Contact system of low-voltage circuit breaker

A contact system and circuit breaker technology, which is applied in the direction of circuit breaker contacts, circuit breaker components, circuit breaker switches with excessive current, etc., can solve the problems of electrical appliances burnout, re-ignition, and large repulsion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

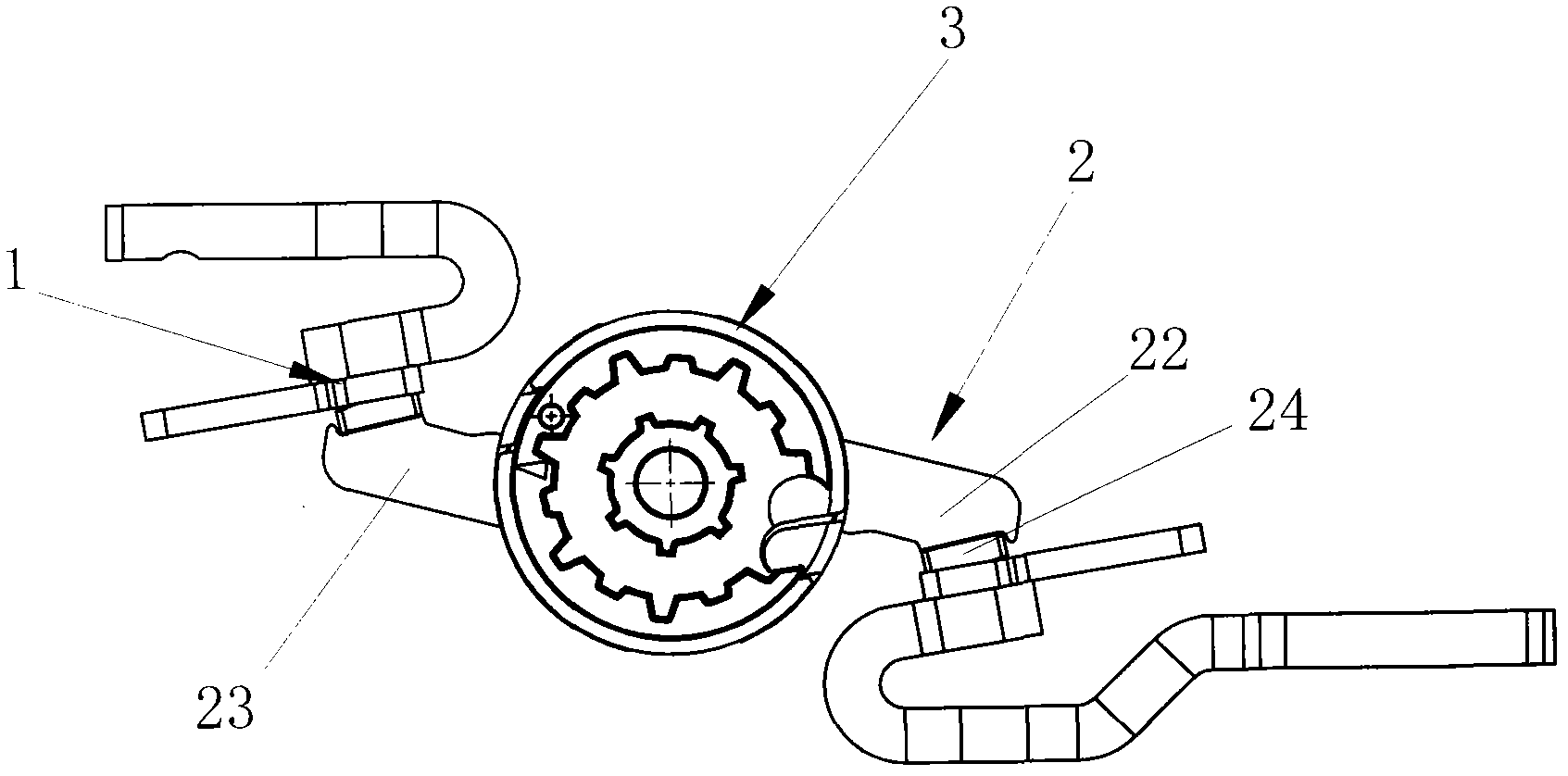

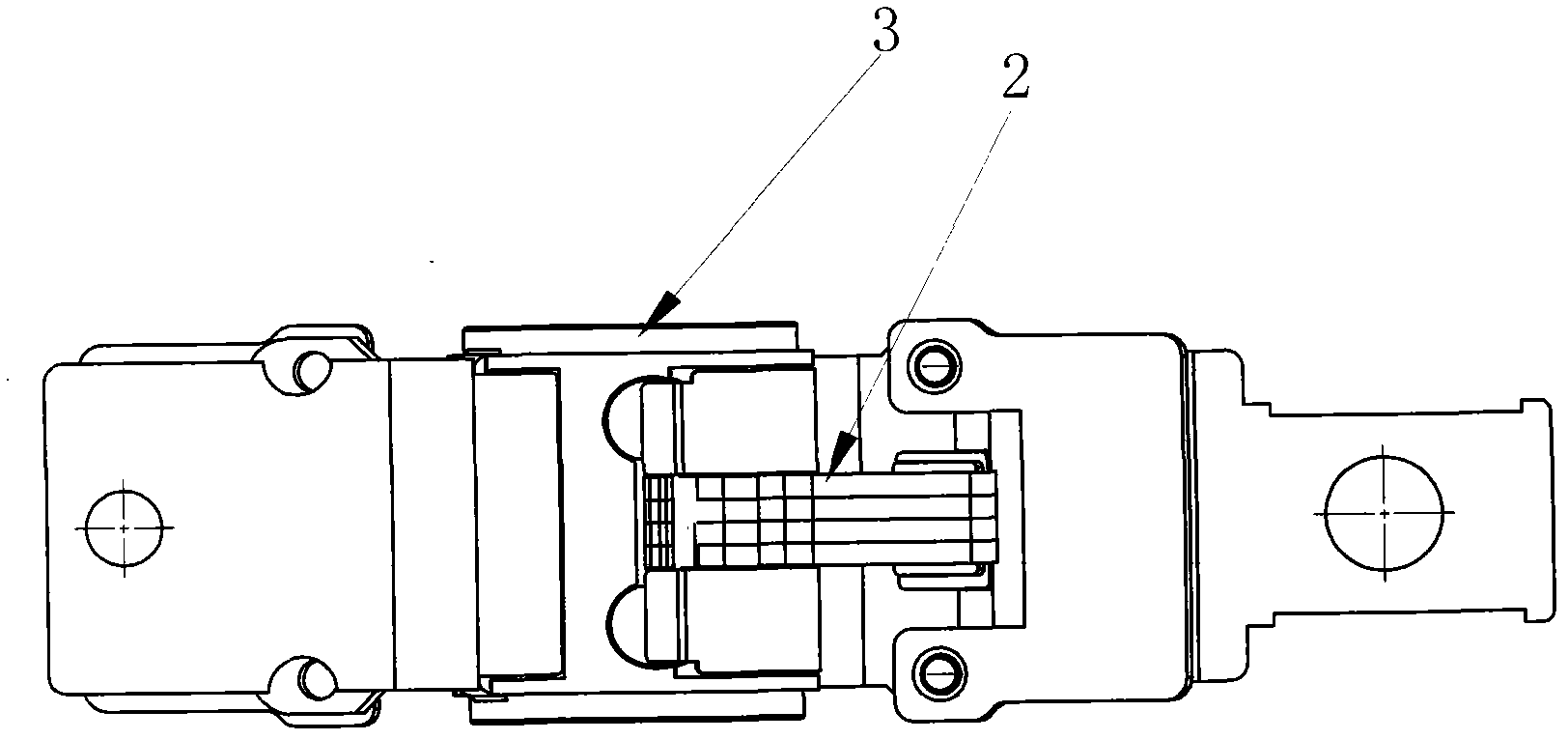

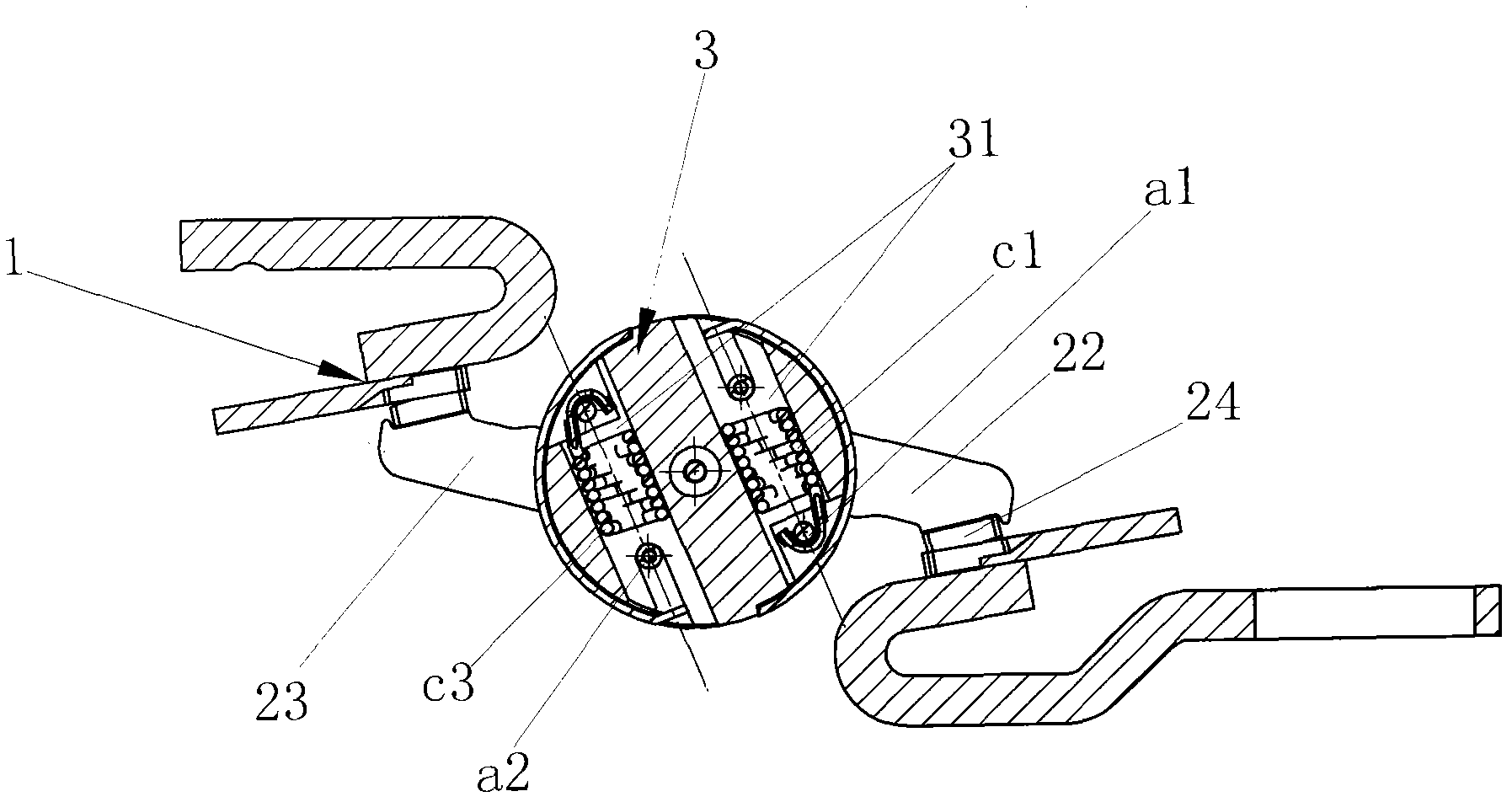

[0029] Such as Figure 1-17As shown, the specific embodiment of the present invention is a contact system of a double-contact circuit breaker, including two static contacts 1, one moving contact 2 and a moving contact support seat 3, wherein two static contacts The head 1 is electrically connected with corresponding input and output terminals respectively, and is used to be connected to a circuit; The two sides protrude, and the second moving contact piece 23 is arranged symmetrically with the above-mentioned first moving contact piece 22 relative to the rotation axis of the moving contact head 2, and is formed on the front ends of the first moving contact piece 22 and the second moving contact piece 23. The contact surface 24, the contact surface 24 can be connected or separated with respect to the static contact 1 through the rotation of the movable contact 2, and the first movable contact piece 22 and the second movable contact piece 23 are respectively formed on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com