Rock wool pleating machine and pleating method thereof

A pleating machine and rock wool technology, which is applied in the field of material processing, can solve the problems of restricting energy saving in buildings and industries, failing to meet the performance requirements of industrial thermal insulation rock wool products, and poor weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

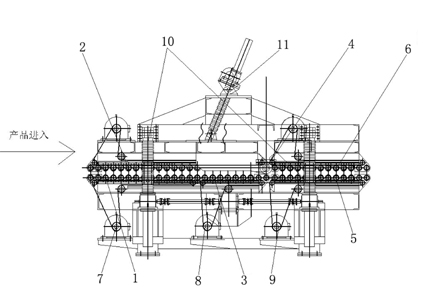

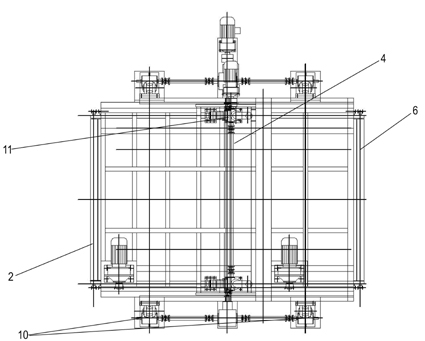

[0017] Example 1. pleating machines, such as Figure 1-3 shown.

[0018] The high-strength rock wool pleating machine described in this embodiment consists of three sets of upper and lower pressing rollers (1, 2 are the first set, 3, 4 are the second set, 5, 6 are the third set) and their driving devices ( 7, 8, 9), the spacing adjustment device 10 between the upper and lower pressure rollers and the tensioning device 11 of the upper pressure roller group of the first group. The first, second and third sets of pressing rollers are connected front and back, and are independently driven by three driving devices 7, 8, and 9, so as to independently control the running speed of each pressing roller set. The pressure roller spacing device 10 is used to adjust the distance between the upper and lower pressure rollers to control the thickness of rock wool products; a set of upper pressure roller tensioning devices 11 is used to adjust and control the opening angle of the first set o...

Embodiment 2

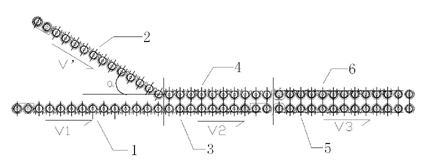

[0019] Example 2. Pleating method

[0020] The rock wool fibers sprayed with adhesive on the surface are spread into a multi-layer rock wool layer with uniform density through the pendulum machine and sent to the pleating machine. The transmission speed V1 of the roller is 15.6m / min, the transmission speed V' of the upper pressing roller is V1 / cos55°=27.2m / min, the transmission speed V2 of the second group of upper and lower pressing rollers is 9m / min, and the third group of upper and lower pressing rollers Transmission speed V3 is 5.2m / min. The first pleat is generated by the difference V1-V2 between the first set and the second set of pressure rollers, and the second pleat is produced by the difference V2-V3 between the second set and the third set of pressure rollers. After the second pleating, the rock wool fiber has a three-dimensional arrangement structure, and is sent to a curing furnace for high-temperature curing and pressed into rock wool products.

[0021] Accord...

Embodiment 3

[0022] Example 3. Pleating method

[0023] The rock wool fibers sprayed with adhesive on the surface are spread into multi-layer rock wool layers with uniform density through the pendulum machine and sent to the pleating machine. The transmission speed V1 of the roller is 15.6m / min, the transmission speed V' of the upper pressing roller is V1 / cos45°=22.06m / min, the transmission speed V2 of the second group of upper and lower pressing rollers is 9m / min, and the third group of upper and lower pressing rollers Transmission speed V3 is 5.2m / min. The first pleat is generated by the difference V1-V2 between the first set and the second set of pressure rollers, and the second pleat is produced by the difference V2-V3 between the second set and the third set of pressure rollers. After the second pleating, the rock wool fiber has a three-dimensional arrangement structure, and is sent to a curing furnace for high-temperature curing and pressed into rock wool products.

[0024] Accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com