Test positioning clamp for auxiliary spray nozzle of air-jet loom

A technology for assisting nozzles and positioning fixtures, which is applied in the direction of measuring devices, supporting machines, mechanical equipment, etc., can solve problems such as difficulties in the inspection process, achieve simple structure, improve test efficiency, and be easy to popularize and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

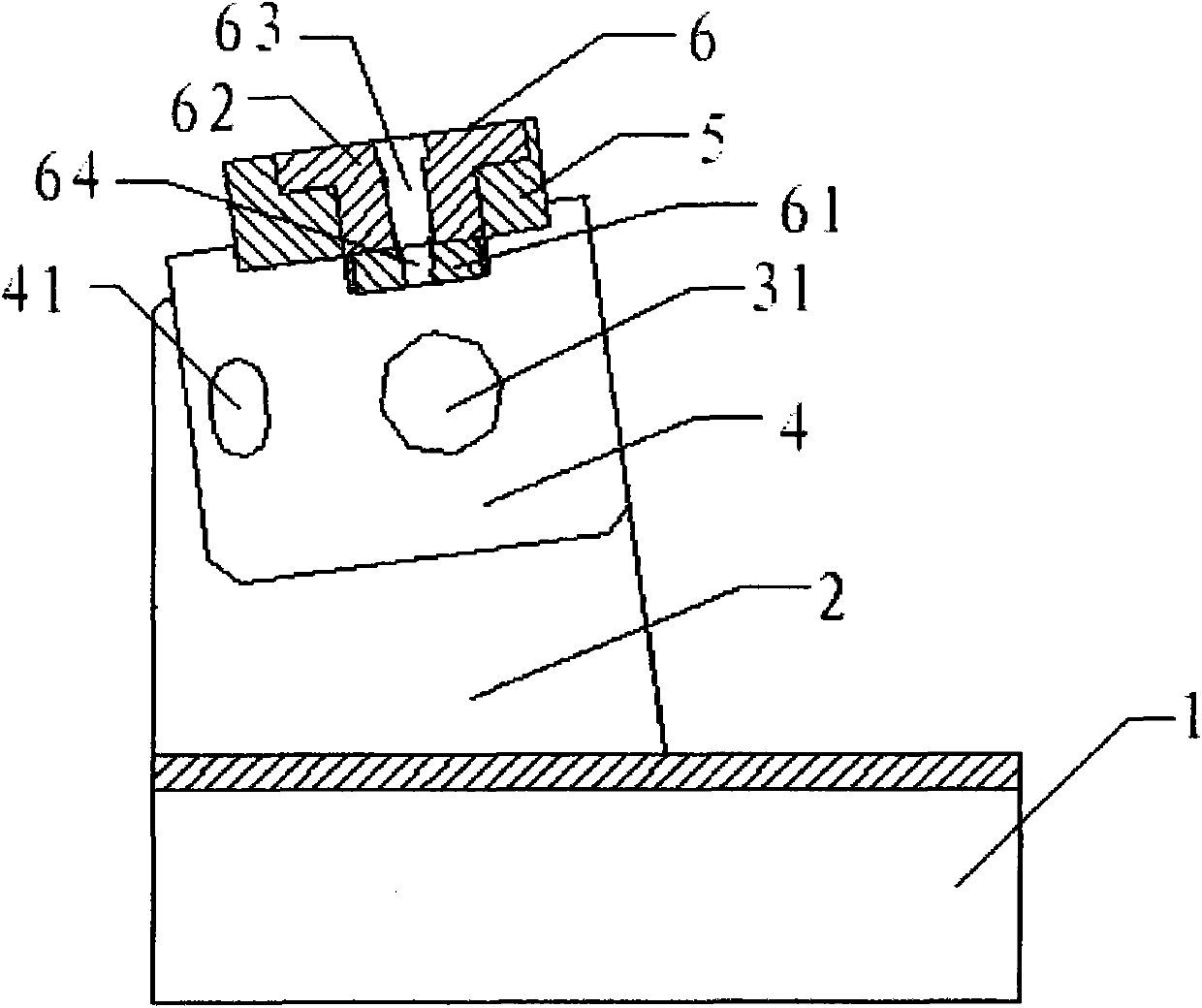

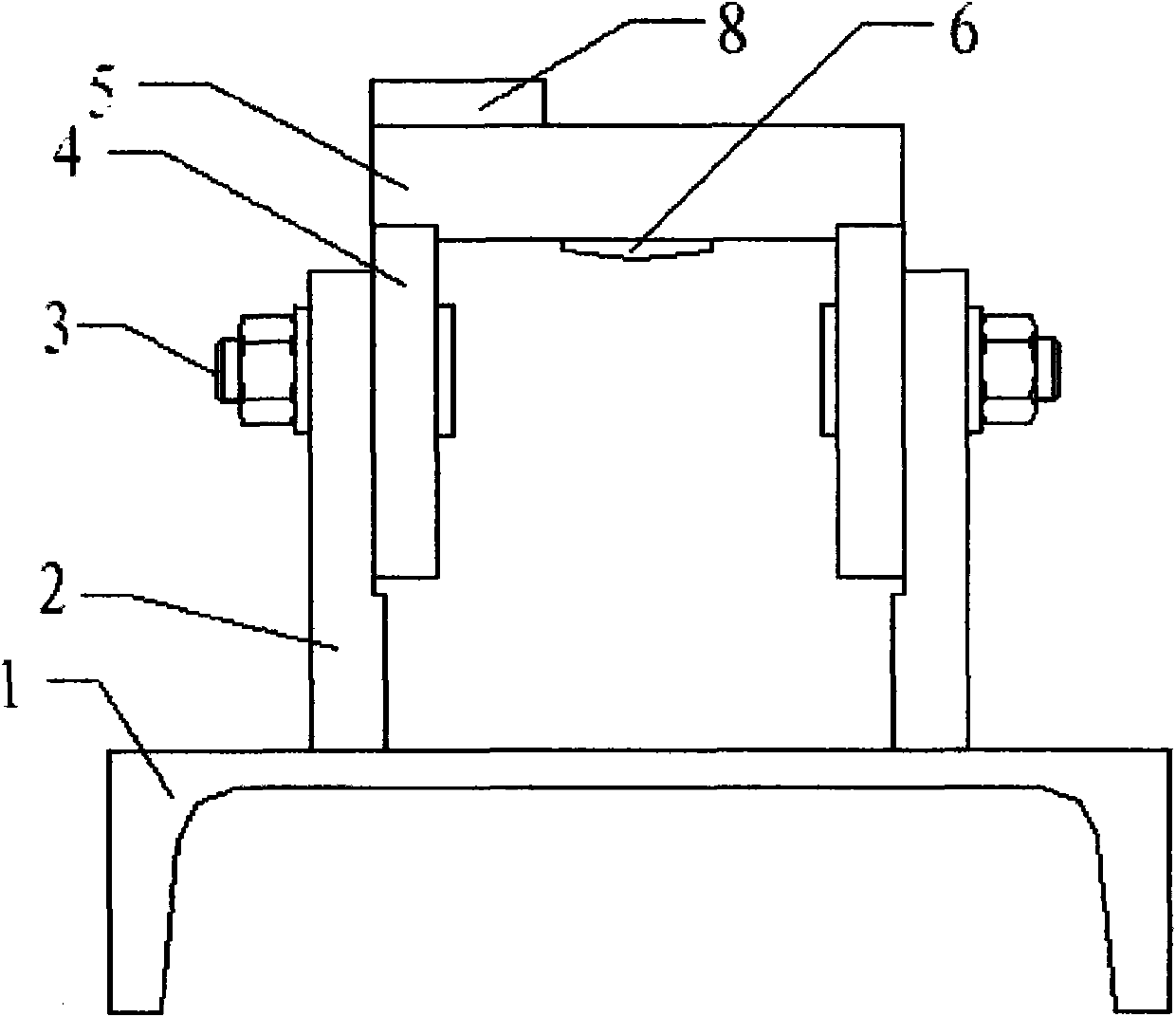

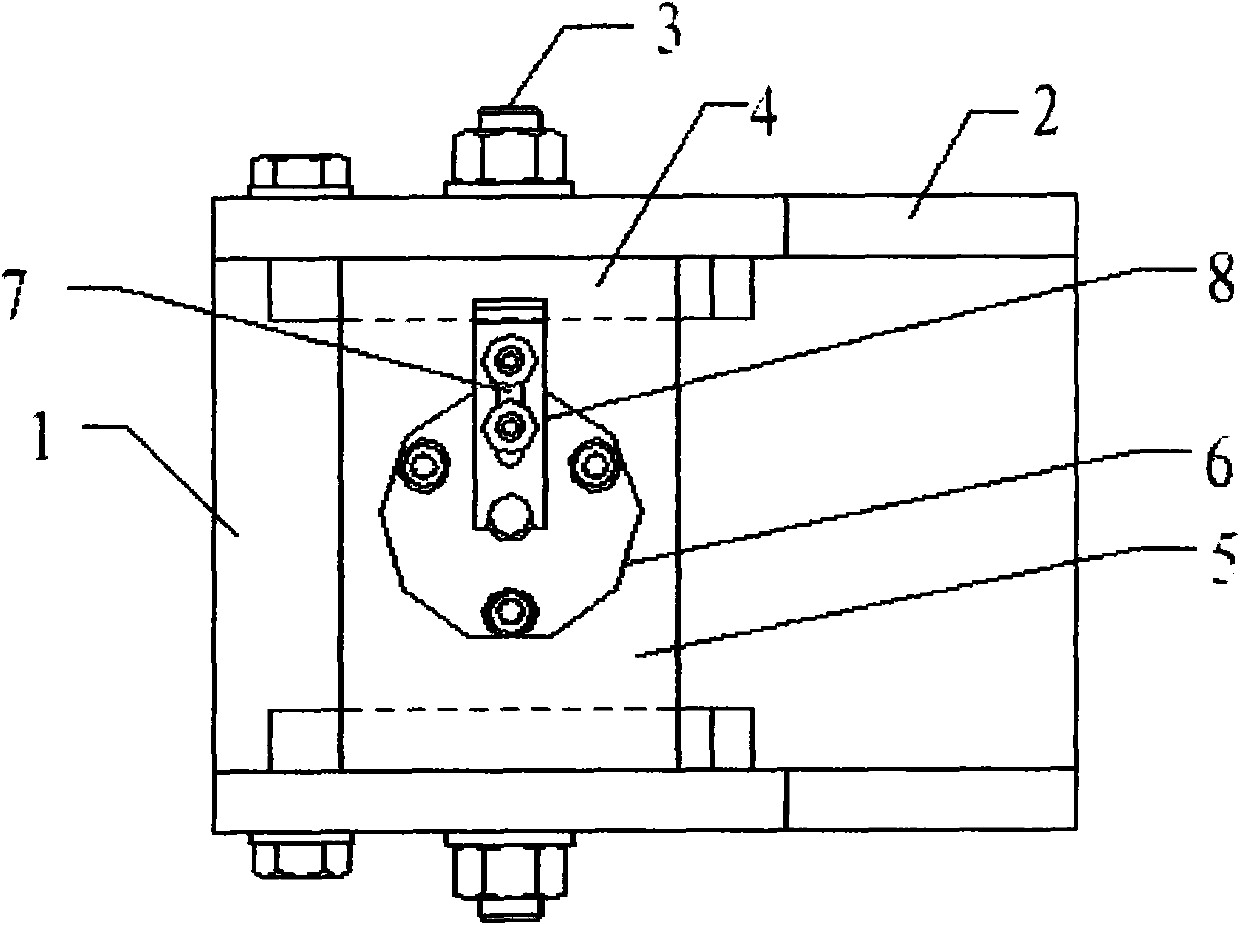

[0021] see Figure 1 to Figure 5 Shown, a kind of air-jet loom auxiliary nozzle test positioning fixture, it comprises a fixture base 1, and described fixture base 1 is provided with a pair of support 2, and described support 2 is provided with an angle adjustment block 4, and described angle adjustment block 4 can be rotated on the bracket 2, the angle adjustment block 4 is provided with a positioning block 5, the positioning block 5 is provided with an auxiliary nozzle positioning assembly 6, and the auxiliary nozzle positioning assembly 6 includes a central positioning block 61 And the circumferential positioning block 62, the central positioning block 61 has a cylindrical hole 63, the circumferential positioning block 62 has a first waist hole 64, the cylindrical hole 63 and the first waist hole 64 coaxial, and a guide groove 7 is formed on the end surface of the auxiliary nozzle positioning assembly 6, and a vertical positioning platen 8 is installed in the guide groove 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com