Full-dry high fiber count air-blowing micro-cable and optical fibre bundle processing method

A technology of optical fiber bundle and large number of cores, applied in the direction of fiber mechanical structure, etc., can solve the problems of inability to meet the large number of cores, environmental pollution, etc., and achieve the effect of strong promotion and application value, avoiding environmental pollution, and increasing the number of optical fiber cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, preferred specific embodiment of the present invention is described:

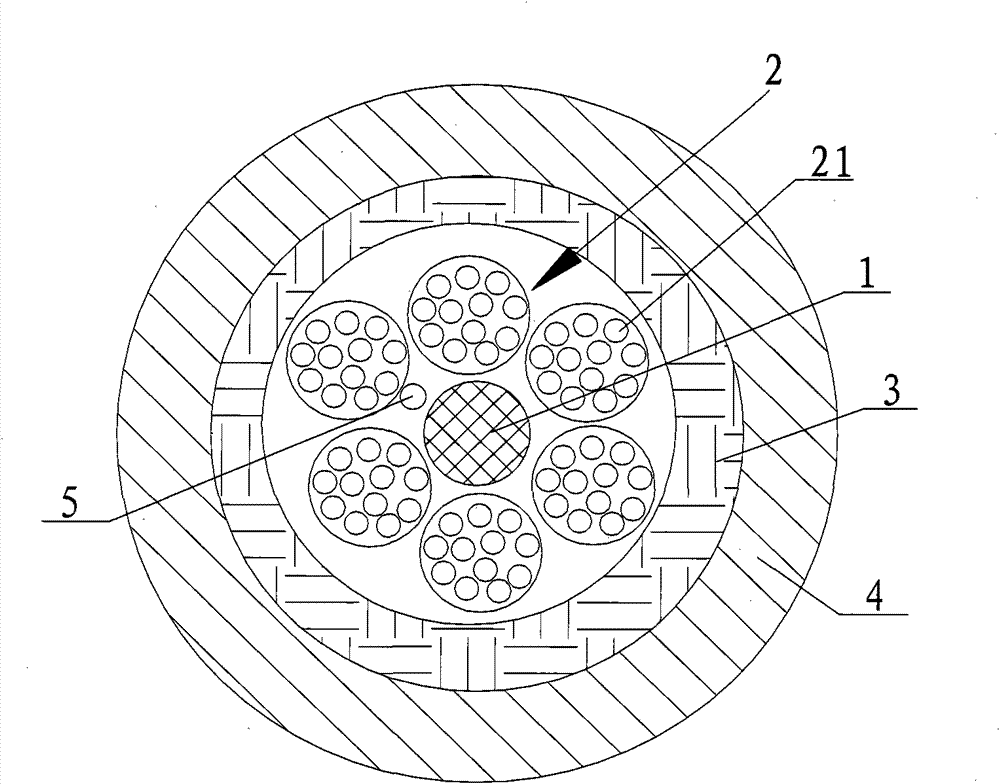

[0016] like figure 2 The air-blown air-blown microcable with large number of cores shown includes a plurality of optical fiber bundles 1, a non-metallic strength member 2 located in the center, a non-metallic tensile element 3 wrapped around the outer periphery of the optical fiber bundle 1, and an extruded anti- Polyethylene sheath 4 on the periphery of pull element 3 . Among them, a plurality of optical fiber bundles 1 are helically twisted and arranged on the non-metallic strengthening member 2, and the non-metallic tensile element 3 is realized by using aramid yarn.

[0017] A water-blocking yarn 5 is also arranged between the optical fiber bundles 1 to prevent moisture from entering the cable core.

[0018] In this embodiment, there are 6 optical fiber bundles 1, and each optical fiber bundle 1 is formed by curing 12 optical fibers 21. Certainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com