Method for manufacturing edible oil

A manufacturing method and technology for edible oil, which are applied in the fields of edible oil/fat, application, food science, etc., can solve the problems of difficult and effective use of soft palm oil, and achieve good fresh flavor, not easy to turbidity and crystallization, and good cold resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

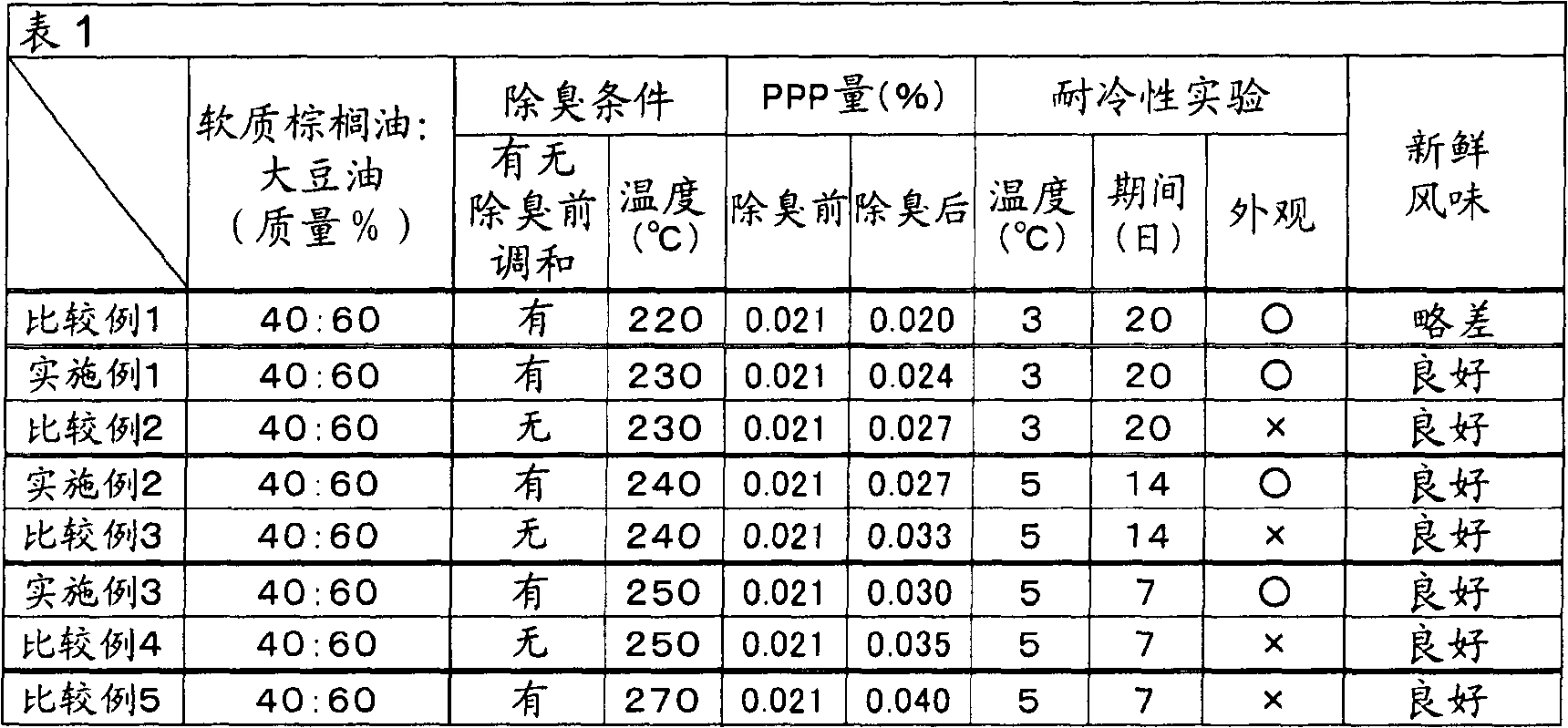

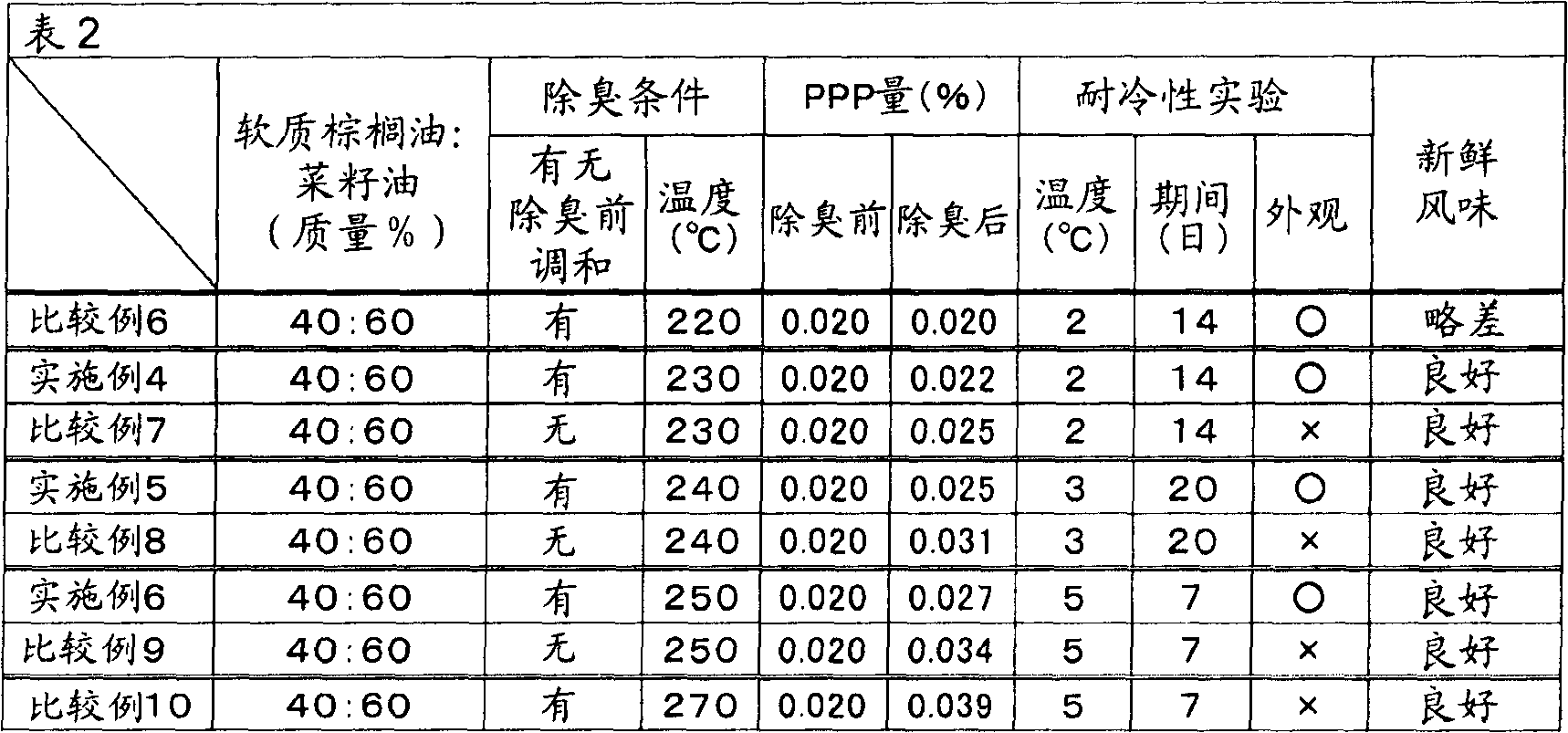

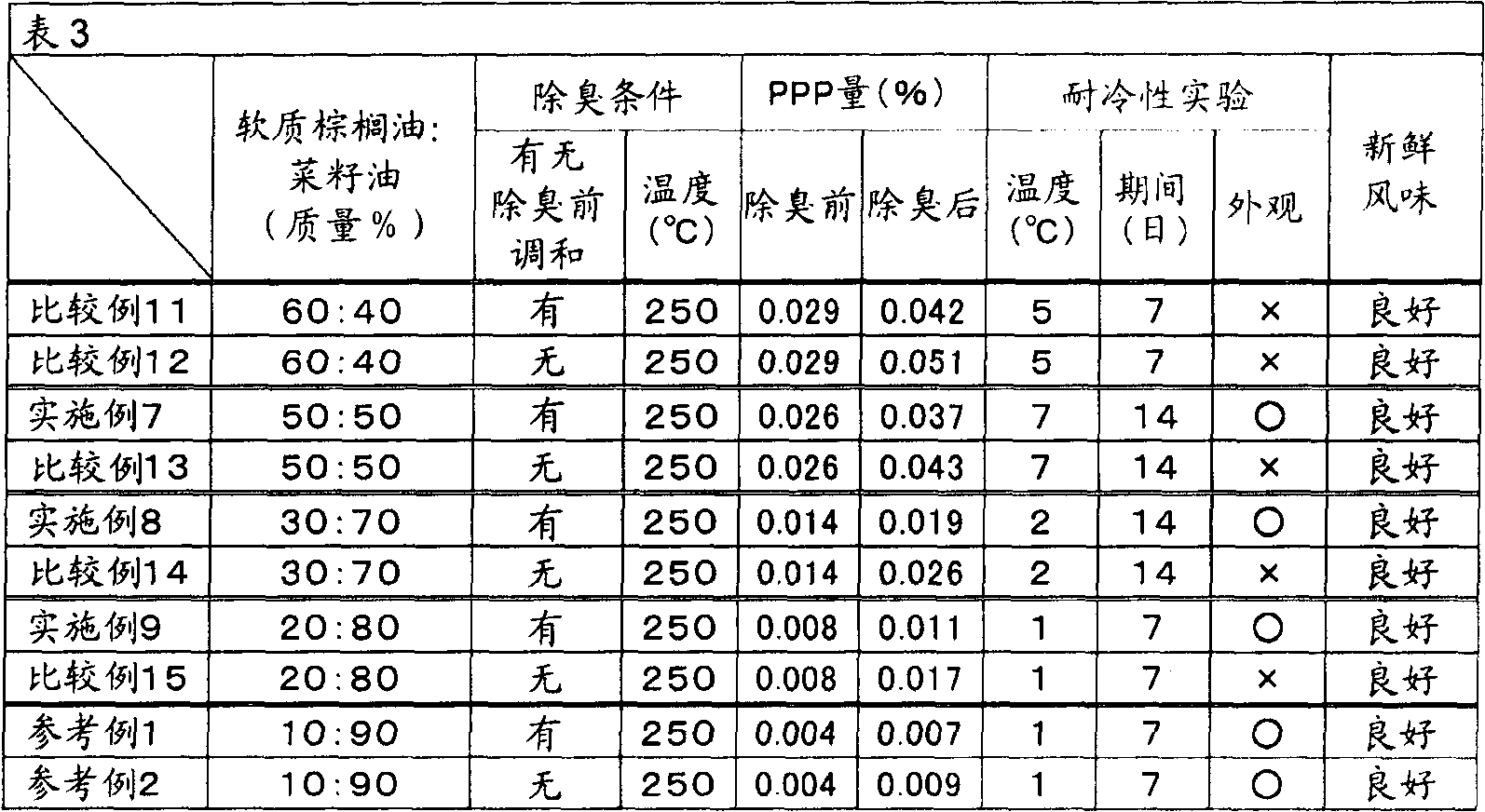

Examples

manufacture example 1

[0035] [Manufacturing example 1] Manufacturing method of soft palm oil (decolorized oil)

[0036] Carry out degumming treatment, decolorization treatment, deoxidation and deodorization treatment on palm crude oil, and classify the obtained oil, the RBD soft palm oil (RBD palm oleic acid oil, iodine value: 65, INTERCONTINENTAL SPECIALTY FATSSDN.BHD (manufactured by the company) was added 1.5% by mass of activated clay (manufactured by Mizusawa Chemical Industry Co., Ltd.) relative to the RBD soft palm oil, and stirred under reduced pressure at 110°C for 20 minutes to allow the pigment to adsorb, and then, filter The white clay is removed by the method to obtain a decolorized oil.

manufacture example 2

[0037] [Manufacturing example 2] Manufacturing method of soft palm oil (deodorized oil)

[0038] Into the palm oleic acid oil (decolorized oil) produced by the method of Production Example 1, water vapor of about 3% by mass relative to the decolorized oil was blown at a temperature of 220°C to 270°C under a vacuum of about 400 Pascals After 90 minutes (deodorization treatment), palm oleic acid oil (deodorization oil) was obtained.

manufacture example 3

[0039] [Manufacturing example 3] Manufacturing method of soybean oil (decolorized oil)

[0040] Phosphoric acid was added in an amount of 0.1% by mass to extracted soybean crude oil (amount of saturated fatty acid in component fatty acids: 15.6% by mass), and then 1.1 times the amount of hydrogen required to neutralize phosphoric acid and free fatty acid was added. Sodium oxide aqueous solution (concentration: 11%), and use centrifugation to remove gum and soap to obtain primary deoxygenated oil. Next, after adding 0.5% by mass of sodium hydroxide aqueous solution (concentration: 11%) to the above-mentioned primary deoxygenated oil, gum and soap were removed by centrifugation and washed with warm water to obtain deoxygenated oil. Then, 1.5% by mass of activated clay (manufactured by Mizusawa Chemical Industry Co., Ltd.) was added to the above-mentioned deoxygenated oil, and stirred for 20 minutes under reduced pressure at a temperature of 110° C. to adsorb the pigment, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com