Process for spraying patterns on bamboo or wood semi-finished product

A printing process and semi-finished technology, which is applied in the process of producing decorative surface effects, wood processing equipment, decorative art, etc., and can solve the pollution on the back of the printed product, the overlapping and void phenomenon of the finished product pattern, and the large difference in pattern error, etc. problem, to achieve the effect of bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

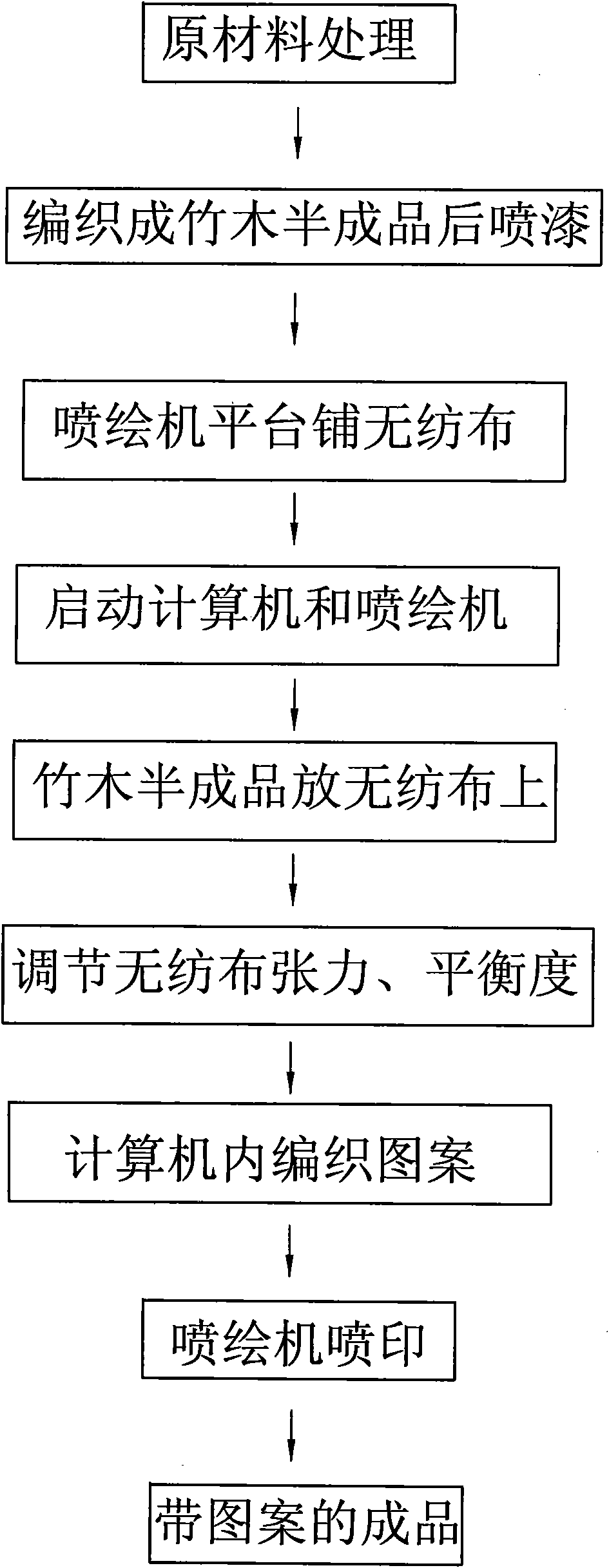

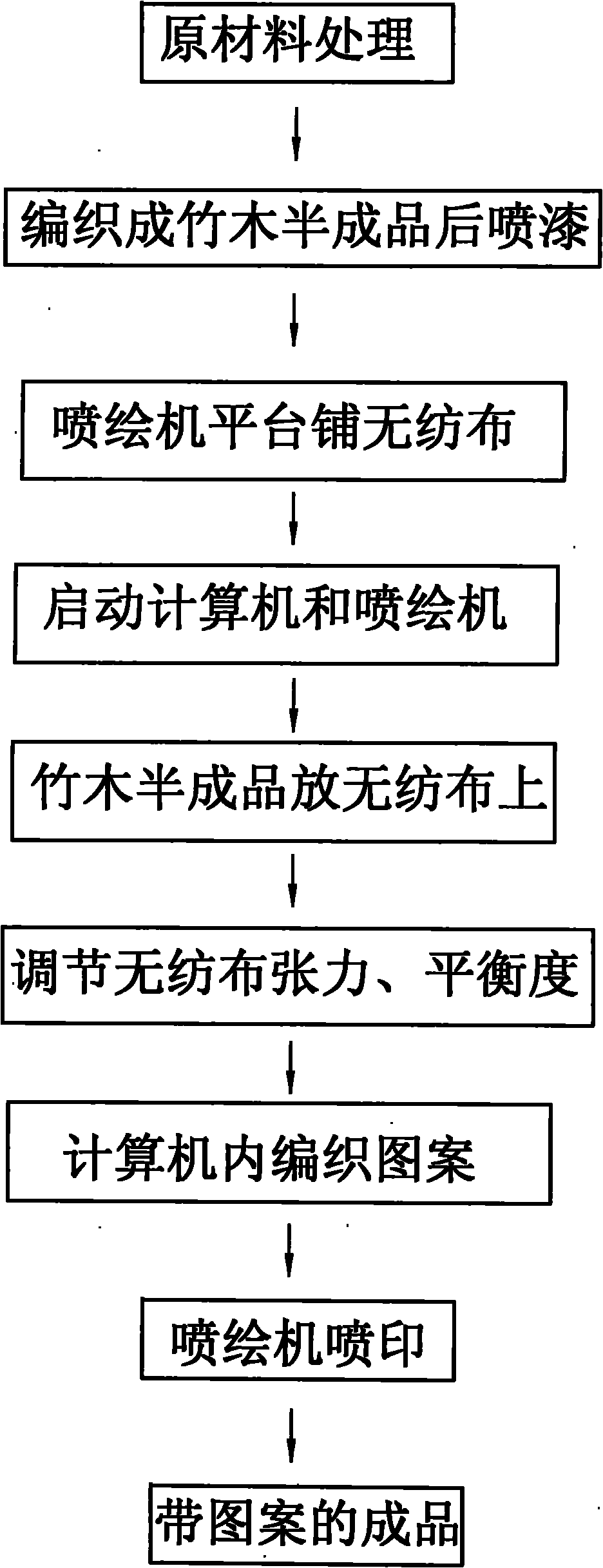

[0021] Such as figure 1 Shown, be used for the printing process on bamboo, wooden semi-finished product, described steps are as follows:

[0022] The first step: the raw materials of bamboo and wood are drawn into a garden shape through a mold, and then subjected to mildew-proof and moth-proof drying treatment;

[0023] The second step: Weaving into flaky bamboo and wood semi-finished products, and then spraying acrylic acid water-based paint on the flaky bamboo and wood semi-finished products;

[0024] The third step: spread non-woven fabric on the platform of the color inkjet printer, connect the data line of the inkjet printer to the computer, start the computer and the inkjet printer, and place the painted bamboo and wood semi-finished products on the non-woven fabric ;

[0025] The fourth step: start the manual adjustment device on one side of the inkjet printer and the infrared automatic adjustment device on the other side of the inkjet printer, and then adjust the ten...

Embodiment 2

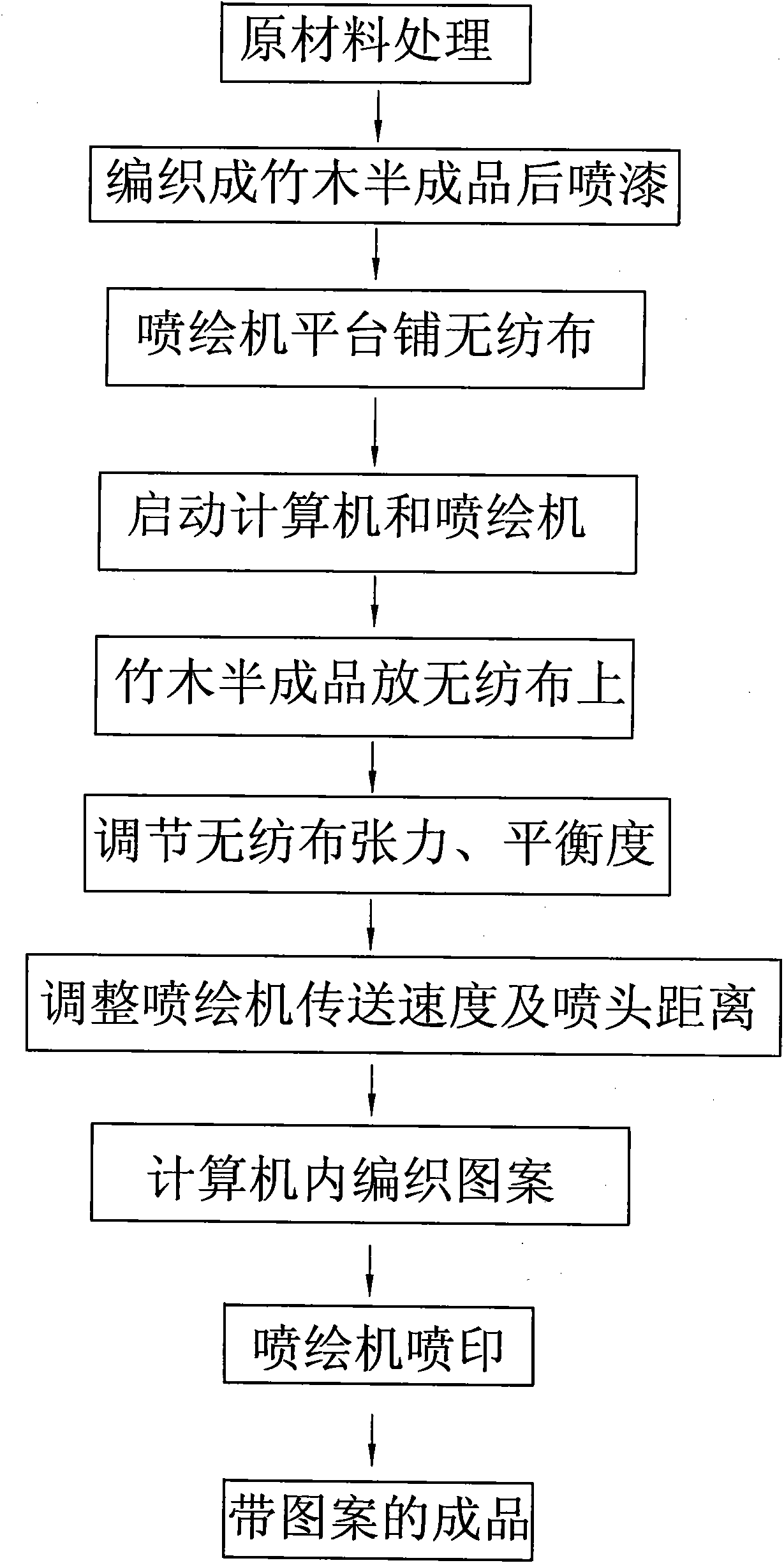

[0029] Such as figure 2 Shown, be used for the printing process on bamboo, wooden semi-finished product, described steps are as follows:

[0030] The first step: the bamboo and wood raw materials are pulled into a flat shape through a grinding tool, and then subjected to mildew-proof and moth-proof drying treatment;

[0031] The second step: Weaving into flaky bamboo and wood semi-finished products, and then spraying acrylic acid water-based paint on the flaky bamboo and wood semi-finished products;

[0032] The third step: spread non-woven fabric on the platform of the color inkjet printer, connect the data line of the inkjet printer to the computer, start the computer and the inkjet printer, and place the painted bamboo and wood semi-finished products on the non-woven fabric ;

[0033] The fourth step: start the manual adjustment device on one side of the inkjet printer and the infrared automatic adjustment device on the other side of the inkjet printer, and then adjust t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com