Low-concentration gas and ventilation air methane thermal oxidation generating system and method of coal mine

A low-concentration gas and power generation system technology, applied in the field of high-efficiency thermoelectric conversion, can solve the problems of unrealized large-scale application, large fluctuation range, and low gas concentration, so as to avoid excessive single-unit capacity, expand the concentration limit, and save energy. The effect of using water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

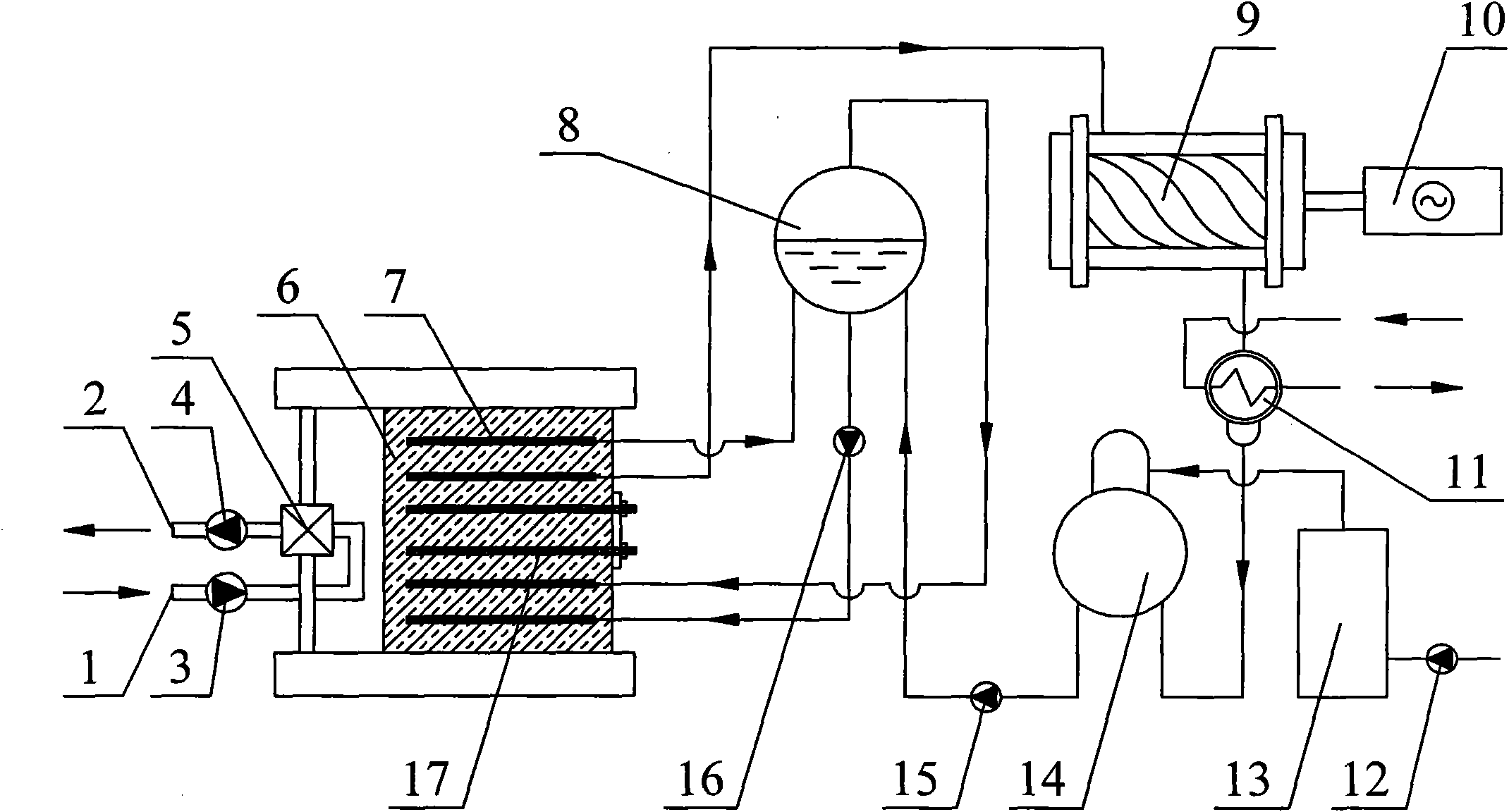

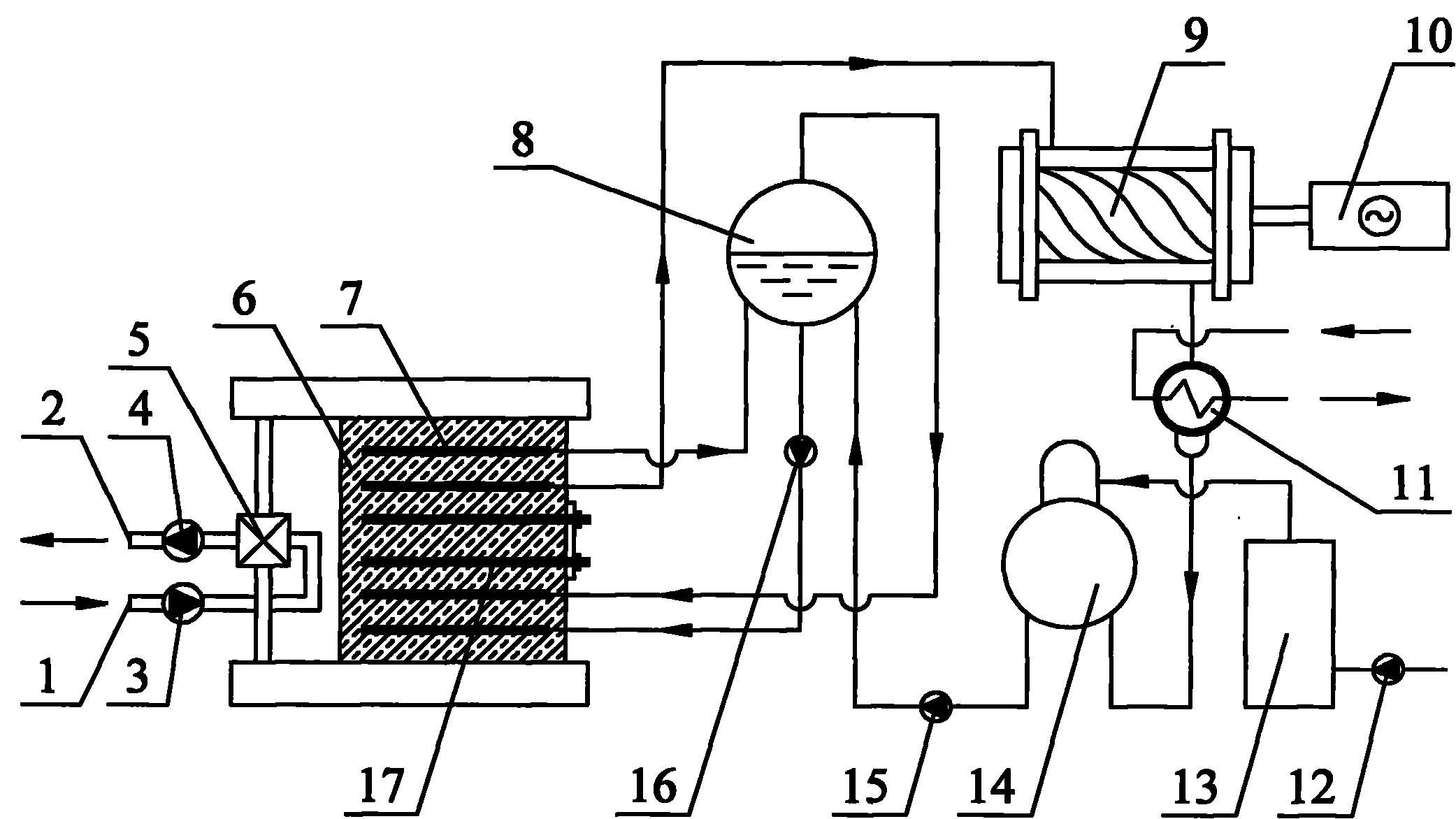

[0017] As shown in the accompanying drawings, the coal mine low-concentration gas and exhaust air gas thermal oxidation power generation system is mainly composed of a gas oxidation device, inlet and exhaust devices connected to the gas oxidation device, a circulating water treatment system, and a screw-type gas generator connected to the generator 10. The expander 9 is composed of an expander, wherein: the gas oxidation device includes a porous ceramic oxidation bed 6, a plurality of built-in heat exchangers 7 arranged in parallel at intervals on the upper and lower parts of the porous ceramic oxidation bed 6, and the middle part of the porous ceramic oxidation bed 6 is provided with at least one oxidation The bed starts the heater 17, and the ports of multiple built-in heat exchangers 7 are respectively connected to the drum 8 of the circulating water trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com