Method for detecting effective heat dissipation of encapsulation structure of semiconductor light-emitting diode (LED)

A technology of light-emitting diodes and packaging structures, which is applied in the testing of machine/structural components, measuring devices, optical instrument testing, etc., to achieve the effect of high speed and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

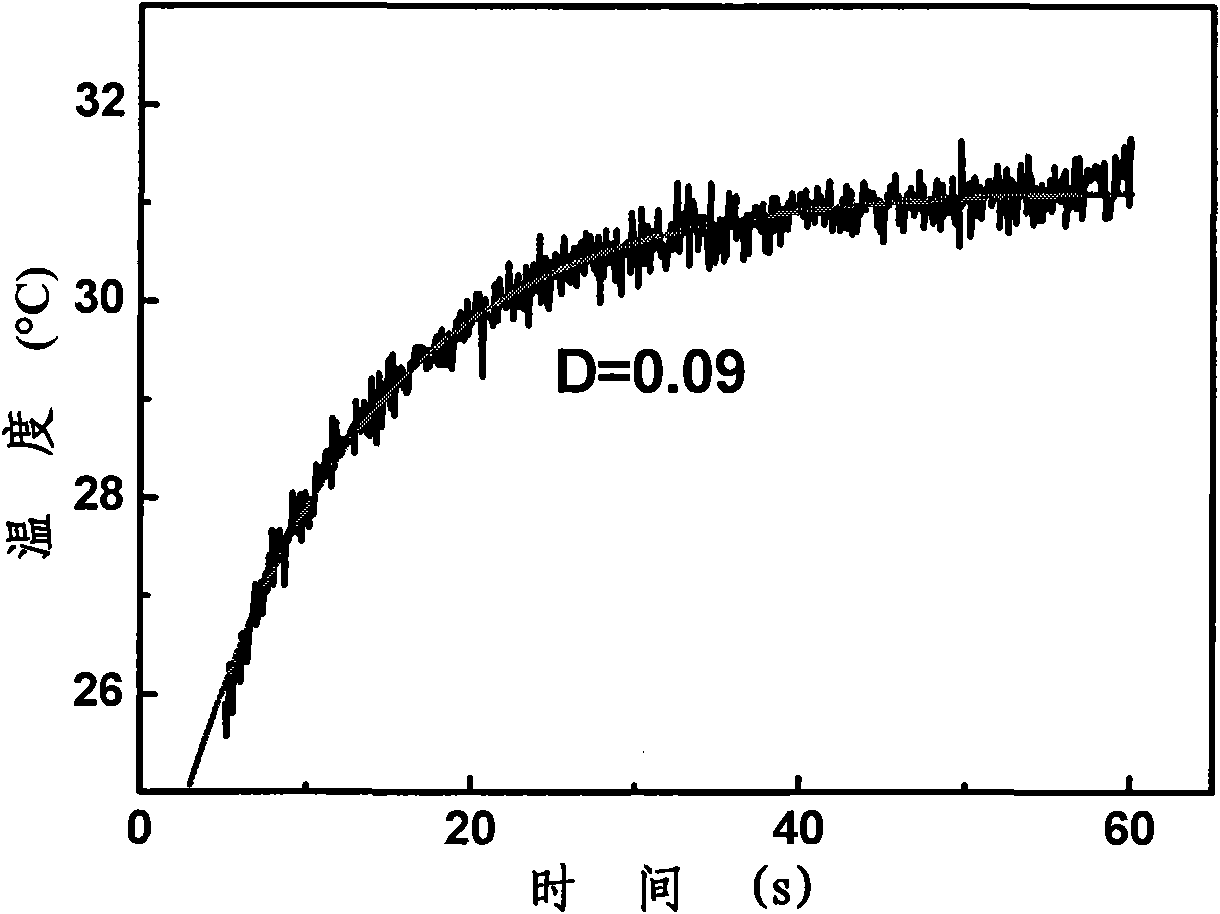

Embodiment 1

[0020] The LED lamp packaged by more than 100 LED chips is the test object, which is called lamp 1. The specific measurement steps are as follows:

[0021] Concrete steps of the present invention are as follows:

[0022] 1. Use a constant current power supply with pulse function and DC output function, connect it to lamp 1, and put the power supply in pulse power supply mode. The pulse power supply function is that the pulse width is 5 microseconds, the pulse period is 1 second, and the pulse current amplitude The DC current value is 0.5 ampere, which is the same as that of the lamp in normal operation, so as to ensure that the junction temperature of the light-emitting diode in the lamp will not change, and at the same time ensure that the light-emitting spectrum of the light-emitting diode under pulse driving is consistent with the spectral characteristics under normal working conditions. Connect the incident slit of a small visible light spectrometer with a spectral resolut...

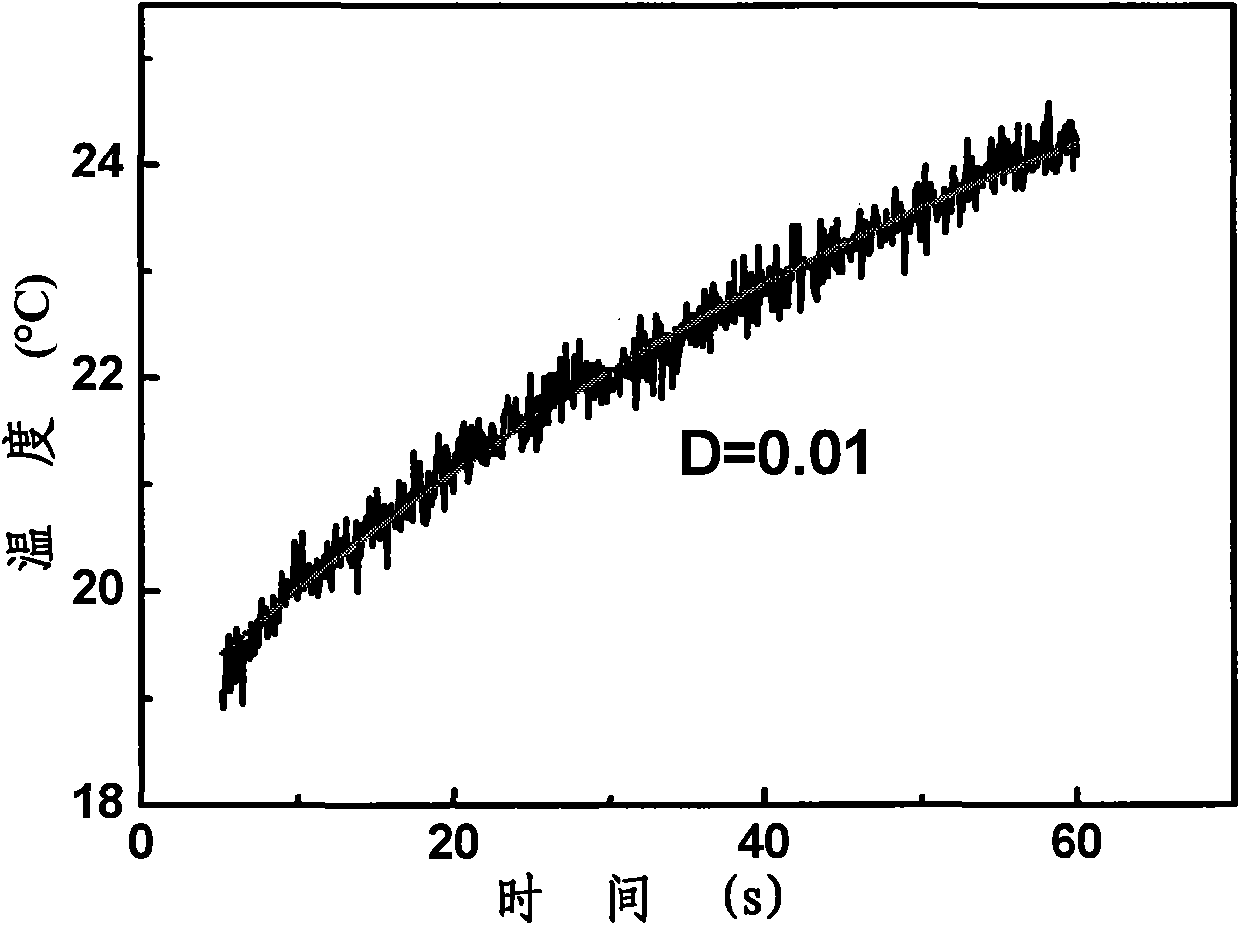

Embodiment 2

[0028] An LED lamp packaged with more than 300 LED chips identical to those used in lamp 1 is the test object, which is called lamp 2. The specific measurement steps are exactly the same as in Example 1, and the final effective heat dissipation coefficient of the package structure of lamp 2 is obtained. The D value is 0.01. With this D value, the quality index of heat dissipation of lamp 2 is smaller than that of lamp 1. Therefore, it can be considered that the package heat dissipation effect of lamp 1 is obviously better than that of lamp 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com