Liquid crystal display (LCD) test fixture and test method thereof

A technology for LCD screens and test fixtures, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor control of pressing force, complex structure of test fixtures, incomplete contact, etc., to avoid LCD screen damage, Test the effect of convenient and reliable, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

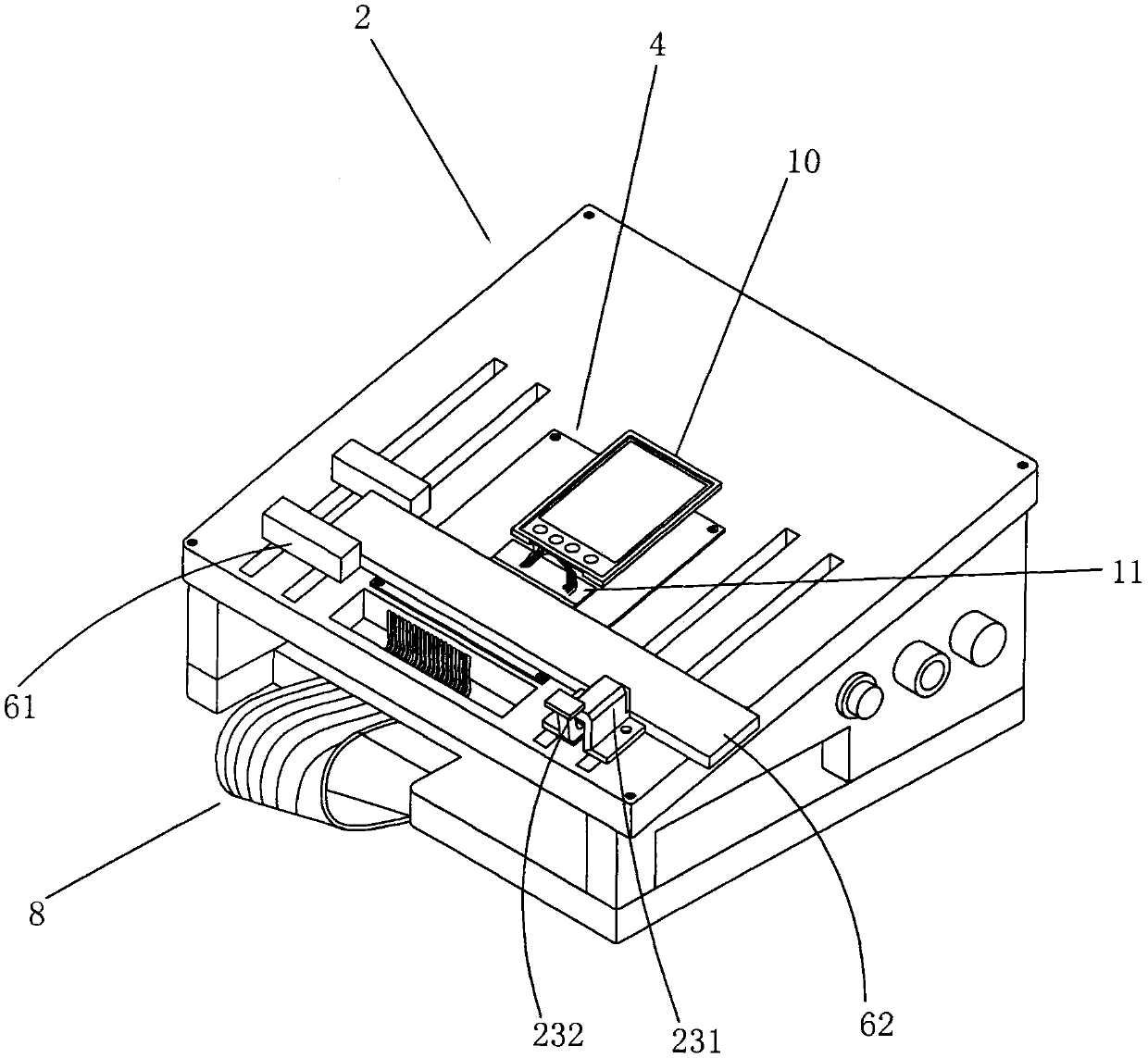

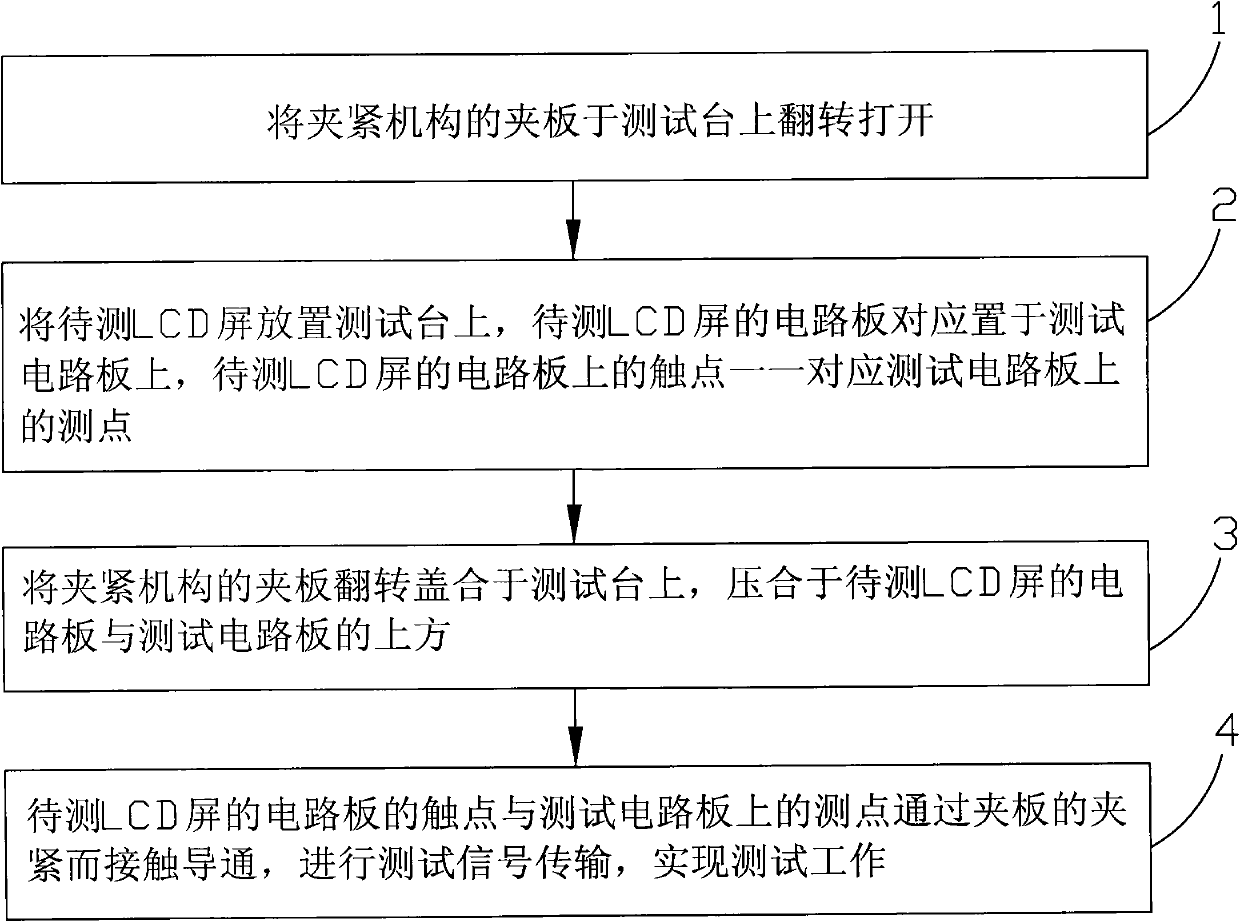

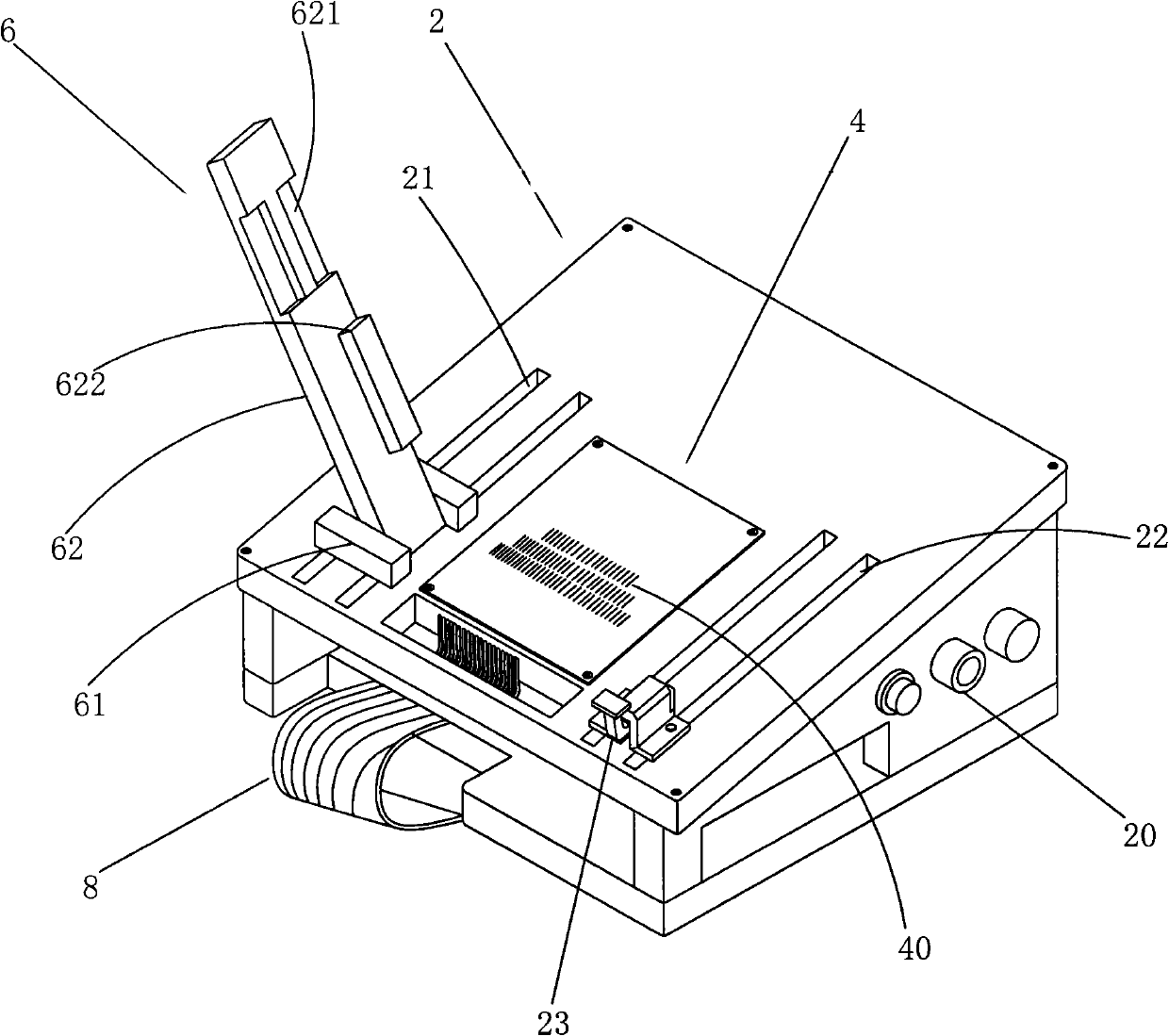

[0025] Such as Figure 1-2 As shown, the LCD screen test fixture of the present invention includes: a test bench 2, a test circuit board 4 placed on the test bench 2, a clamping mechanism 6 rotatably mounted on the test bench 2, and during the test, by turning over the clamp The tightening mechanism realizes the electrical connection test by clamping the LCD screen 10 to be tested and the test circuit board 4 .

[0026] The test platform 2 is also provided with an accommodating slot (not marked) corresponding to the test circuit board 4 , and the test circuit board 4 is positioned and accommodated in the accommodating slot. A connector (not shown) is provided inside the test bench 2 , which is electrically connected to the test circuit board 4 through a cable 8 , and the connector is further connected to a power supply through a power jack 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com