Lead crimping device

A wire crimping and hydraulic technology, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problem of labor and labor, and achieve the effect of flexible and light use, shortened operation time and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

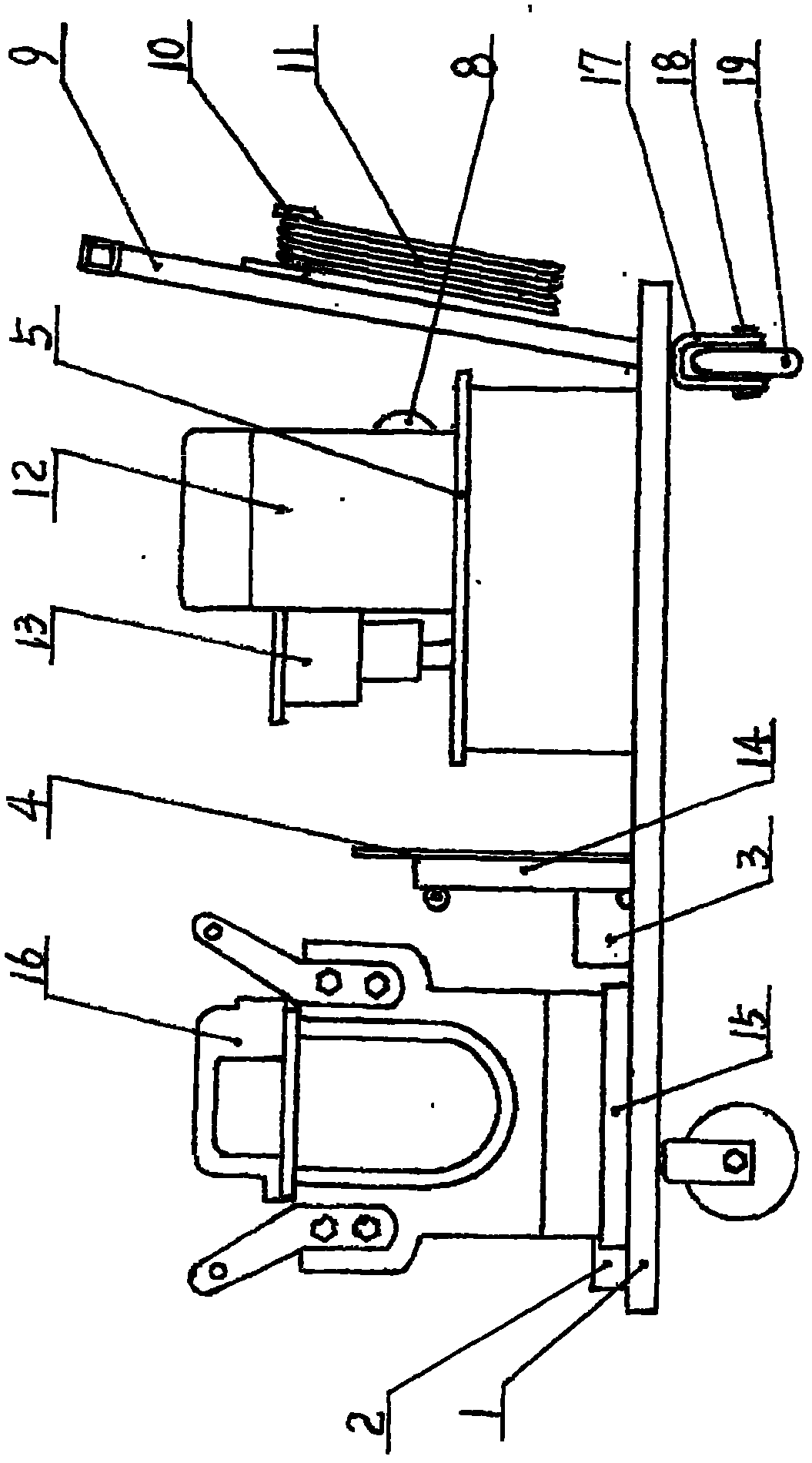

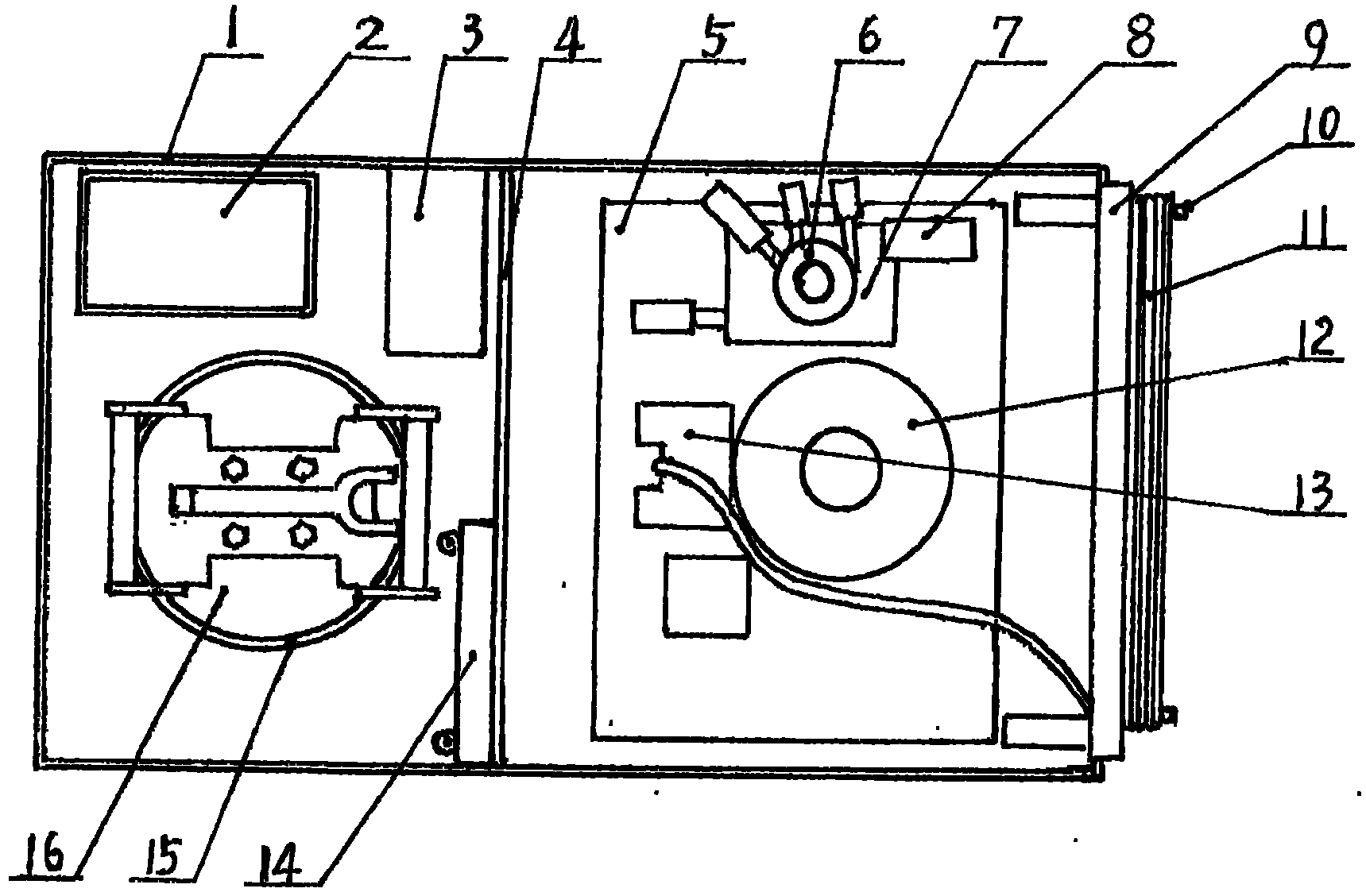

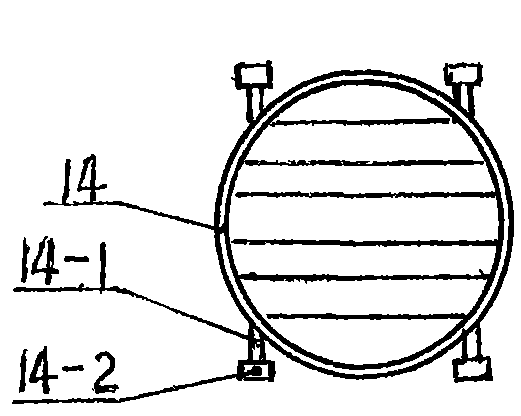

[0011] Examples, see attached Figure 1~3 , the car body of the wire crimping device is a rectangular body with an edge, there is no fixed push handle 9 at the right end of the car body 1, and a cable hook 10 is fixed outside the two vertical frames of the push handle 9, and the cable is hung on the hook 10. Line 11. A partition 4 is set in the middle of the car body 1, the right side of the partition 4 is fixed with a motor seat 5, the motor 12 and the valve seat 7 are fixed above the motor seat 5, and the valve 6 and the pressure gauge 8 are installed on the valve seat 7, and the motor 12 Motor switch 13 is installed on the left side. A movable hydraulic top seat 14 is placed in the middle of the left side of the dividing plate 4, and two hydraulic top seat shafts 14-1 are fixed below the hydraulic top seat 14, and top seat wheels 14-1 are mounted on both sides of the hydraulic top seat shaft 14-1. 2. After the mobile hydraulic top seat 14 is taken down, the hydraulic top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com