Switch and method for manufacturing the same

A switch and substrate technology, applied in the direction of electrical switches, contacts, electrical components, etc., can solve the problems of complicated processing, rising cost, and complicated composition of movable contact springs, and achieve a simplified structure, simple manufacturing, and improved assembly workability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

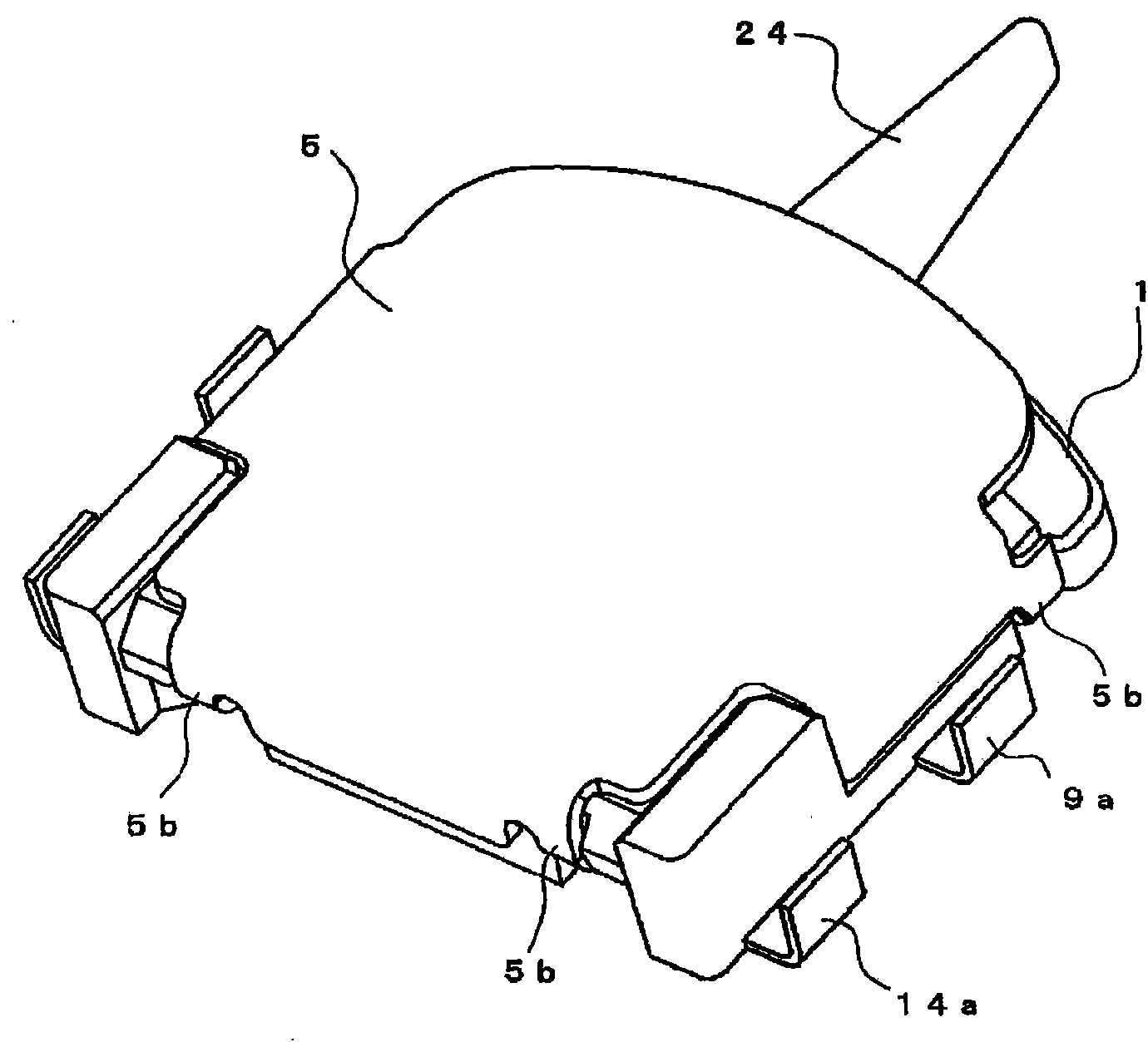

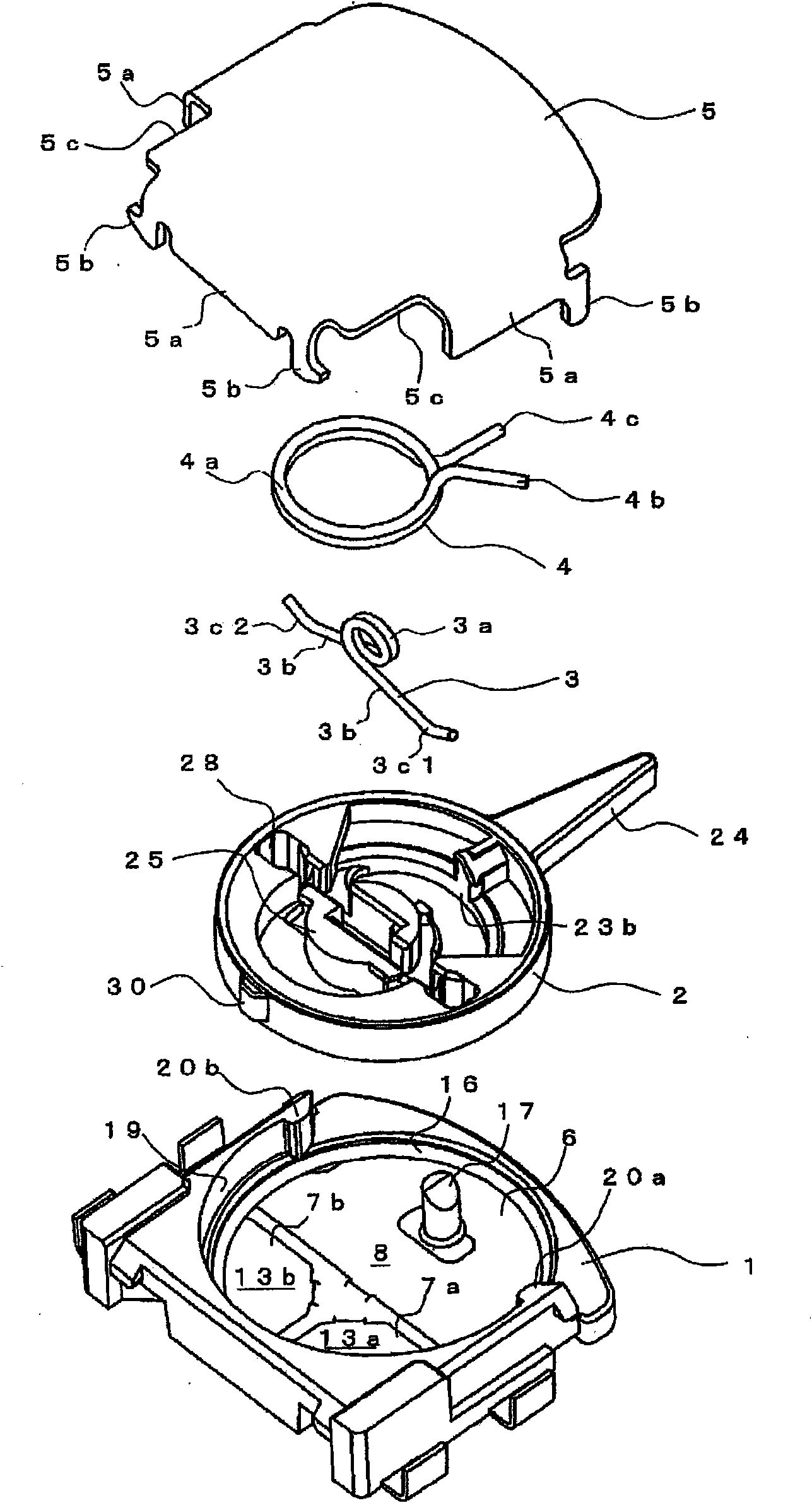

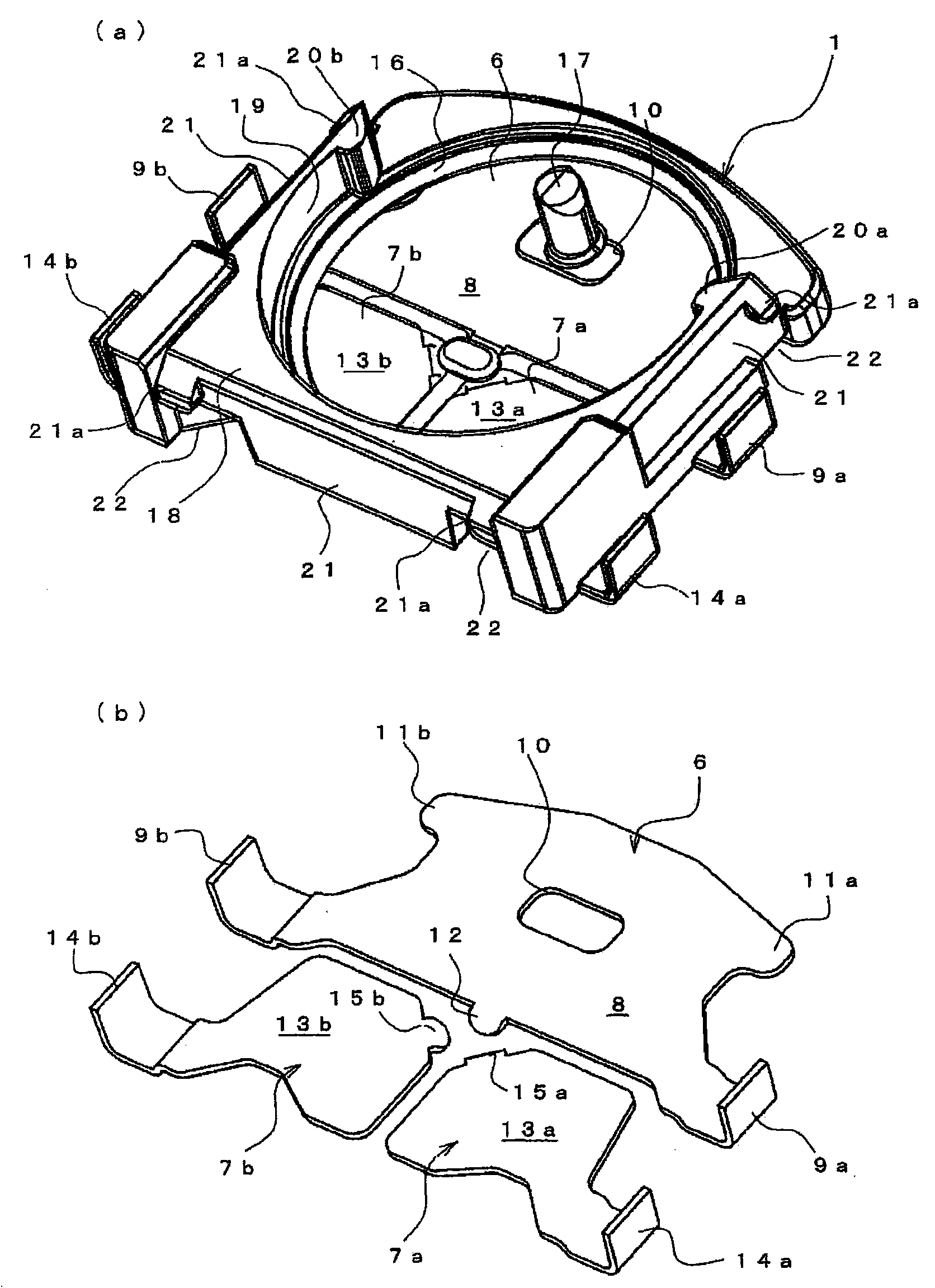

Image

Examples

other Embodiment approach

[0164] The present invention is not limited to the configurations described in the above-mentioned embodiments, and various changes can be made.

[0165] For example, in Figure 7 ~ Figure 9 Among them, the difference from the above-mentioned embodiment is the configuration of the movable contact spring 3 (the configuration of other parts is substantially the same).

[0166] That is, in the above-described embodiment, the position where the arm portions 3b, 3b at both ends protrude from the winding portion 3a is the lower side, that is, the base body 1 side. Figure 7 Among them, the difference is on the cover body 5 side.

[0167] In addition, in Figure 8 Among them, the elastic pressing portion is not constituted by the winding portion 3a, but is constituted by the bent portion 31 bent upward, that is, toward the side of the cover body 5, and the long hole 28 of the operation rod 2 for accommodating the movable contact spring 3 is formed straightly. different. According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com