A microwave-infrared preparation method of carbonized aroma-enhancing feed raw materials

A feed raw material, microwave infrared technology, applied in animal feed, animal feed, food preservation, etc., can solve the problems of high loss of nutrients, poor taste of feed raw materials, easy oxidation and deterioration, etc., to achieve less loss of nutrients and less nutritional loss , the effect of promoting appetite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: The microwave infrared preparation method of a kind of carbonization flavor-enhancing type feed raw material of this example, its steps are:

[0020] a. Pour 51 kg of soybeans, 47 kg of oats, and 2 kg of salt feed materials into the conveyor belt and transport them to the box equipped with a microwave system. The microwave system is composed of a magnetron, a waveguide, and a radiator. The length of the box is different The microwave frequency is 433 MHz, the temperature is 90°C, and the power is not limited;

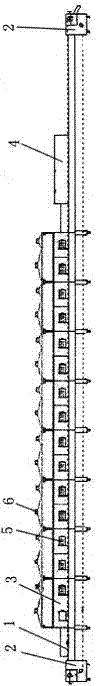

[0021] b. After the material comes out of the microwave box, it directly enters the box equipped with an infrared radiation heating system. The length of the box is not limited, the wavelength is 850 microns, the temperature is 110 ° C, the power is not limited, until the material is mature, and then cooled to room temperature, such as figure 1 , the microwave system and the infrared radiation heating system include a conveyor belt 1, a motor 2 is...

Embodiment 2

[0035] Embodiment 2: The microwave infrared preparation method of a kind of carbonization flavor-enhancing type feed raw material of this example, its steps are:

[0036] a. Pour 98 kg of wheat and 2 kg of glacial acetic acid into the feed material on the conveyor belt and transport it to the box equipped with a microwave system. The microwave system is composed of a magnetron, a waveguide, and a radiator. The length of the box is not limited. The wavelength is 12.2 cm, the frequency is 2450 MHz, the temperature is 130 ° C, and the power is not limited;

[0037] b. After the material comes out of the microwave box, it directly enters the box equipped with an infrared radiation heating system. The length of the box is not limited, the wavelength is 600 microns, the temperature is 140 ° C, the power is not limited, until the material is mature, and then cooled to room temperature, such as figure 1 , the microwave system and the infrared radiation heating system include a conve...

Embodiment 3

[0039] Embodiment 3: The microwave infrared preparation method of a kind of carbonization flavor-enhancing type feed raw material of this example, its steps are:

[0040]a. Pour 95 kg of barley and 5 kg of sodium hydroxide into the feed material on the conveyor belt and transport it to the box equipped with a microwave system. The microwave system is composed of a magnetron, a waveguide, and a radiator, etc. The length of the box is not limited. The microwave wavelength is 200mm, the temperature is 70°C, and the power is not limited;

[0041] b. After the material comes out of the microwave box, it directly enters the box equipped with an infrared radiation heating system. The length of the box is not limited, the wavelength is 100 microns, the temperature is 90 ° C, the power is not limited, until the material is mature, and then cooled to room temperature, such as figure 1 , the microwave system and the infrared radiation heating system include a conveyor belt 1, a motor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com