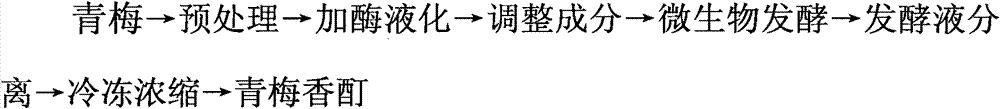

Method for preparing green plum fragrant tincture

A green plum tincture and green plum technology, which is applied in the field of flavor and fragrance processing, can solve the problems of large amount of ethanol, waste of raw materials, and increased cost, and achieve the effects of easy implementation, unique method, and high benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Pretreatment of Greengage

[0027] Fruit selection: pick out fresh and ripe greengage, wash and drain.

[0028] Blanching and beating: Soak the greengage in hot water at 100°C for 3 minutes, remove the core after soaking, and beat the pulp by conventional methods.

[0029] (2) Complex enzymatic hydrolysis

[0030] Add pectinase to the greengage pulp according to 0.07% of the mass of the greengage pulp obtained by beating, add cellulase according to 0.08% of the mass of the greengage pulp, and enzymolyze at 40° C. for 3 hours to obtain an enzymatic hydrolysis solution.

[0031] (3) Adjust ingredients

[0032] The enzymolysis solution is adjusted to 4% (m / v) with white granulated sugar, and sodium bicarbonate (NaHCO 3 ) to adjust the pH value of the enzymolysis solution to 4.5 to obtain a pretreatment solution.

[0033] (4) Microbial fermentation

[0034] Activated strains: select acid-resistant active dry yeast for brewing (including one or two commercially avai...

Embodiment 2

[0047] (1) Pretreatment of Greengage

[0048] Fruit selection: pick out fresh and ripe greengage, wash and drain.

[0049] Blanching and beating: Soak the greengage in hot water at 95°C for 5 minutes, remove the core after soaking, and beat the pulp by conventional methods.

[0050] (2) Complex enzymatic hydrolysis

[0051] Add pectinase to the greengage pulp according to 0.05% of the mass of the greengage pulp obtained by beating, add cellulase according to 0.07% of the mass of the greengage pulp, and enzymolyze at 50° C. for 2 hours to obtain an enzymatic hydrolysis solution.

[0052] (3) Adjust ingredients

[0053] Adjust the sugar content of the enzymolysis solution to 7% (m / v) with white granulated sugar, and adjust the pH value of the enzymolysis solution to 6.0 with sodium bicarbonate to obtain a pretreatment solution.

[0054] (4) Microbial fermentation

[0055] Activated strains: select acid-resistant active dry yeast for brewing (including one or two kinds of Aro...

Embodiment 3

[0068] (1) Pretreatment of Greengage

[0069] Fruit selection: pick out fresh and ripe greengage, wash and drain.

[0070] Blanching and beating: Soak the greengage in hot water at 100°C for 3 minutes, remove the core after soaking, and beat the pulp by conventional methods.

[0071] (2) Complex enzymatic hydrolysis

[0072] Add pectinase to the greengage pulp according to 0.08% of the mass of the greengage pulp obtained by beating, add cellulase according to 0.05% of the mass of the greengage pulp, and enzymolyze at 45° C. for 2.5 hours to obtain an enzymatic hydrolysis solution.

[0073] (3) Adjust ingredients

[0074] Adjust the sugar content of the enzymolysis solution to 1% (m / v) with white granulated sugar, and adjust the pH value of the enzymolysis solution to 3.5 with sodium bicarbonate to obtain a pretreatment solution.

[0075] (4) Microbial fermentation

[0076] Activated strains: select acid-resistant active dry yeast for brewing (including one or two kinds of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com