Oil supply mechanism of curved needle seat in sewing machine

A sewing machine and looper technology, applied to sewing machine components, sewing equipment, textiles and papermaking, etc., can solve problems such as inability to supply looper needles and cumbersome processing procedures, and achieve the effects of simplified structure, convenient processing, and guaranteed oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

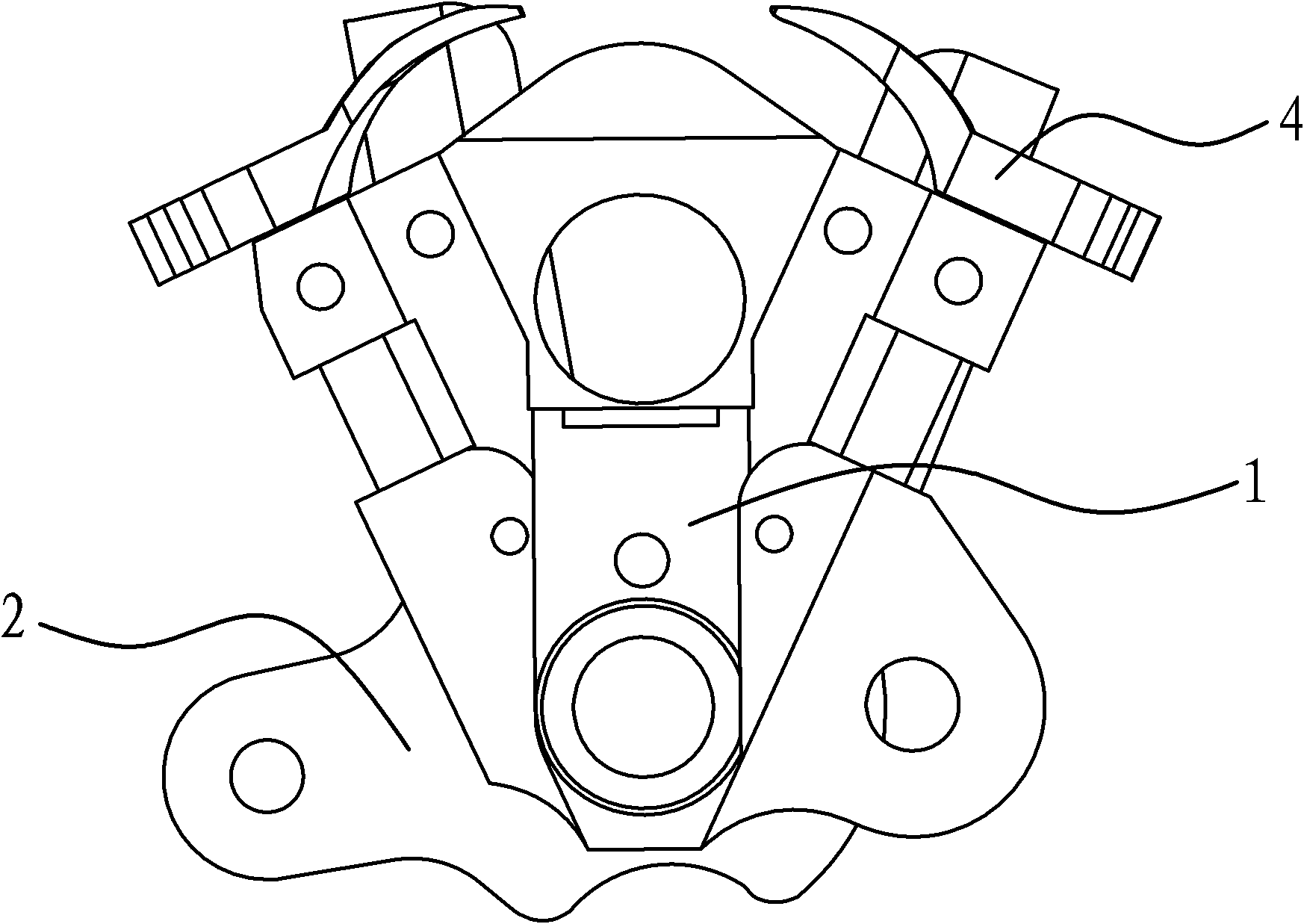

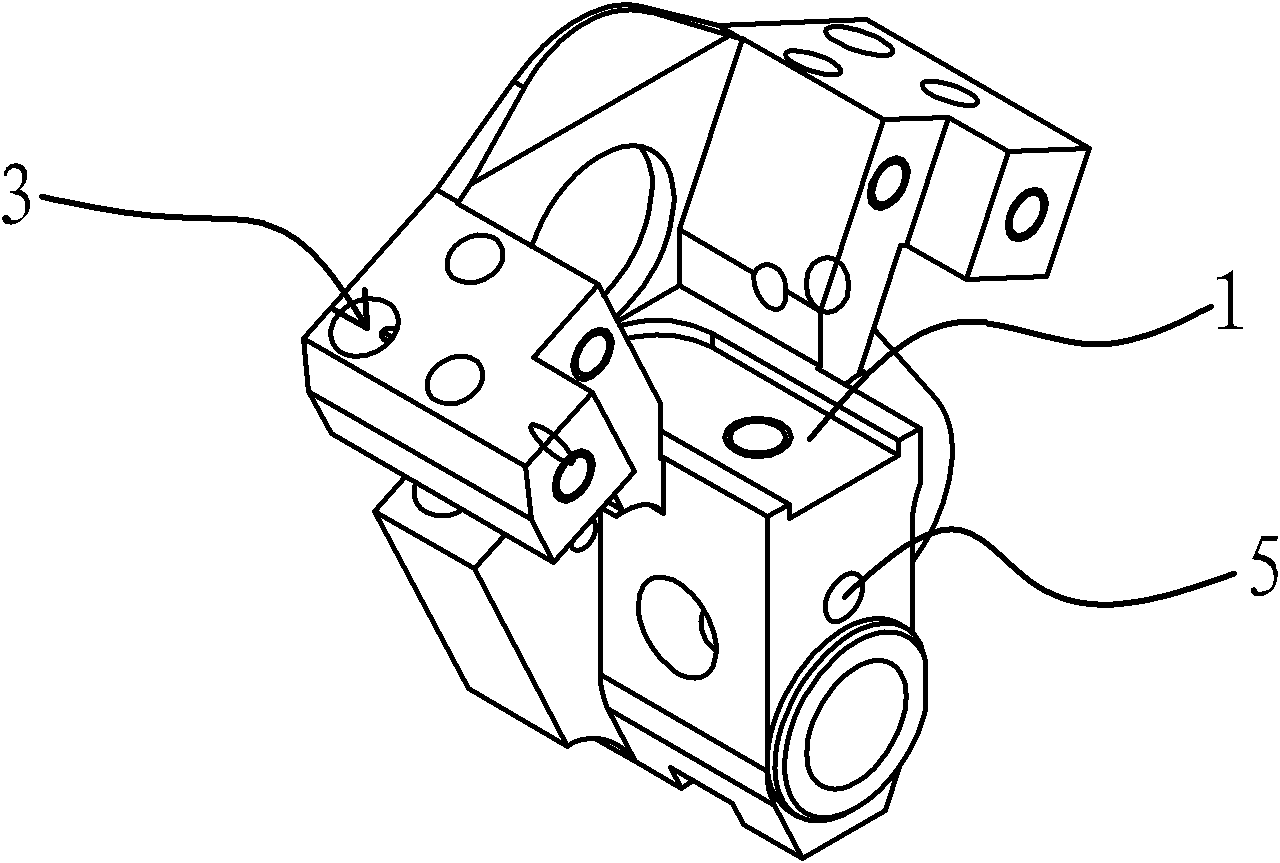

[0020] The oil supply mechanism at the looper seat in this sewing machine is applied to the keyhole sewing machine. The keyhole sewing machine includes the up and down movement mechanism of the needle bar, the needle swing mechanism and the thread take-up mechanism, the looper 4 on the looper seat and the actuating cam plate 2 Synchronized with the up and down movement of the sewing needle. During the movement, the support table 1 and the actuating cam plate 2 frequently move toward each other, which is prone to faults such as sintering; meanwhile, the looper 4 also needs a certain amount of lubrication. The mechanism can provide lubrication to the contact surface of the support platform 1 and the actuating cam plate 2 and the looper 4, and the oil guide structure is reasonably set, which is convenient for production and processing.

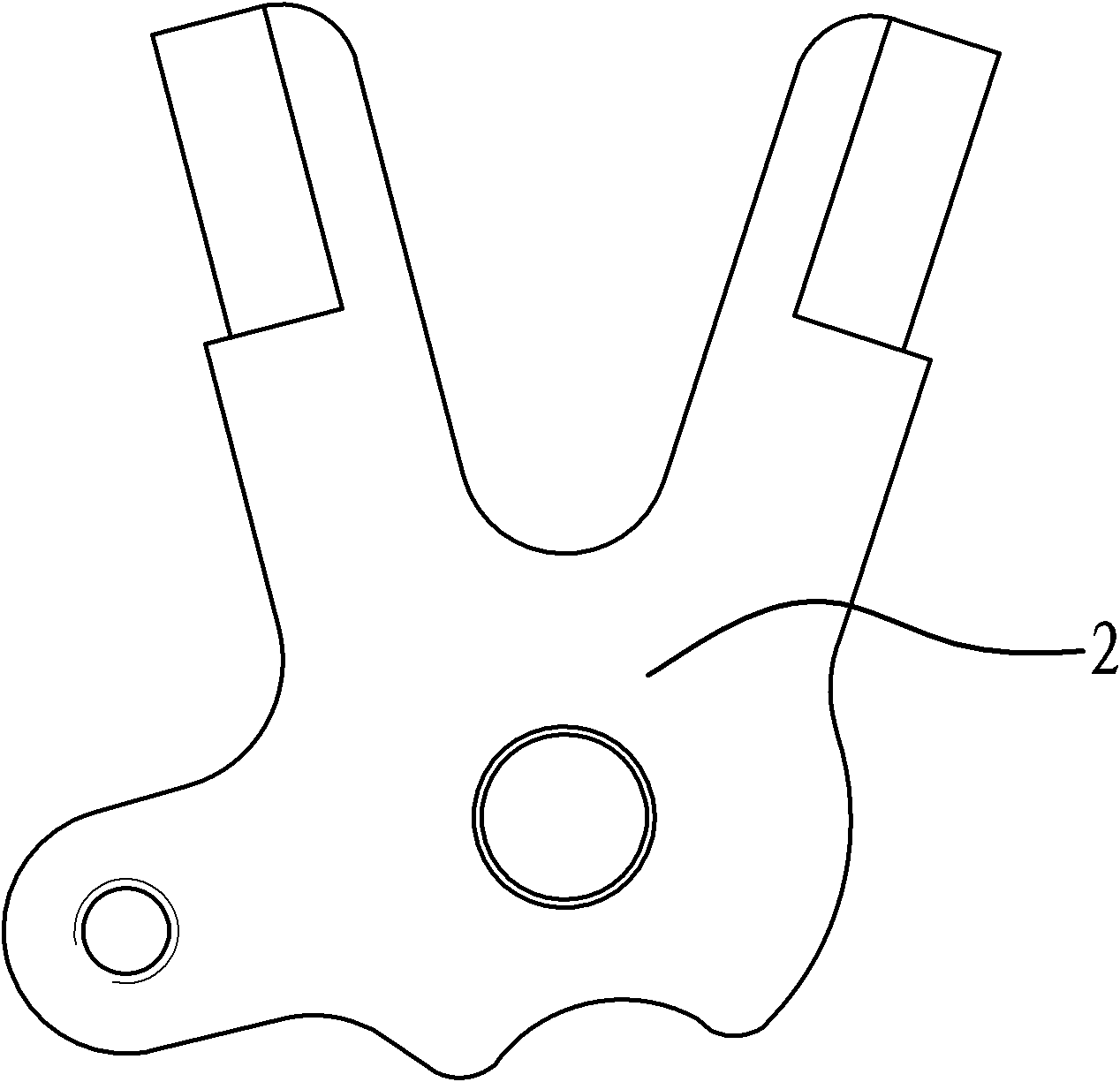

[0021] Such as figure 1 , figure 2 with image 3 As shown, the looper seat of the sewing machine includes a support platform 1 and a V-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com