Ventilation test device of crankcase

A technology for crankcase ventilation and test device, which is applied to measurement device, aerodynamic test, engine test and other directions, can solve the problems of high cost, high test cycle and cost, long production cycle of rapid prototyping parts, etc., and saves money The effect of cycle time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

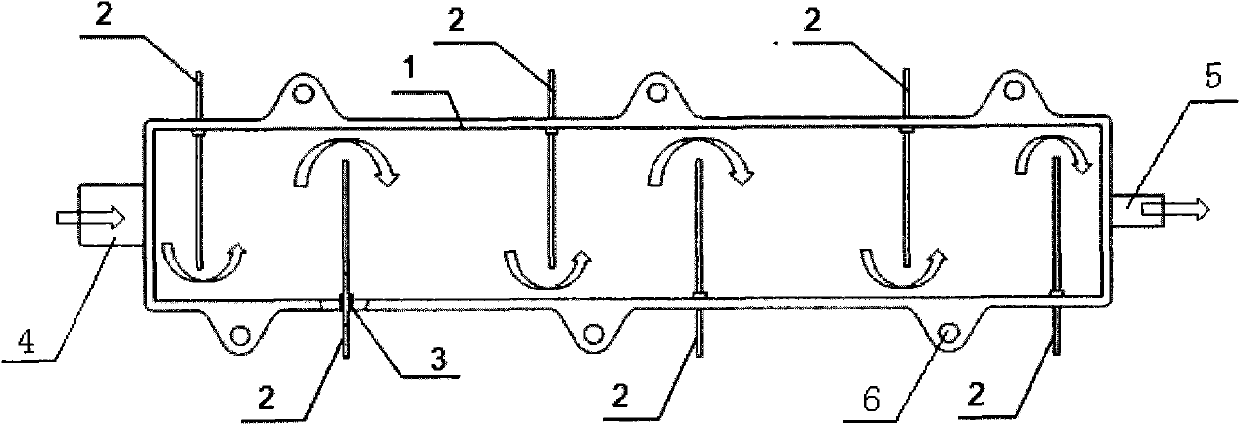

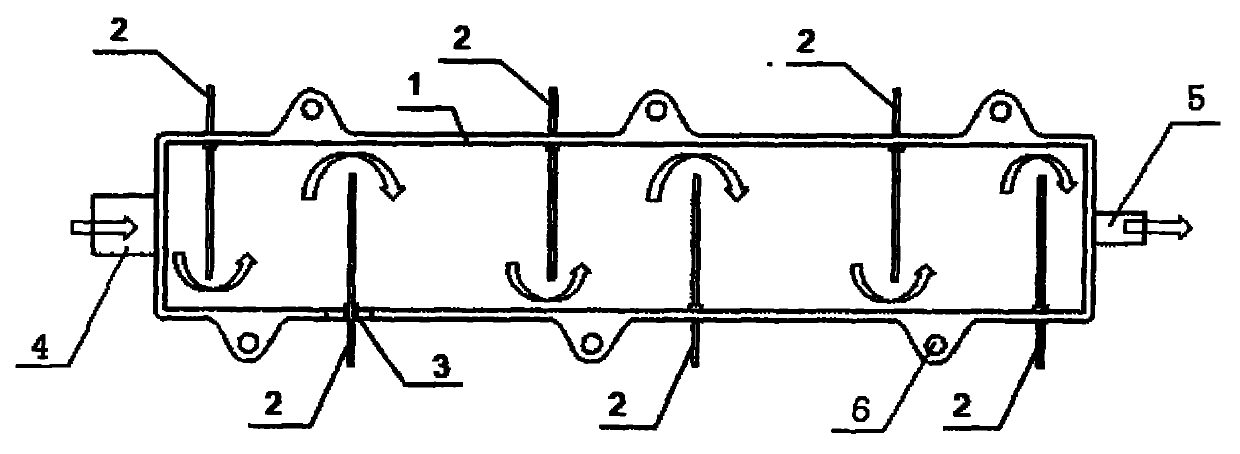

[0018] Such as figure 1 As shown, the crankcase ventilation test device of the present embodiment comprises a frame-type body 1 formed by connecting four surrounding plates, the opposite ends of the body 1 are respectively provided with an air inlet 4 and an air outlet 5, and the sides of the body 1 both sides A plurality of staggered slide plates 2 are movably installed on the wall, and a sealing ring 3 made of rubber is installed between the body 1 and the slide plates 2 .

[0019] Scales are engraved on the skateboard 2, which is convenient for adjusting and recording the position of the skateboard 2.

[0020] The side wall of the main body 1 is provided with bolt holes 6 for fixing, so as to fix the main body 1 on the valve chamber cover.

[0021] The test method of the above-mentioned crankcase ventilation test device comprises the following steps:

[0022] A: Connect the crankcase ventilation test device and the valve chamber cover used for the test through flanges, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com