Automatic sorting machine

An automatic sorting and sorting device technology, applied in the directions of transportation, packaging, storage devices, etc., can solve the problems of high stacking height of drugs, easy to damage drug packaging, not suitable for prescription volume, etc., to achieve compact structure, drug storage, etc. Or the effect of large storage volume and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

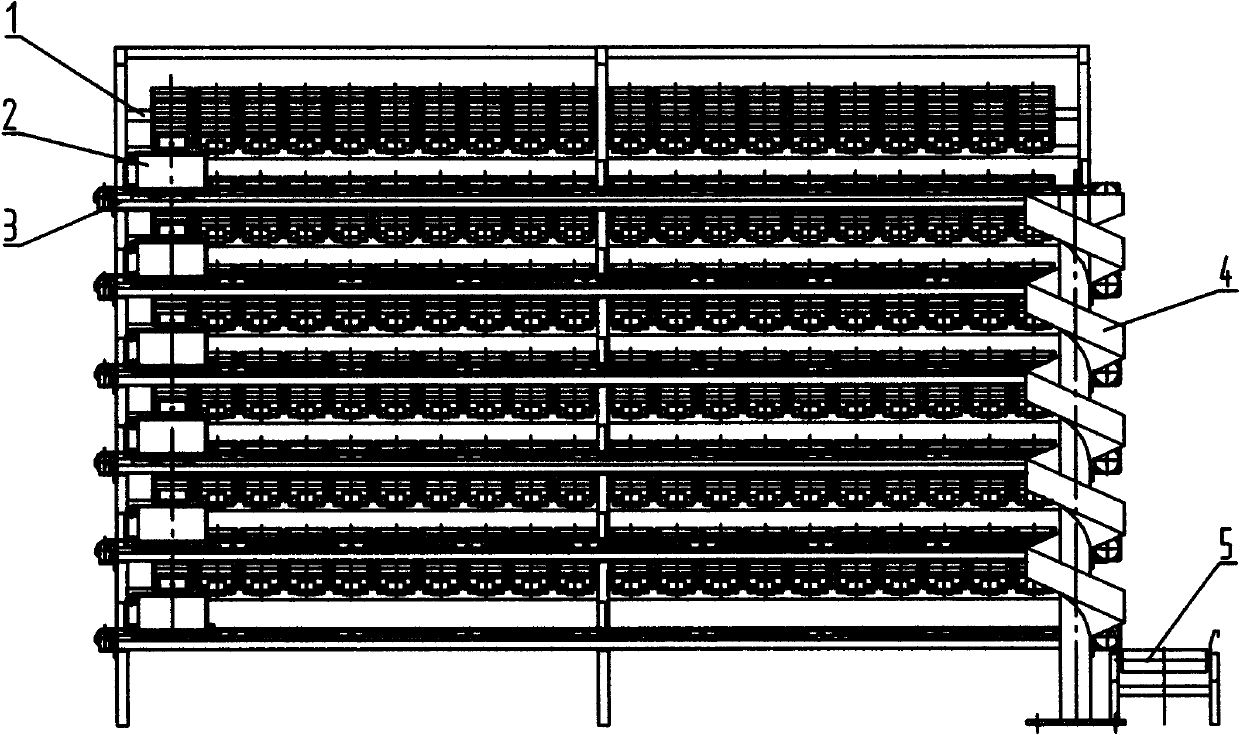

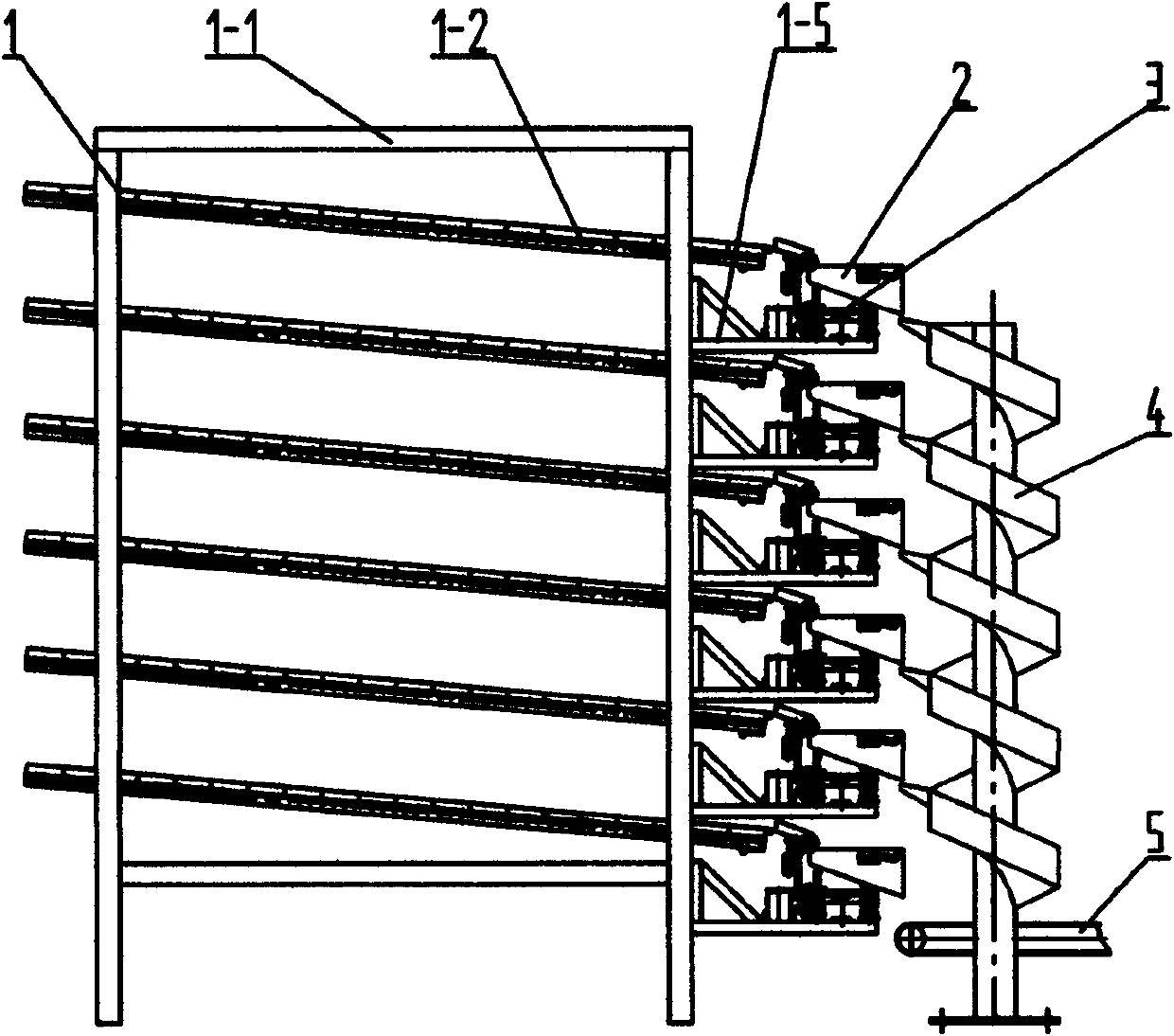

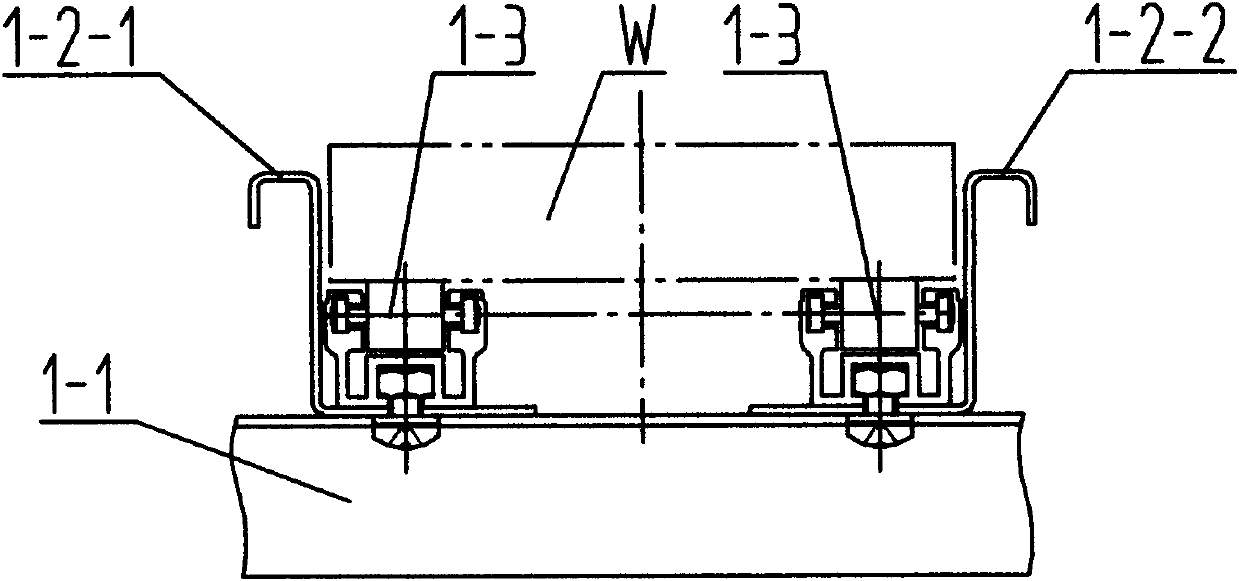

[0022] Attached below Figure 1-8 The implementation process of the present invention is described in detail.

[0023] When the present invention is used for automatic sorting of boxed medicines, the number of layers of medicine storage tanks and the number of rows of each layer of the fluent shelf can be determined according to factors such as the number of sorted medicines, the quantity of prescriptions, and the convenience of replenishment. The control of the shuttle sorting device on each layer in the shelf is realized through the PLC control system software compiled according to the requirements of the actual sorting operation process. The control system is connected with the upper computer system of the entire pharmacy sorting management through the computer bus. Work under the control instructions of the machine system.

[0024] For example, according to the sorting volume of boxed medicines in a certain pharmacy, it is determined to make a 20-row, 10-layer fluent shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com