Clamping and returning bending mechanism on automatic hoop bending machine for steel bars

A technology of bending mechanism and clamping mechanism, applied in the field of clamping and returning bending mechanism, can solve the problems of inability to bend quickly, not fully meet the needs of production, and inability to bend steel bars, and achieve flexible action, simple structure and strong adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

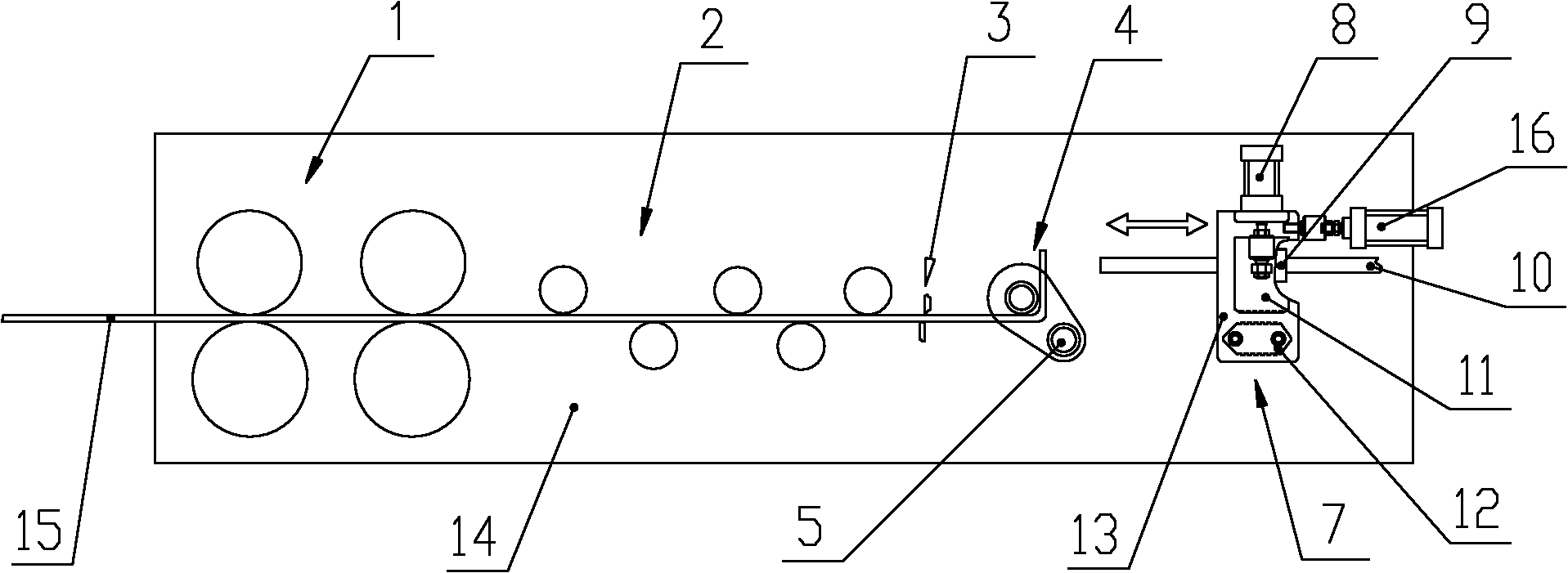

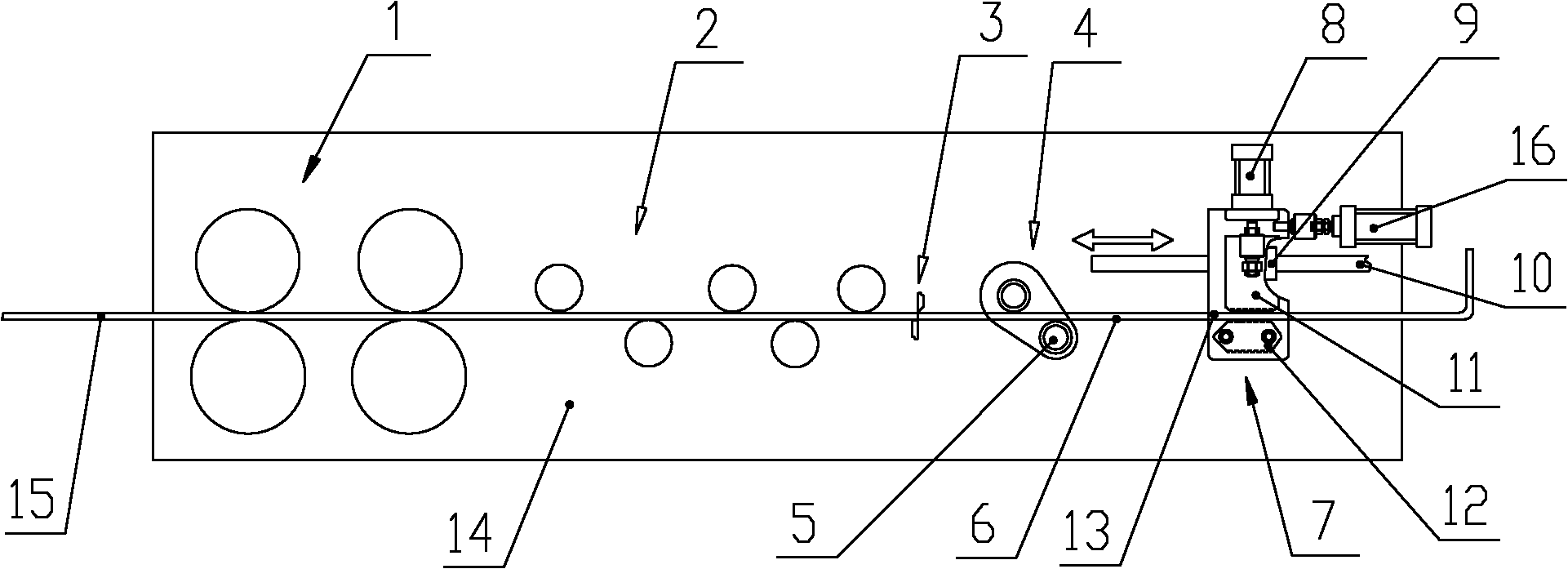

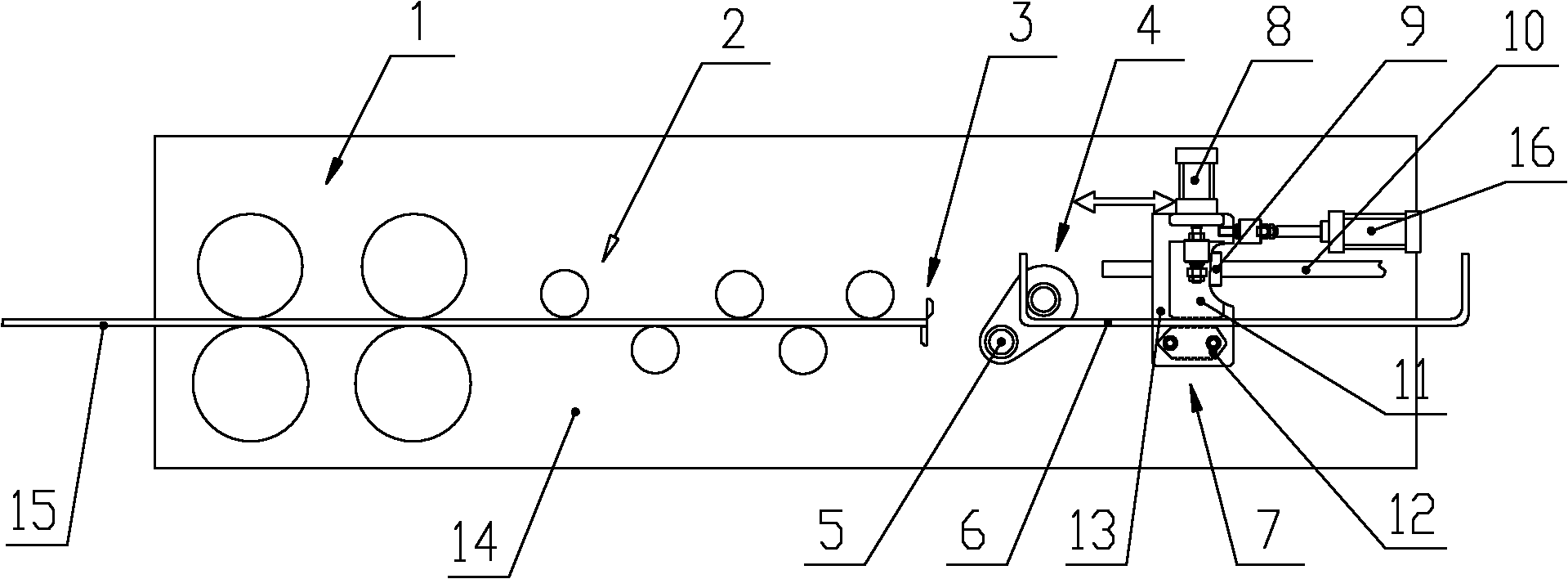

[0020] figure 1 It is a schematic diagram of the connection structure arranged on the automatic hoop bending machine of the present invention and a schematic diagram of the bending mechanism of the bending mechanism located on one side of the present invention: figure 2 yes figure 1 After the middle steel bar is bent by the bending mechanism, the movable clamping block of the present invention moves up, and after the steel bar continues to move forward, it is clamped by the clamping mechanism of the present invention to return the steel bar, and the shearing mechanism cuts off the steel bar schematic diagram: image 3 yes figure 2 In the present invention, after the steel bar is clamped, the steel bar is moved back, and the other end of the steel bar is bent by the bending mechanism; Figure 4 yes image 3 top view of Figure 5 yes image 3 Enlar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com