N-shaped underground plug-flow methane fermentation system

A biogas fermentation and plug-flow technology, which is applied in the direction of gas production bioreactors, biological sludge treatment, waste fuel, etc., can solve the problems of high cost, blocked gas production, and reduced cultivated land area, so as to save labor and increase gas production. High, easy to manage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

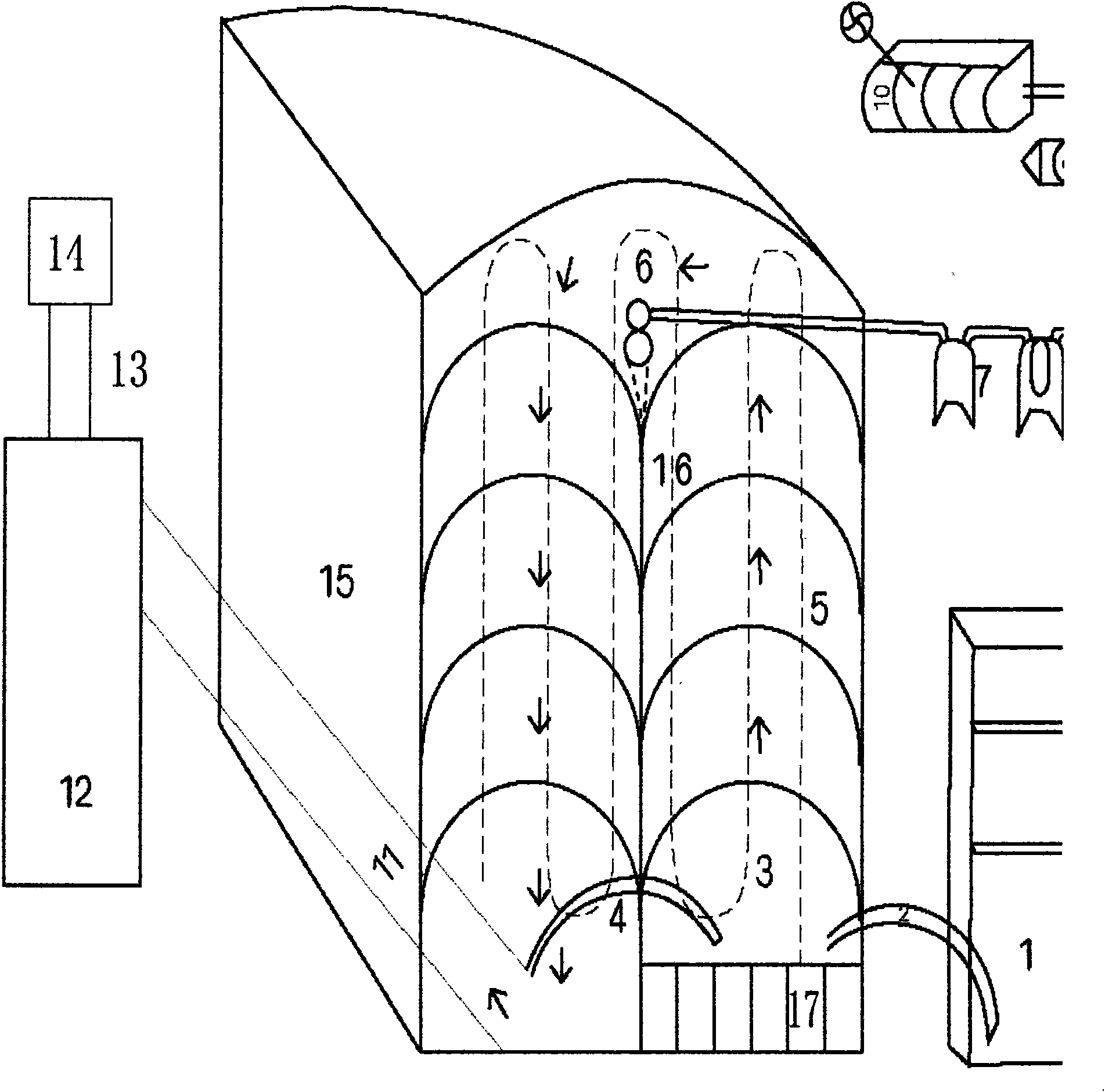

[0012] Add an appropriate amount of biogas slurry and biogas residue to 1 (raw material pretreatment pond), stir and ferment into the biogas digester to produce gas in time, start 2 (motor feeder) to feed in time without manual feeding, 3 heating pipes, in cold weather Heating and increasing the temperature of the biogas digester from time to time to ensure the gas production rate, 4 motorized strong reflux devices, from the discharge room to the feed room, forcefully push the raw materials to move in the biogas digester, solve the problem of shell breaking, and increase the gas production rate of the biogas digester .5n-type biogas digesters are all buried underground, and a pigsty or cowshed can be built on the upper part of the biogas digester to make rational use of the above-ground area. The materials are all poured with sandstone cement, and the cost is the lowest. 6. The gas outlet pipe automatically sends the biogas to 7 for automatic dehydration. A switch is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com