Bottle cap fold processing equipment

A processing equipment and bottle cap technology, which is applied in the field of bottle cap folding processing equipment, can solve problems such as low production efficiency, poor anti-theft performance, and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

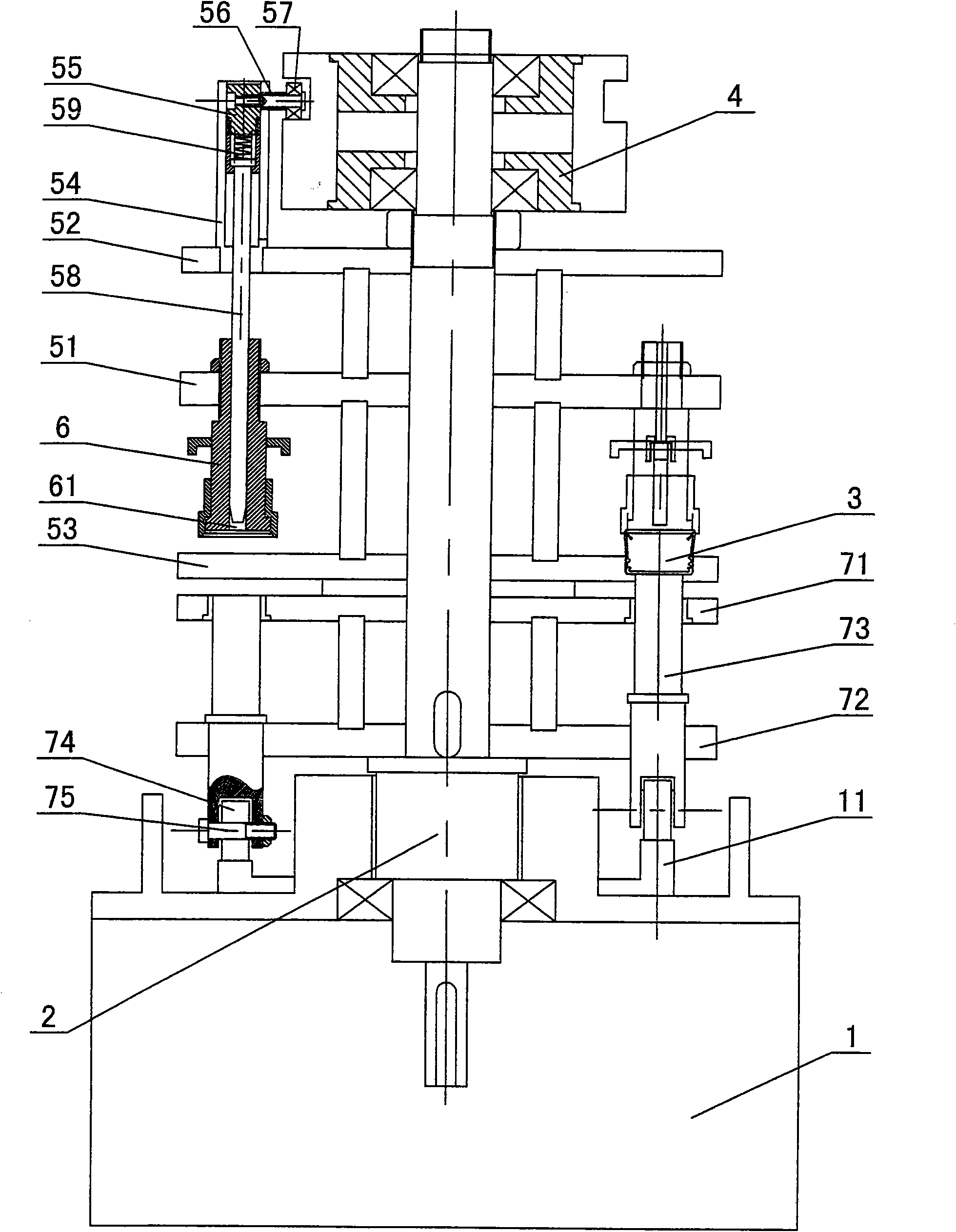

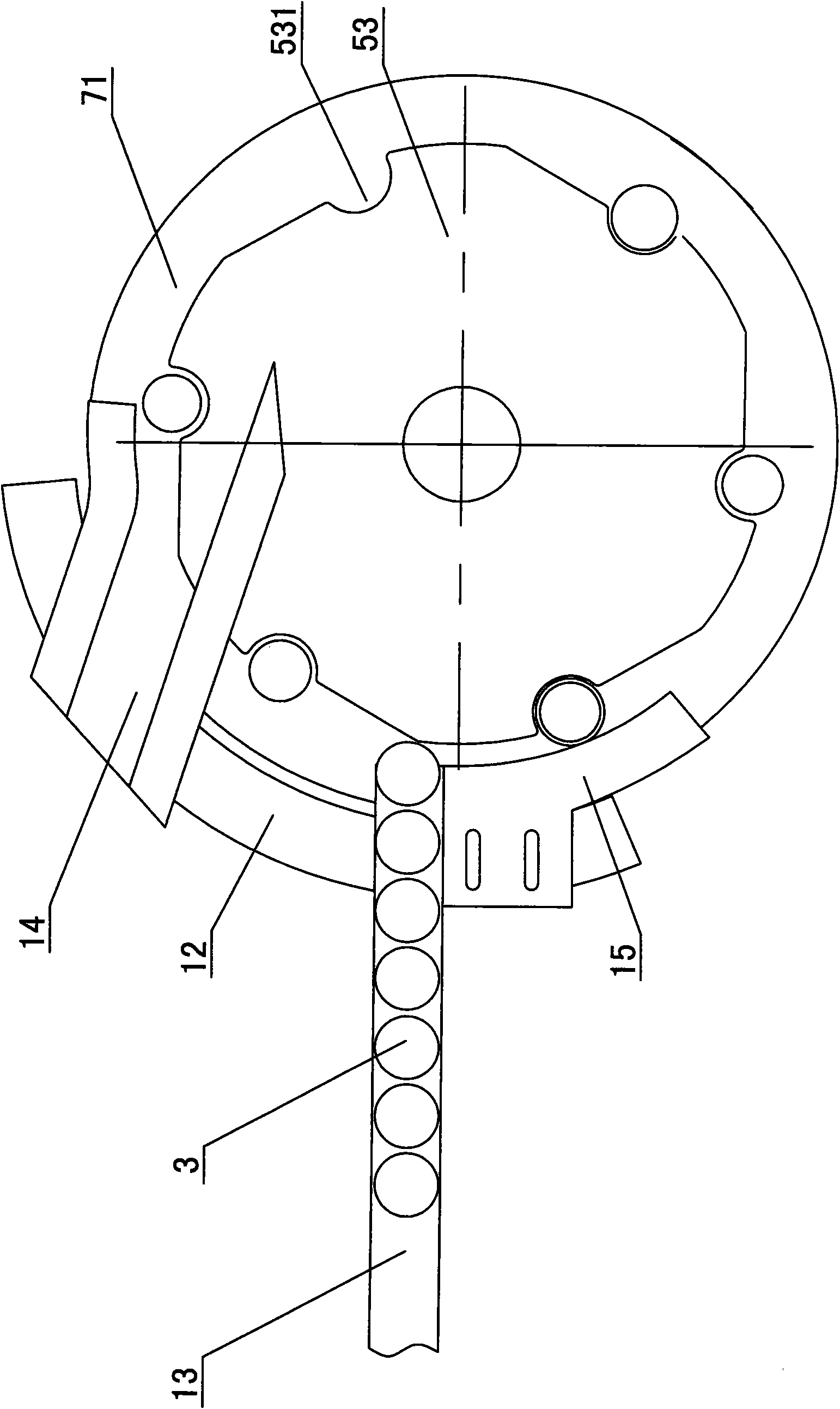

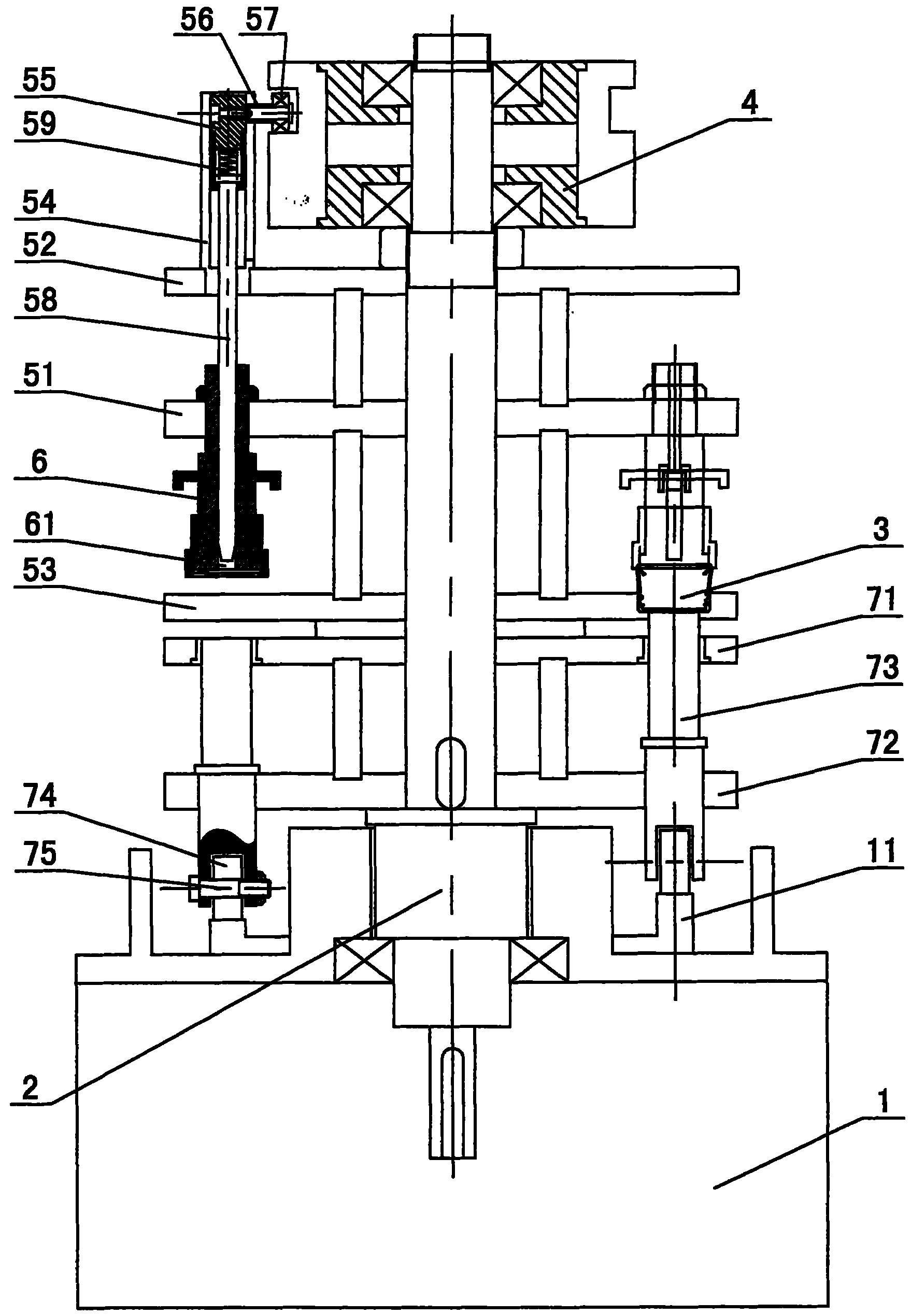

[0009] The present invention relates to bottle cap flanging processing equipment, such as Figure 1-Figure 2 Shown, it is characterized in that comprising frame 1, main shaft 2, slide rail 11 and support frame 12 are installed on the frame, slideway 13 and discharge opening 14 are installed on support frame, upper mold assembly, upper mold assembly, Lower die assembly and cam 4, upper die assembly includes upper template 51, upper fixed plate 52 and dial 53, have draw-in groove 531 in dial, draw-in groove matches with the bottle cap 3 that slideway falls, in The upper die head 6 is fixed in the upper die head 51, the upper die head has a perforation 61, a support sleeve 54 is installed on the upper fixed plate 52, an eccentric wheel 55 is installed in the support sleeve 54, a rotating shaft 56 is installed in the eccentric wheel, and a rotating shaft is installed outside the rotating shaft. Bearing 57, bearing is matched with cam 4, and cap-removing rod 58 is installed under e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com