High-performance polycarboxylate water reducing agent and low-temperature one-step preparation method thereof

A technology of polycarboxylate and water reducing agent, applied in the field of concrete admixtures, can solve the problems of high production cost, high reaction temperature, long reaction period and the like, and achieve the effects of simple operation, good dispersion performance and high cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

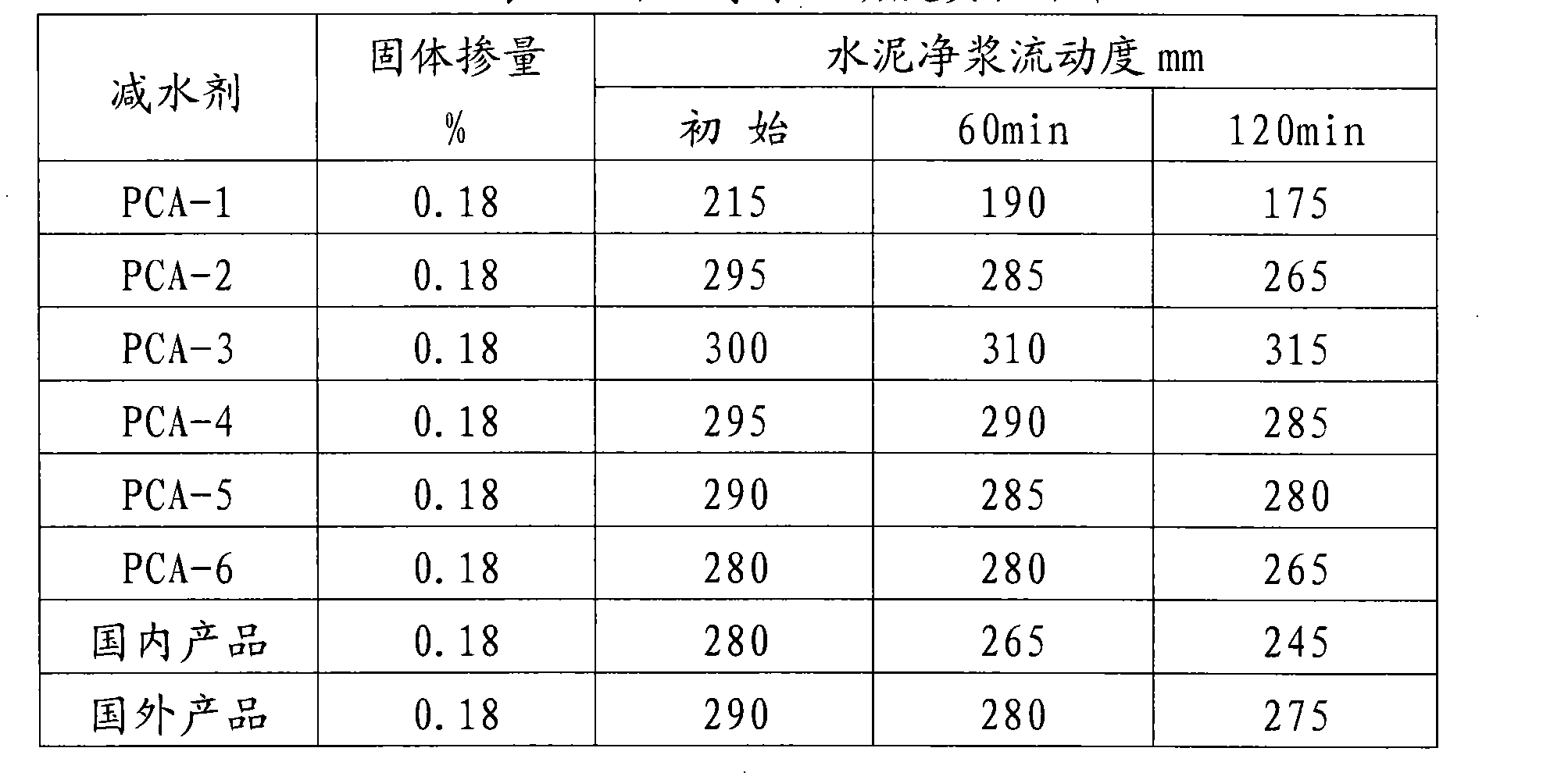

Examples

Embodiment 1

[0027] Add 345.6 g of deionized water and 433.7 g of macromonomer propylene alcohol polyoxyethylene ether into a 1000 mL four-necked flask equipped with an electric stirrer, a thermometer, a condenser, and a dropping device, and heat and stir to dissolve them.

[0028] At a temperature of 40° C., add 16.05 g of 27.5% hydrogen peroxide and stir evenly.

[0029] Thereafter, 94.7 g of an aqueous acrylic acid solution having a concentration of 70% was added dropwise to the reaction flask over 3 hours. At the same time, a mixed solution of 1.25 g of ascorbic acid, 2.3 g of thioglycolic acid and 110 g of deionized water was added dropwise to the reaction flask within 3.5 hours.

[0030] After the dropping, the reaction was continued at 40° C. for 2.5 hours.

[0031] Use 32% ionic membrane liquid alkali to adjust the pH at 6.0-7.0. Afterwards, it is diluted with water to the required concentration to obtain the product PCA-1.

Embodiment 2

[0033] Add 345.6 g of deionized water and 433.7 g of macromonomer isobutylene alcohol polyoxyethylene ether into a 1000 mL four-necked flask equipped with an electric stirrer, a thermometer, a condenser, and a dropping device, and heat and stir to dissolve them.

[0034] At a temperature of 40° C., add 16.05 g of 27.5% hydrogen peroxide and stir evenly.

[0035] Thereafter, 94.7 g of an aqueous acrylic acid solution having a concentration of 70% was added dropwise to the reaction flask over 3 hours. At the same time, a mixed solution of 1.25 g of ascorbic acid, 2.3 g of thioglycolic acid and 110 g of deionized water was added dropwise to the reaction flask within 3.5 hours.

[0036] After the dropping, the reaction was continued at 40° C. for 2.5 hours.

[0037] Use 32% ionic membrane liquid alkali to adjust the pH at 6.0-7.0. Afterwards, it is diluted with water to the required concentration to obtain the product PCA-2.

Embodiment 3

[0039] Add 345.6 g of deionized water and 433.7 g of macromonomer isopentenol polyoxyethylene ether into a 1000 mL four-necked flask equipped with an electric stirrer, a thermometer, a condenser, and a dropping device, and heat and stir to dissolve them.

[0040] At a temperature of 40° C., add 16.05 g of 27.5% hydrogen peroxide and stir evenly.

[0041] Thereafter, 94.7 g of an aqueous acrylic acid solution having a concentration of 70% was added dropwise to the reaction flask over 3 hours. At the same time, a mixed solution of 1.25 g of ascorbic acid, 2.3 g of thioglycolic acid and 110 g of deionized water was added dropwise to the reaction flask within 3.5 hours.

[0042] After the dropping, the reaction was continued at 40° C. for 2.5 hours.

[0043] Use 32% ionic membrane liquid alkali to adjust the pH at 6.0-7.0. Afterwards, it is diluted with water to the required concentration to obtain the product PCA-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com