Welding tooling device for pillar frame of machine cabinet and assembly method of device

A technology of welding tooling and columns, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low welding precision, inability to realize automatic and mechanized welding, and unstable welding quality, so as to reduce physical strength labor, reduce the incidence of product mismatch, and avoid the effect of processing difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

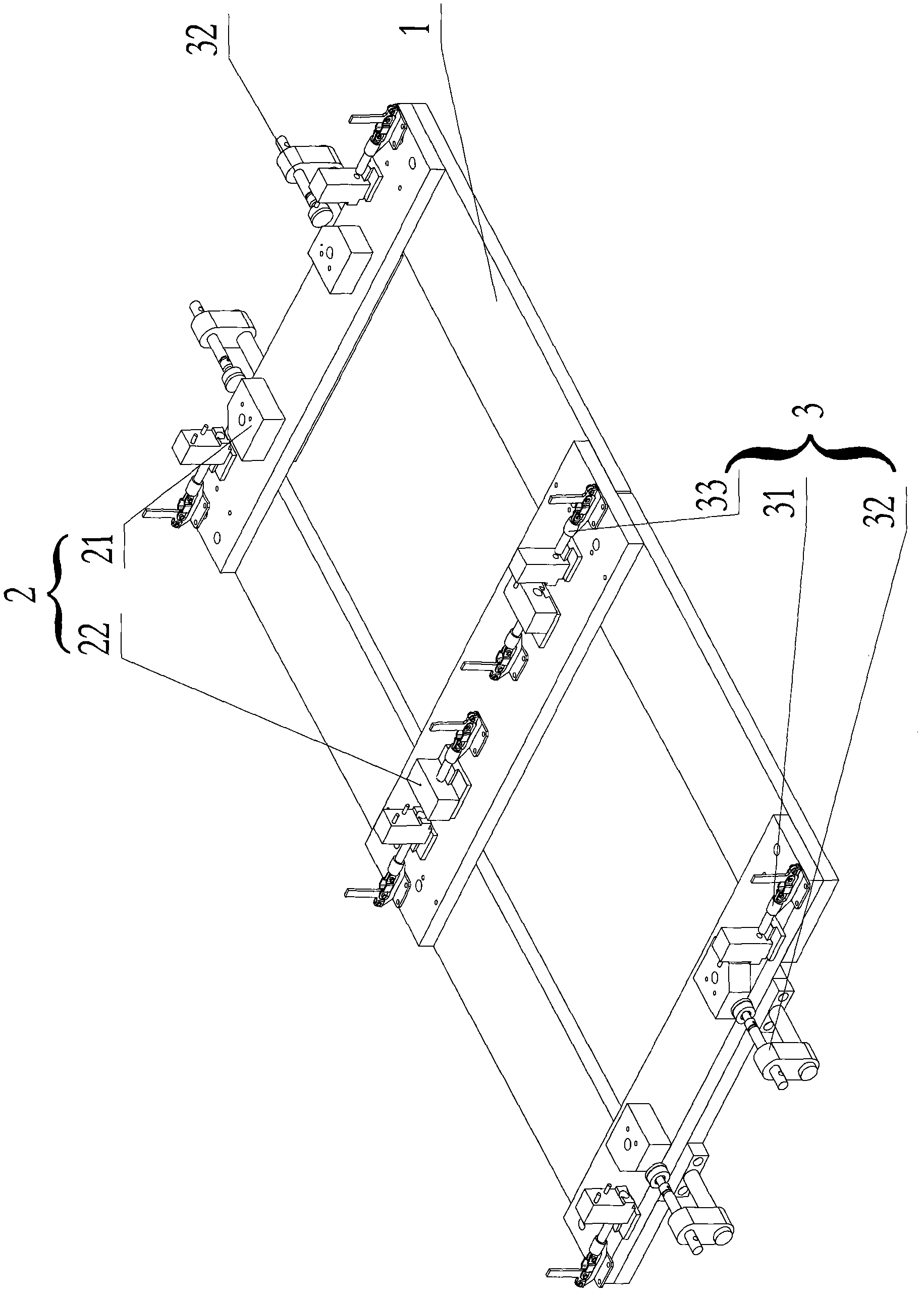

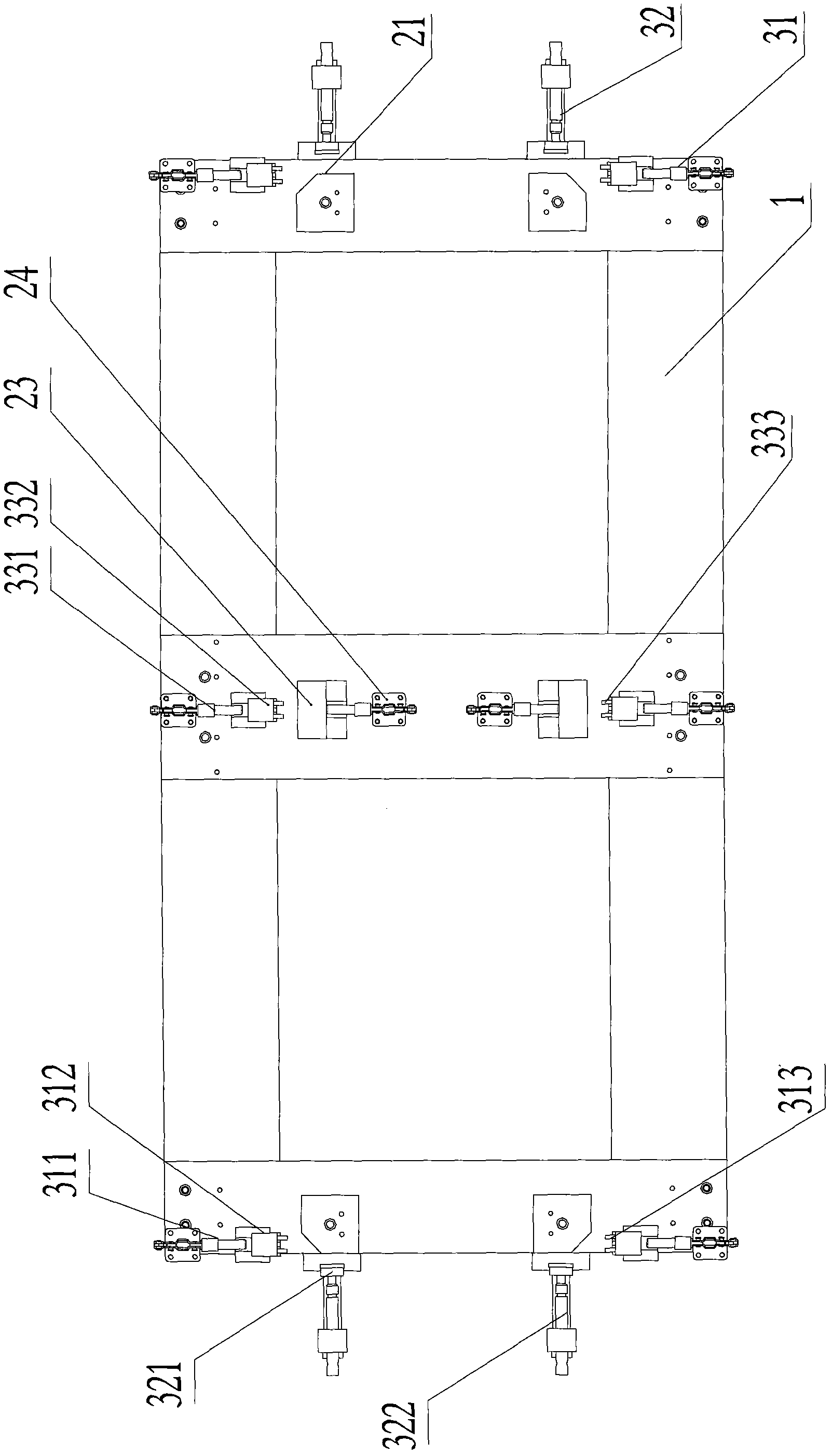

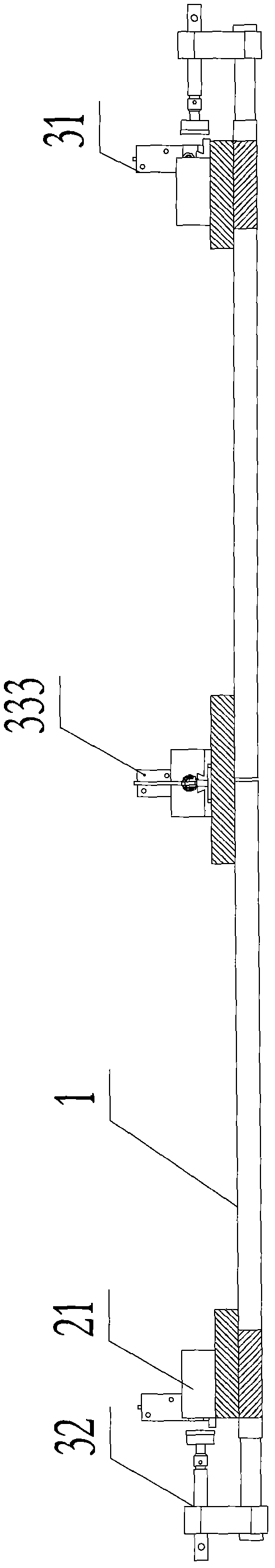

[0046] Such as Figure 1~6 As shown, the welding tooling equipment for the cabinet column frame includes a clamp body 1, on which a positioning element 2 and a clamping device 3 are fixedly arranged, and the positioning element 2 horizontally limits each component of the cabinet column frame, and the The clamping device 3 cooperates with the positioning element 2 to clamp the components of the column frame of the cabinet in the horizontal direction.

[0047] The frame 6 of the cabinet column includes a column 61, and connecting elements 62 are arranged at both ends of the column; the column and the connecting element form a frame, and several ear pieces 63 are arranged on the outside of the column. The part connection between the column 61 and the connecting element 62 and the part connection between the ear piece 63 and the column 61 need to be welded and fixed during the production process of the cabinet column frame.

[0048] The clamp body 1 is a bracket supporting the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com