Thin film forming method and film forming apparatus

A film-forming device and thin-film technology, which is applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problem that the thin film cannot be manufactured according to the design, and achieve the effect of cheap device cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

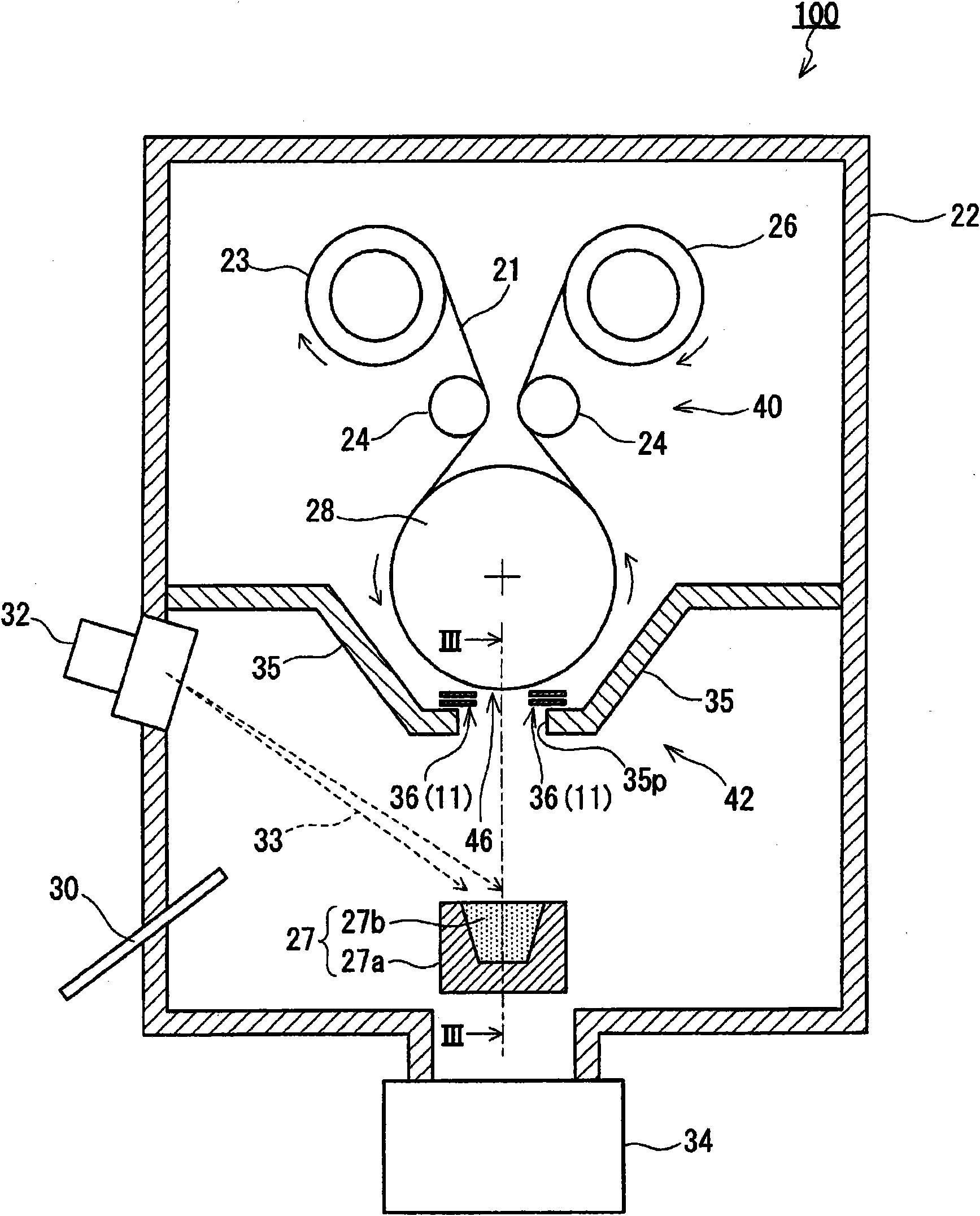

[0031] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. like figure 1 As shown, the film forming apparatus 100 of this embodiment has a vacuum chamber 22 , a substrate transfer unit 40 , a shielding unit 42 and a film forming source 27 . The substrate transfer unit 40 , the mask unit 42 and the film forming source 27 are arranged in the vacuum chamber 22 . A vacuum pump 34 is connected to the vacuum tank 22 . An electron gun 32 and a source gas introduction pipe 30 are provided on the side wall of the vacuum chamber 22 .

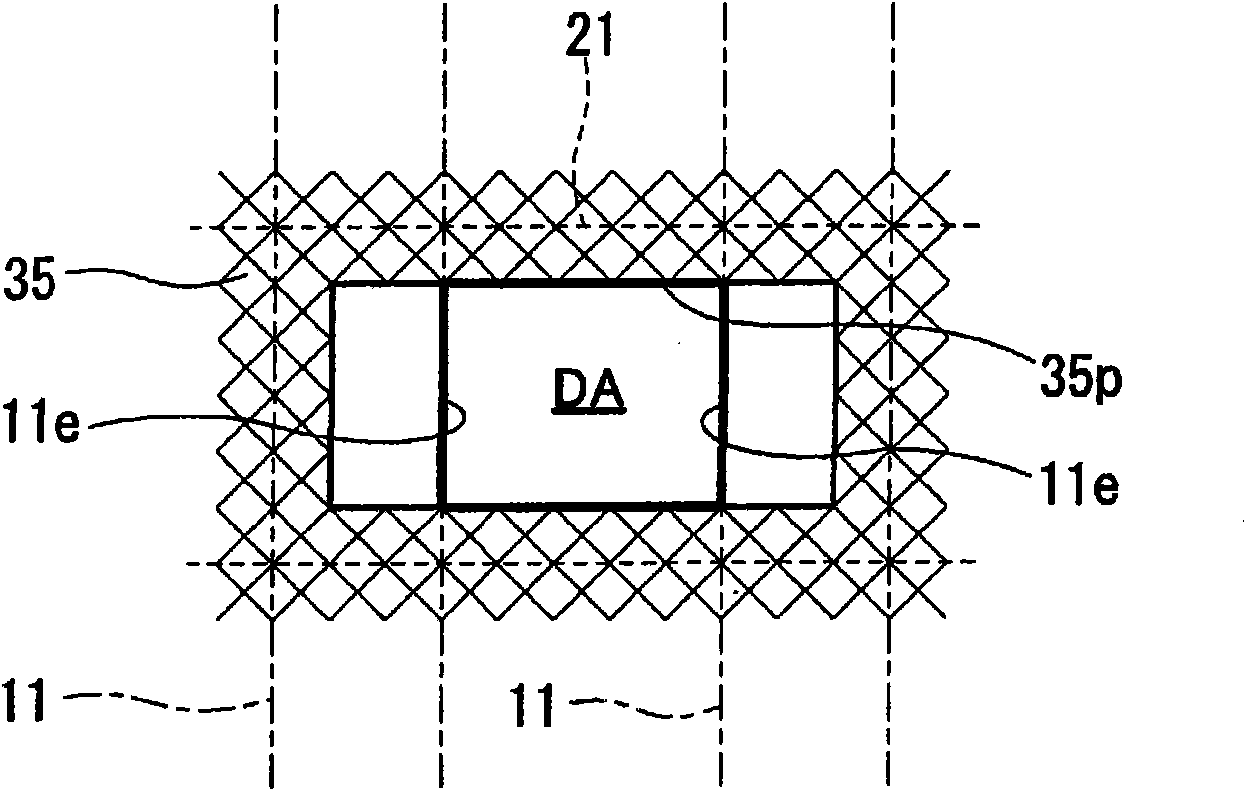

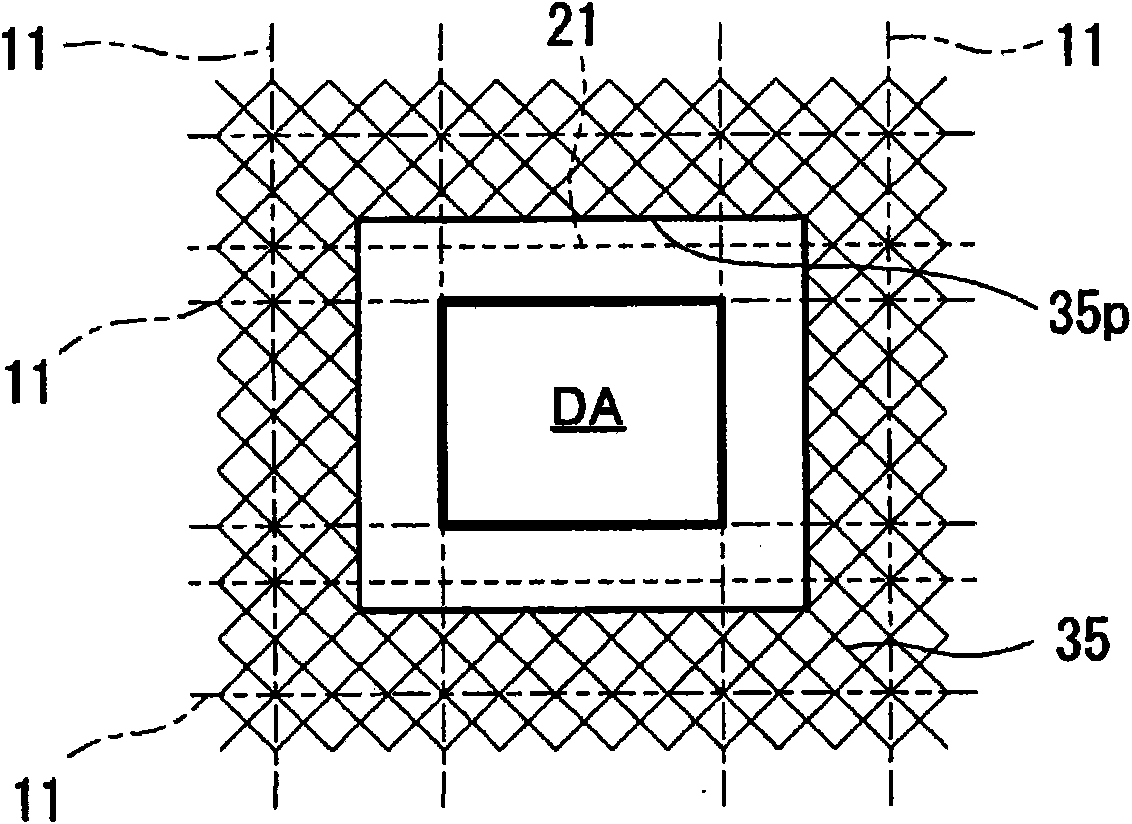

[0032] The shielding unit 42 is provided between the film forming source 27 and the substrate conveying unit 40 in such a manner as to limit the film forming region on the surface of the substrate 21 . The shielding unit 42 is composed of a fixed shielding plate 35 and a movable shielding mechanism 36 .

[0033] The fixed shielding plate 35 is installed in the vacuum chamber 22 . The fixed shielding p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com