Automated elevated alcoholization library of cartons and cigarette packets

A technology for alcoholizing warehouses and cigarette packs, which is applied in the fields of tobacco, tobacco processing, transportation and packaging, etc., can solve the problems of low utilization rate of warehouse space, long allocation cycle, low storage rate, etc., and achieve fully automatic management and save configuration quantity. , the effect of increasing storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

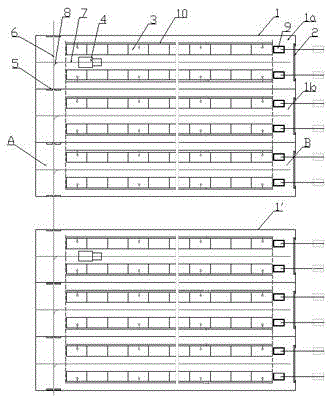

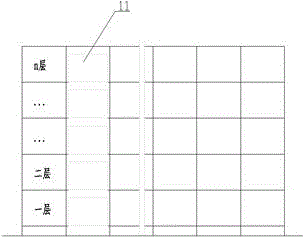

[0012] Such as figure 1 Shown, the present invention comprises the storeroom 1 with storehouse door 2, is arranged on the high-rise shelf 3 in the storehouse, the transition rail stacker 4 that is configured along the high-rise shelf. The warehouse includes one or more independent partitions 1a, 1b, ..., and each partition is provided with a pipeline for feeding and discharging insecticidal gas and has an independent warehouse door. Openable and closable airtight door 5 is provided between every adjacent two partitions, when a certain desinsection partition needs desinsection, closes the airtight door, can prevent the diffusion of desinsection gas, does not affect the normal operation of other desinsection partitions. On both sides of the warehouse, there are respectively a transition area A of the transition stacker and a warehouse area B for entering and exiting cigarette packs; the transition stacker completes the transition action in the transition area. The unloading, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com