Rotor position detection device

A rotor position detection and rotor technology, applied in the field of rotor position devices, can solve problems such as motor stop, rotation speed error, noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

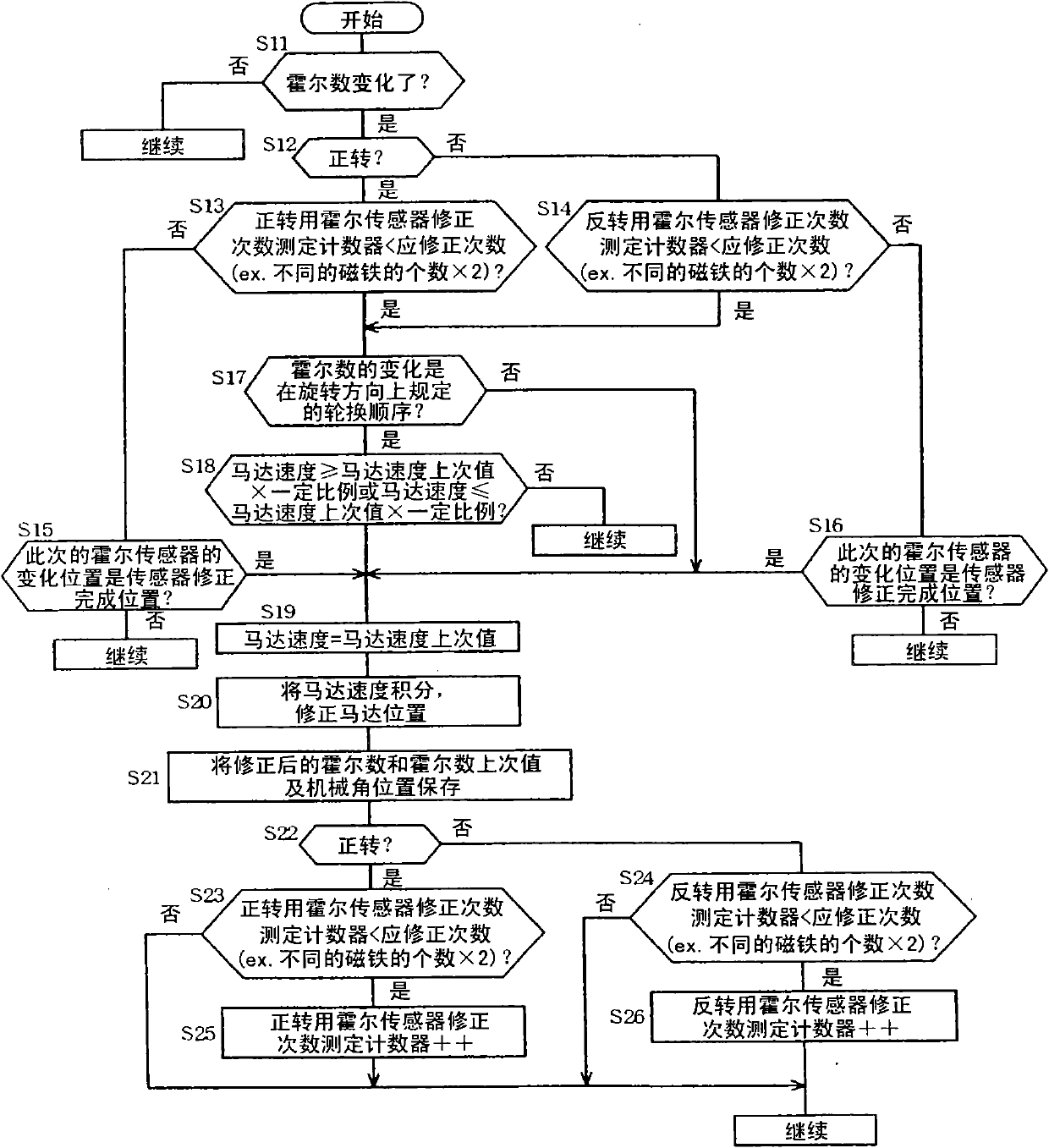

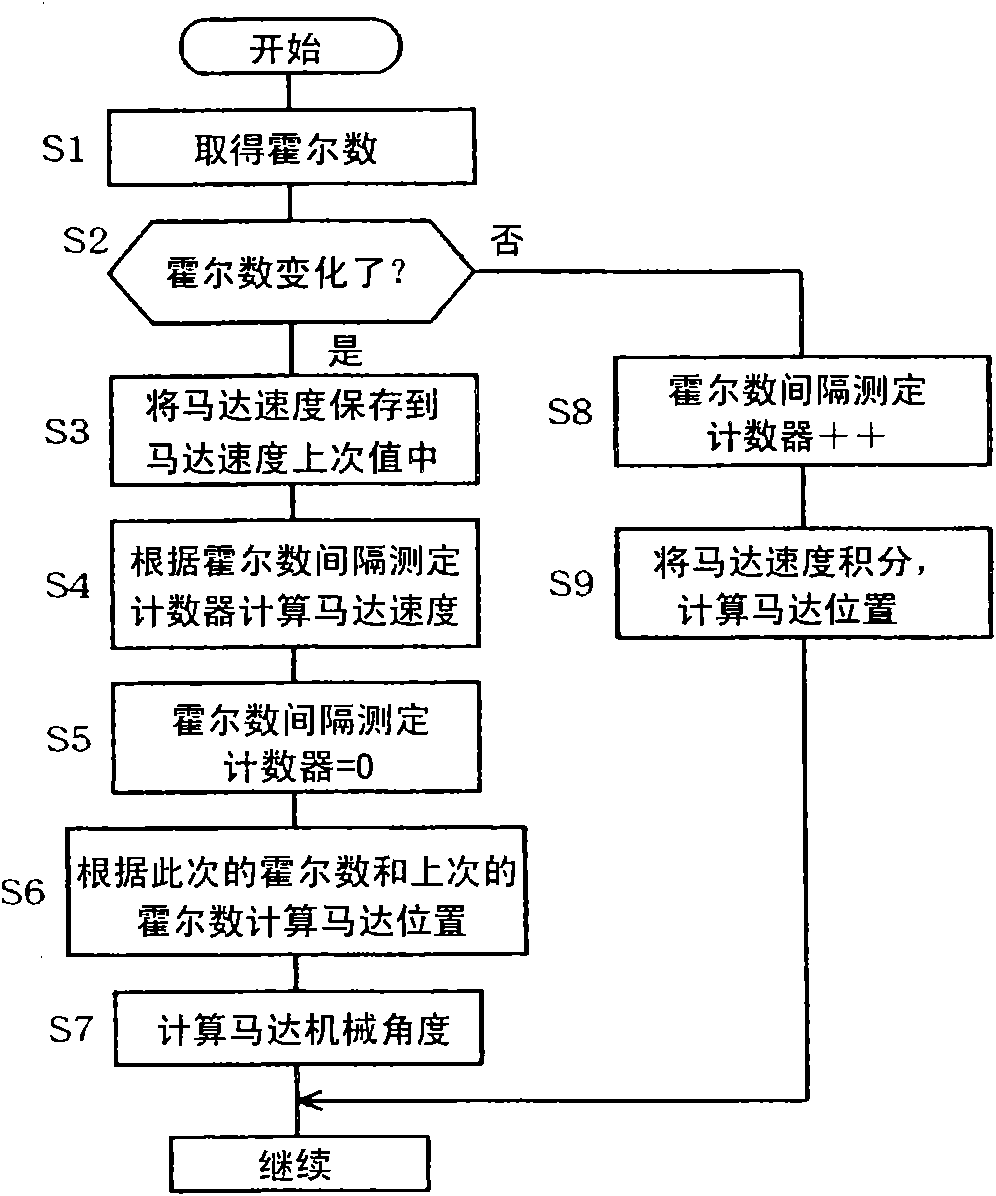

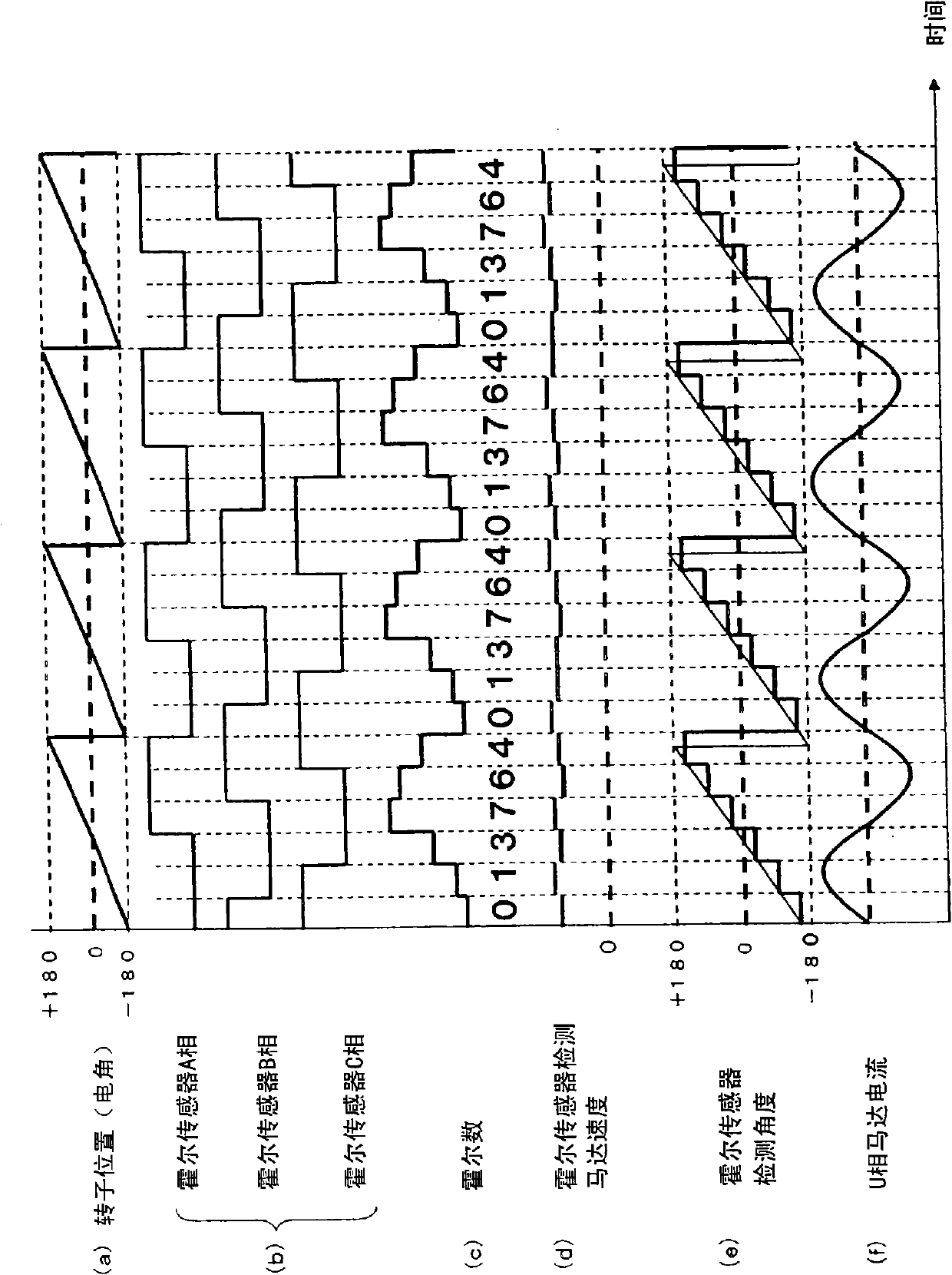

[0029] Below, refer to Figure 1 to Figure 12 An example will be described. Figure 8 It is a plan view showing the structure of the rotor of the permanent magnet motor 1 (outer rotor type brushless motor). A permanent magnet motor 1 is composed of a stator 2 and a rotor 3 provided on its outer periphery. The stator 2 is composed of a stator core 4 and a stator winding 5 . The stator core 4 is formed by laminating a plurality of die-cut soft magnetic silicon steel sheets, and has an annular yoke portion 4a and a plurality of teeth portions 4b protruding radially from the outer peripheral portion of the yoke portion 4a. . The surface of the stator core 4 is covered with PET resin (casting resin) except for the front end surface of each tooth portion (tees portion) 4 b.

[0030] In addition, a plurality of mounting portions 6 made of the PET resin are integrally formed on the inner peripheral portion of the stator 2 . These mounting parts 6 are provided with a plurality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com