Integrated profile tube of compact spinning device in ring spinning frame

A technology of spinning frame and special-shaped tube, which is applied in spinning frame, textile and papermaking, drafting equipment, etc. The effect of running precision, improving yarn quality and accurate installation position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

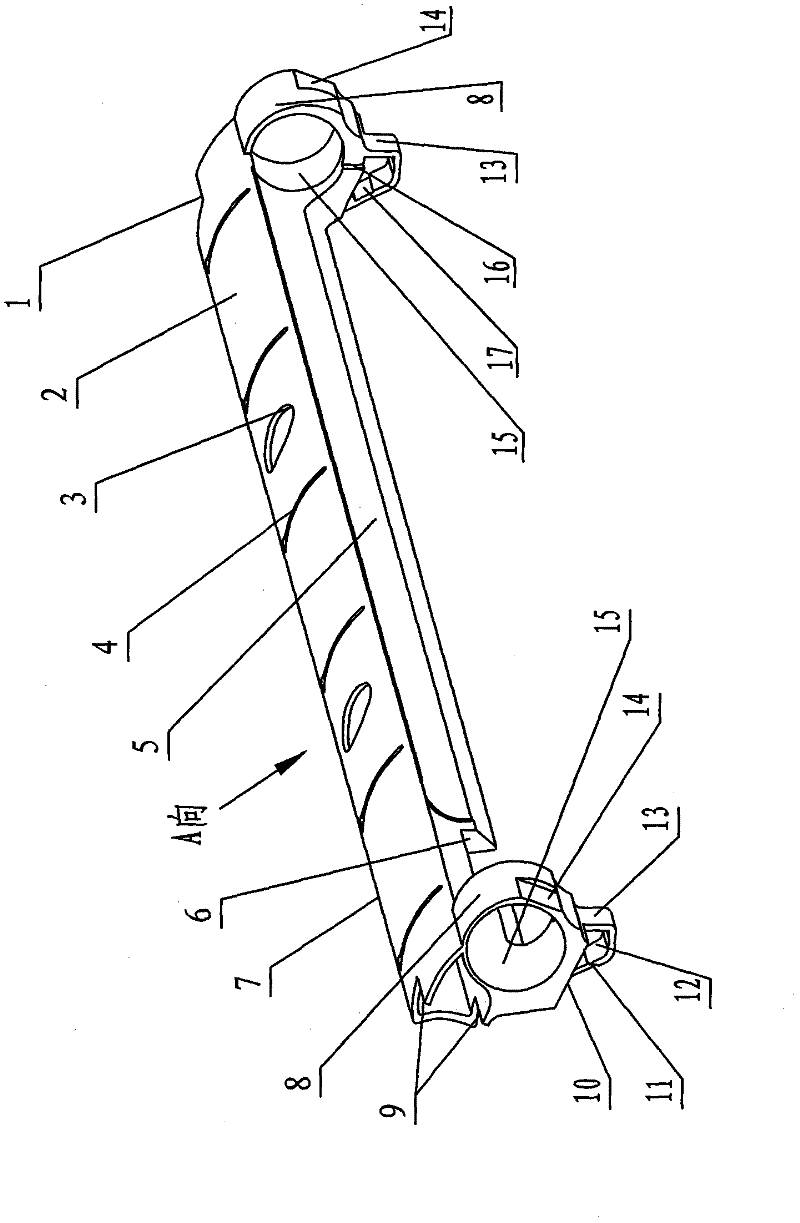

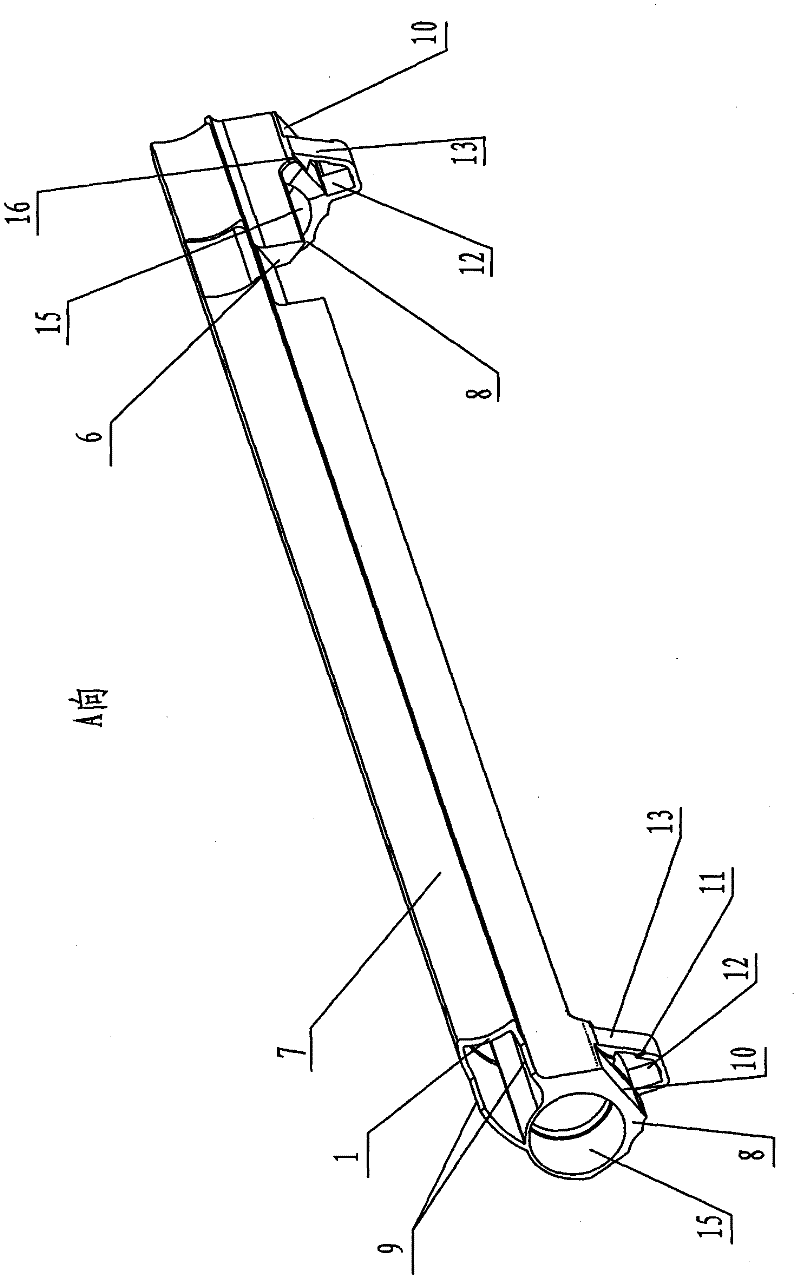

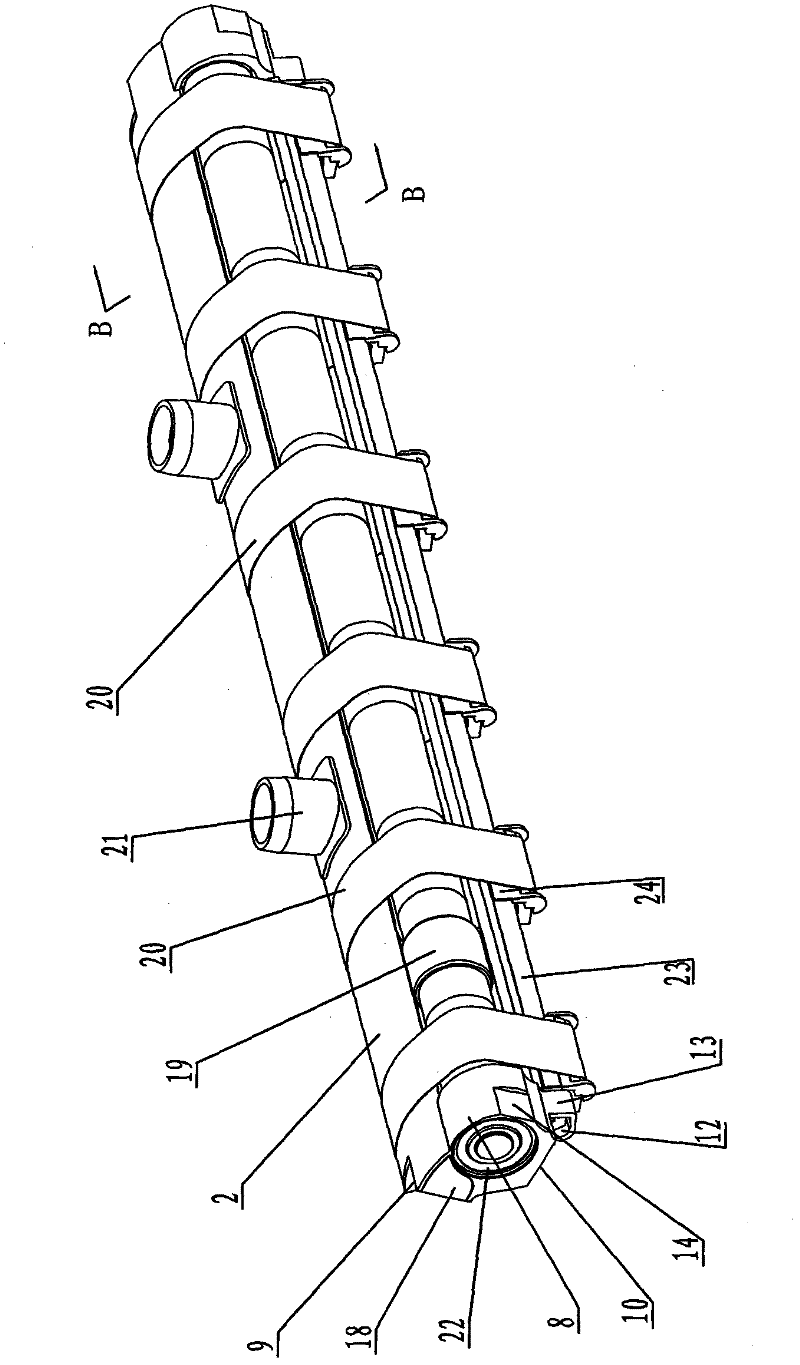

[0013] See Figure 1~3 As shown, the integrated special-shaped tube of the compact spinning device in the ring spinning frame of the present invention includes a negative pressure compact tube 2, the two ends of the negative pressure compact tube 2 are respectively provided with gaps 1, and the plugs 18 at both ends are sealed and installed in the negative pressure tube. There is 1 notch at both ends of the collecting pipe 2, and the rear positioning surface 9 of the end surface intersecting the longitudinal section at the notch 1 can match the positioning surface on the installation groove on the roller seat, and pass through the ends installed at both ends of the negative pressure collecting pipe 2. Plug 18 can not leak to keep the negative pressure air flow of negative pressure collecting pipe 2, and the pipe wall of negative pressure collecting pipe 2 along the guide surface is provided with at least one suction hole 3 and the airflow guide more than three that communicate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com