Universal balance weight for railway tank car

A tank car and counterweight technology, which is applied to railway car body parts, tank cars, transport passenger cars, etc., can solve the problems of impact and poor safety when the counterweight rotates, and achieve the effect of high safety, low cost and adjustable weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

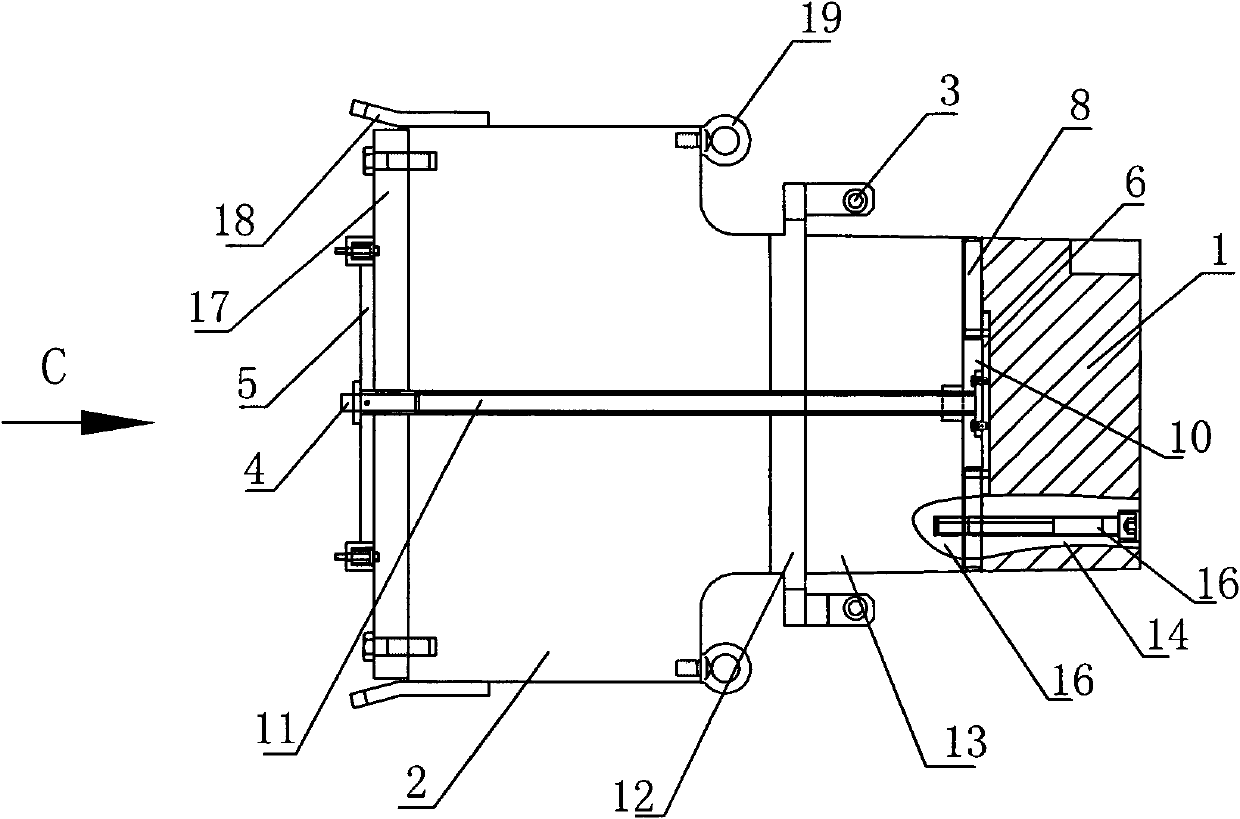

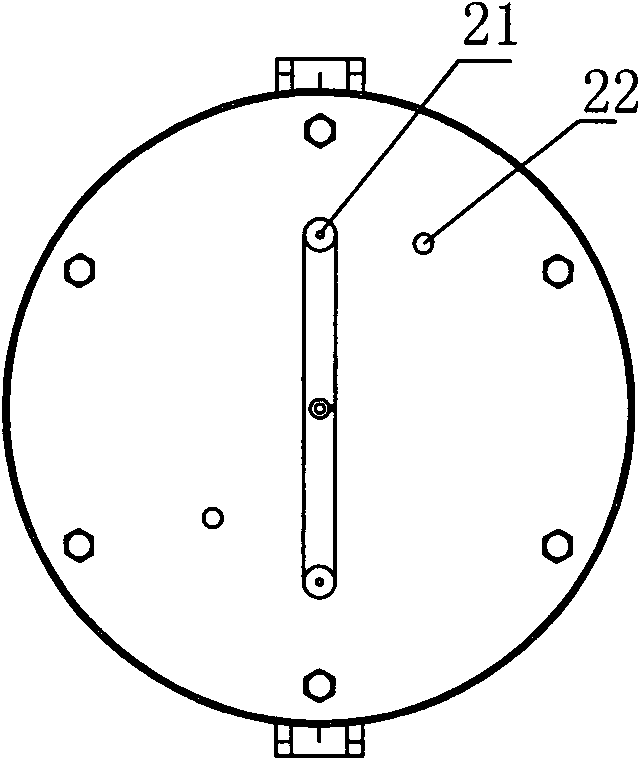

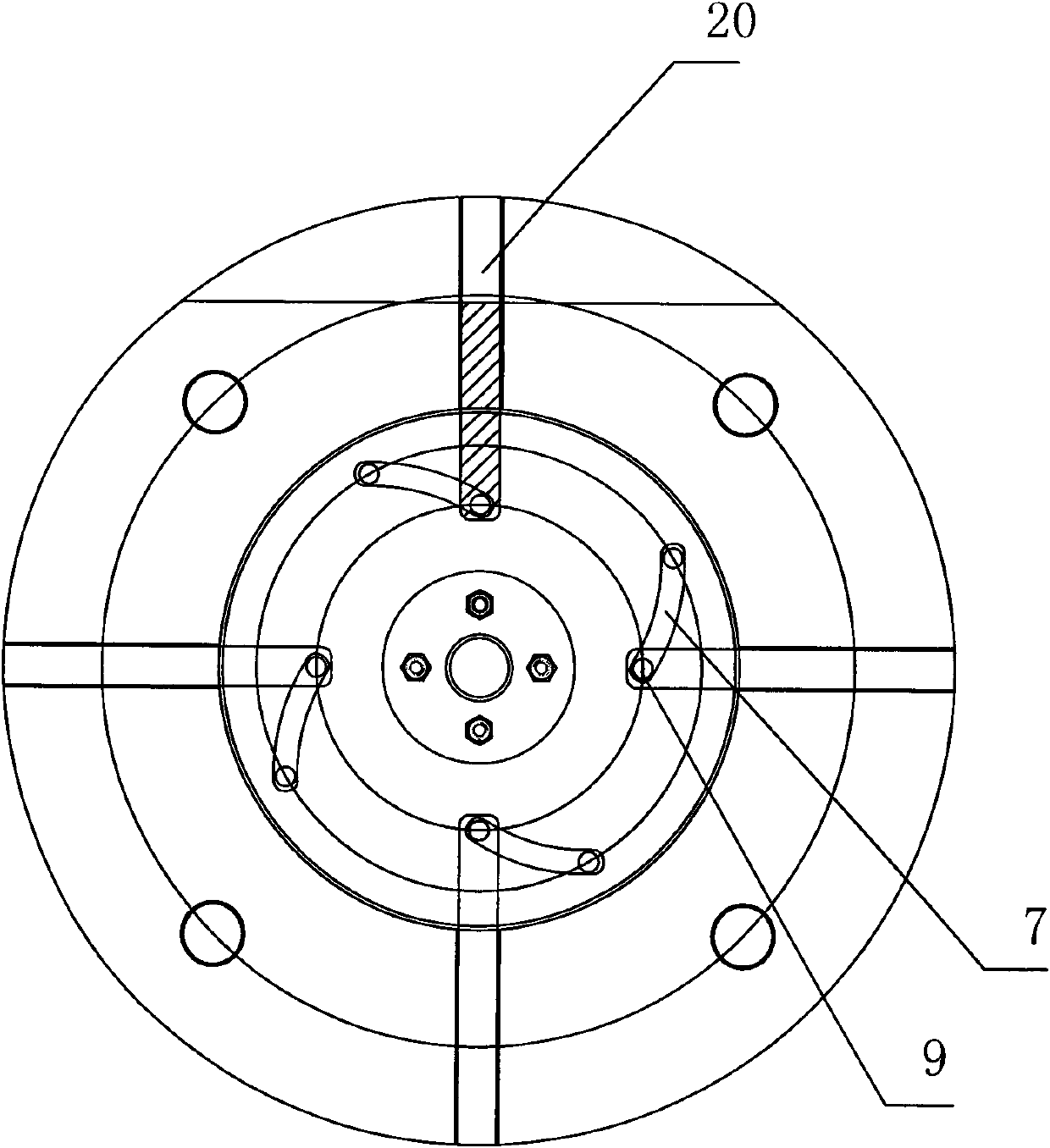

[0028] see figure 1 , 2 , 3, the adjustable universal counterweight of railway tank car of the present invention, comprises the inner counterweight 1 that can be loaded into the tank car manhole and the outer counterweight 2 that is arranged on the outside of the tank car manhole; Connect and fix the connecting piece on the tank car, the connecting piece is the first counterbore 3 arranged on the external counterweight 2, the first counterbore and the screw hole on the tank car are movably connected by screws, and the counterweight is fixed on the tank car. The structural form of parts also can adopt other movable connection modes in the prior art.

[0029] The inner counterweight 1 and the outer counterweight 2 of the present invention can be an integral structure or a split structure, that is, the inner counterweight 1 and the outer counterweight 2 can be made into a whole piece, or two relatively independent parts, when the inner counterweight When the weight 1 and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com