Method for eliminating edge effect of coated glass

An edge effect and coated glass technology, which is applied in the field of glass manufacturing, can solve problems such as difficult to fix the placement position, different glass specifications, and edge effects that cannot be solved, and achieve the effect of solving edge effects and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with the embodiment shown in the accompanying drawings, the technical scheme of the present invention is described in detail as follows:

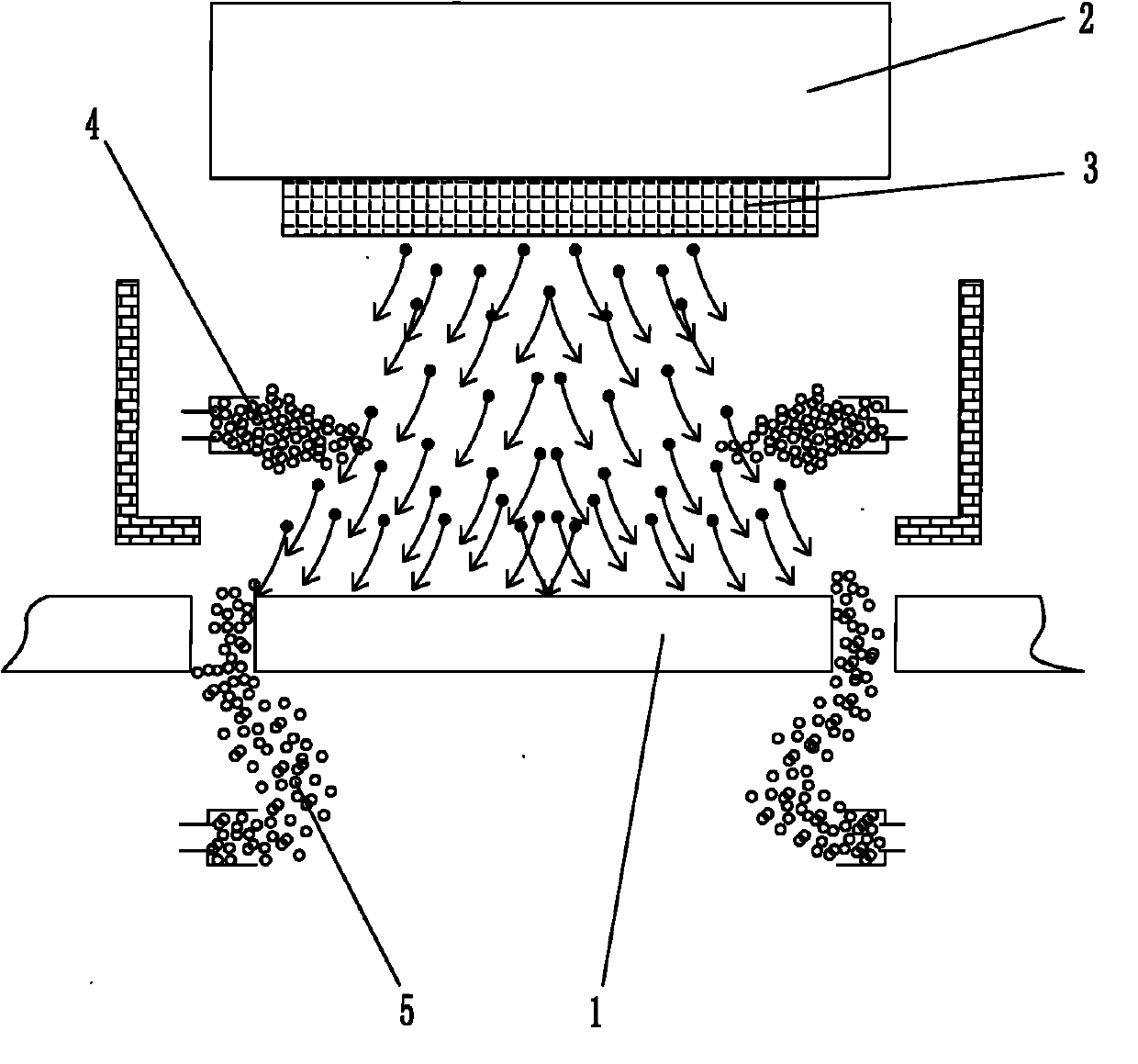

[0012] as attached figure 1 As shown, in the present invention, the magnetron sputtering method is used to deposit the atoms of the target material 3 adsorbed on the magnet 2 on the surface of the glass 1 to form a film layer, which is distributed on the sputtering channel of the target material 3 located above the glass 1. There is argon gas 4, and nitrogen gas 5 is distributed under the glass 1.

[0013] The argon gas 4 in the above-mentioned embodiment can also be selected from other inert gases, and the above-mentioned nitrogen gas 5 can also be replaced by oxygen gas.

[0014] In the above embodiment, without changing the original equipment and method, a process gas (oxygen or nitrogen, etc.) that slows down the sputtering is distributed under the glass, so that the sputtering speed of the edge of the glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com