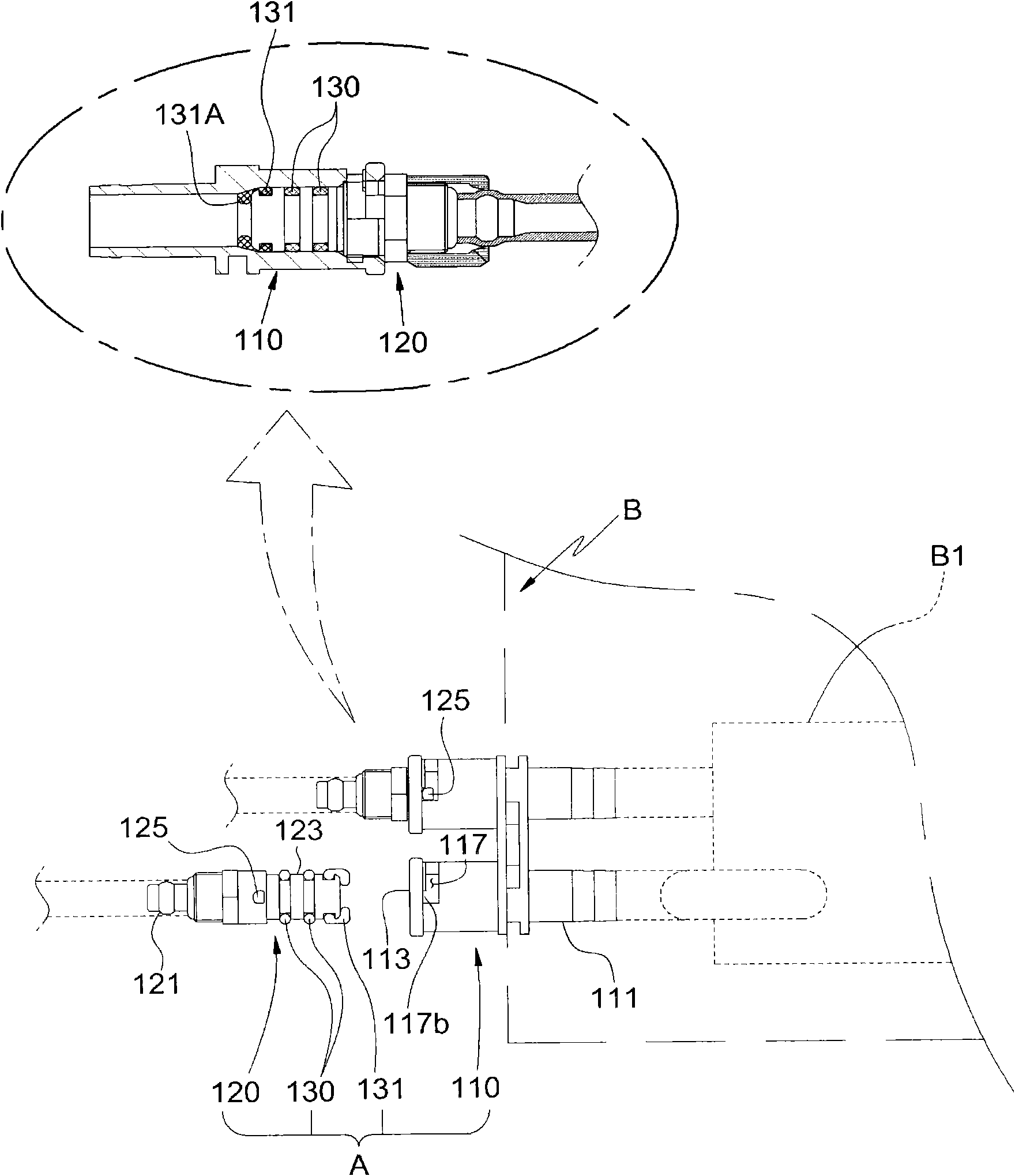

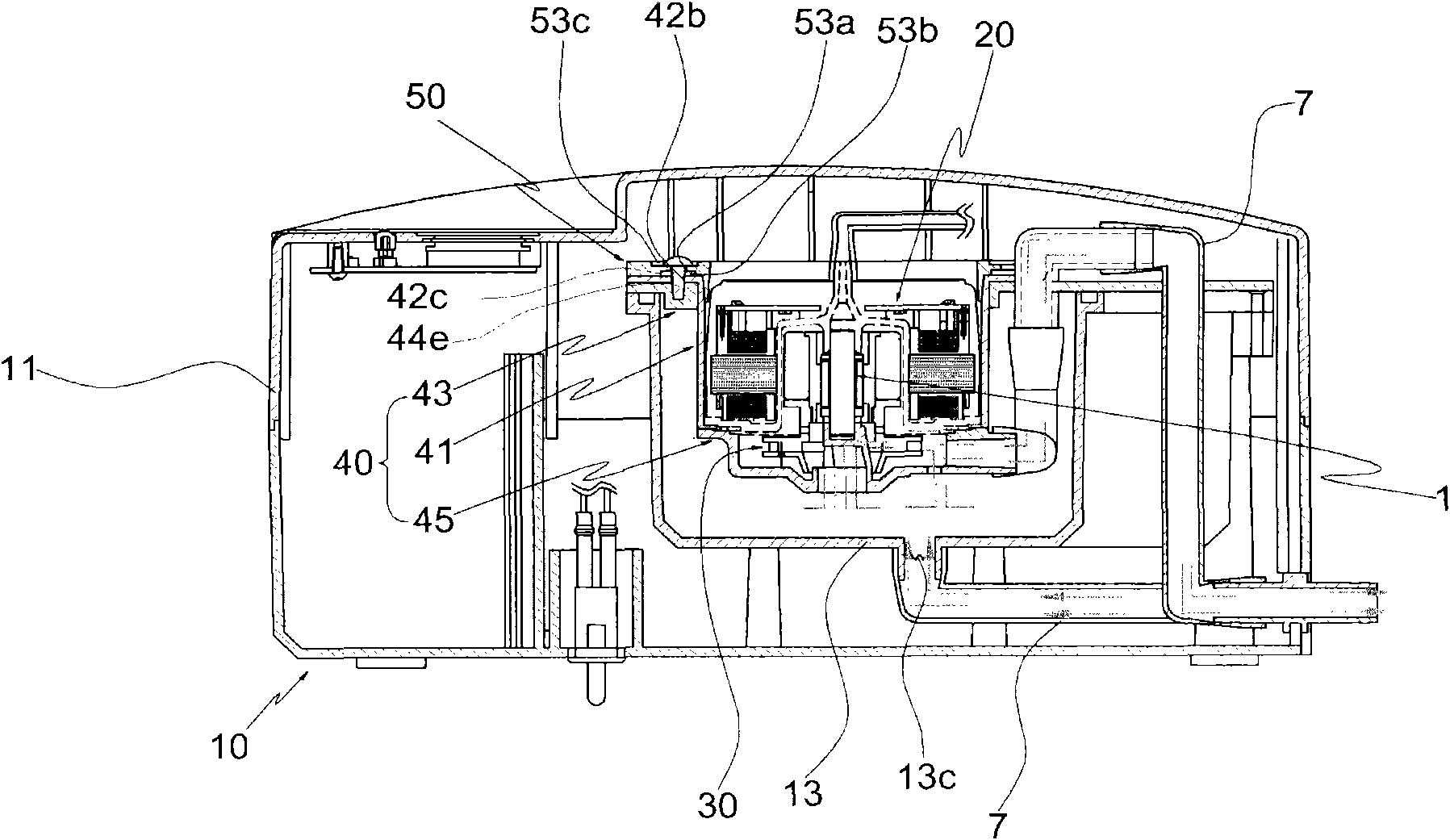

[0075] Below, the present invention will be described in detail in conjunction with the accompanying drawings.

[0076] The present invention is susceptible to various modifications and forms, and in the following, aspects (or embodiments) thereof will be described in detail. However, this does not limit the specific form of the present invention, but should be understood as including all changes, equivalents and even substitutions falling within the spirit and technical scope of the present invention.

[0077] The same reference numerals in the drawings, especially the same reference numerals with tens digits and ones digits or tens digits, ones digits and letters indicate components with the same or similar functions, and in the absence of special instructions , the components indicated by the reference numerals in the drawings can be understood as components complying with the above principles.

[0078] but, figure 1 and figure 2 The reference number of the first drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com