Electrically driven equipment with control function of brushless direct current motor

A brushed DC motor and control function technology, which is applied in the direction of connection with control/drive circuits, electric components, electrical components, etc., to reduce costs, eliminate power loss, and simplify equipment installation and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are used to illustrate the present invention, but are not intended to limit the protection scope of the present invention.

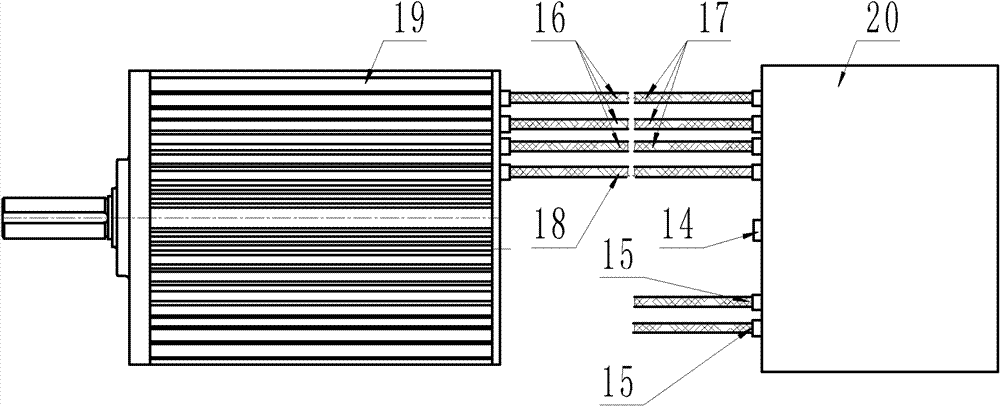

[0025] Such as figure 2 Shown is the structure of a brushless DC motor electric drive device with control function according to the present invention.

[0026] This is an air-cooled permanent magnet brushless DC motor drive device with control function, which is used as a drive device for pure electric vehicles. The motor stator assembly 2 is connected with the air-cooled housing assembly 1 with cooling fins by press fit. The bearing 4 is fixed in the motor front end cover 5 and the motor rear end cover 6, the two ends of the motor rotor assembly 3 with the Hall position sensor are supported by the bearing 4, the motor front end cover 5 and the motor rear end cover 6 use fasteners 7 It is connected with the housing assembly 1 to form a complete brushless DC motor component.

[0027] Such as figure 2 In the shown exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com