Adjustable groove scraping tool

An adjustable and groove-scraping technology, applied in the field of groove-scraping tools, can solve the problems of delayed production cycle, repairing groove-scraping devices, expensive imported tools, etc., and achieves the effects of low cost, accurate adjustment and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

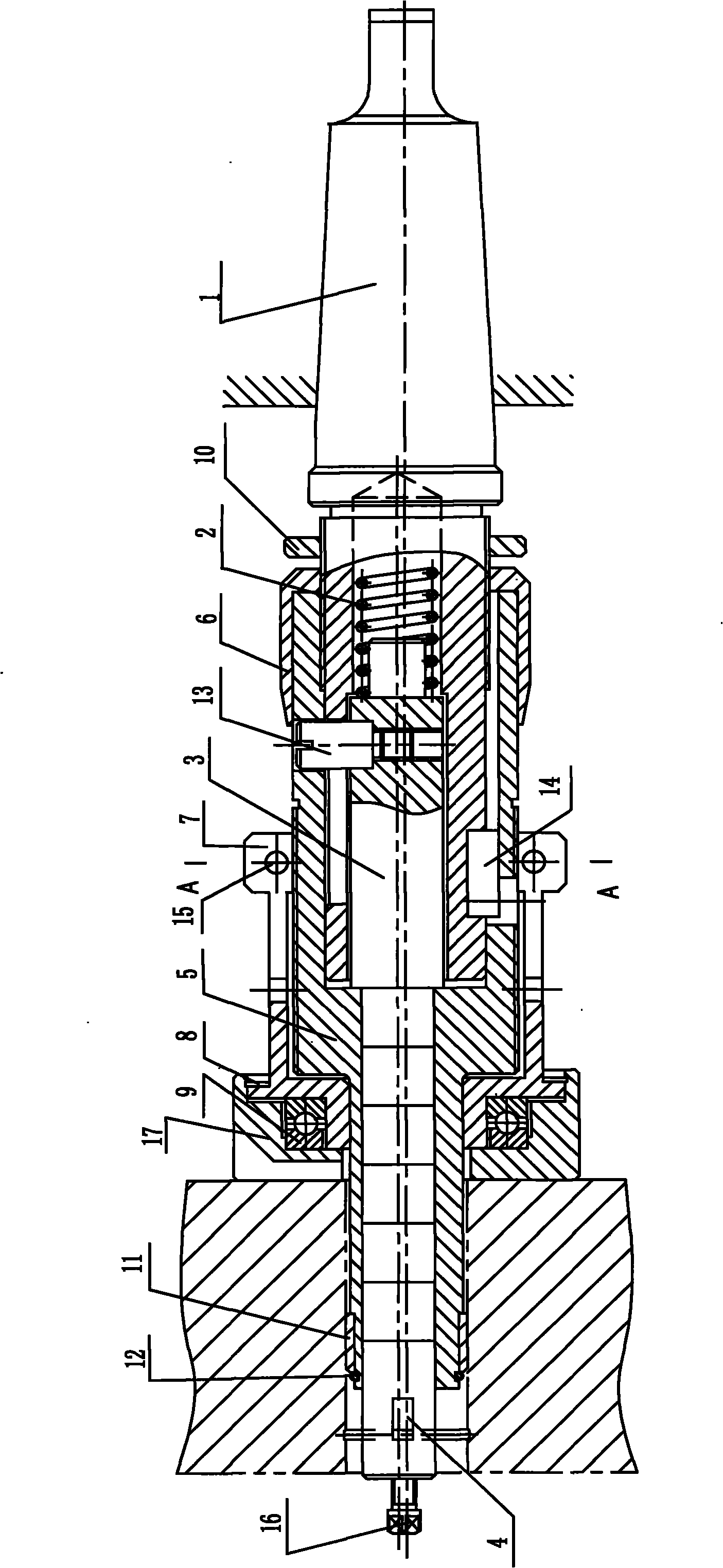

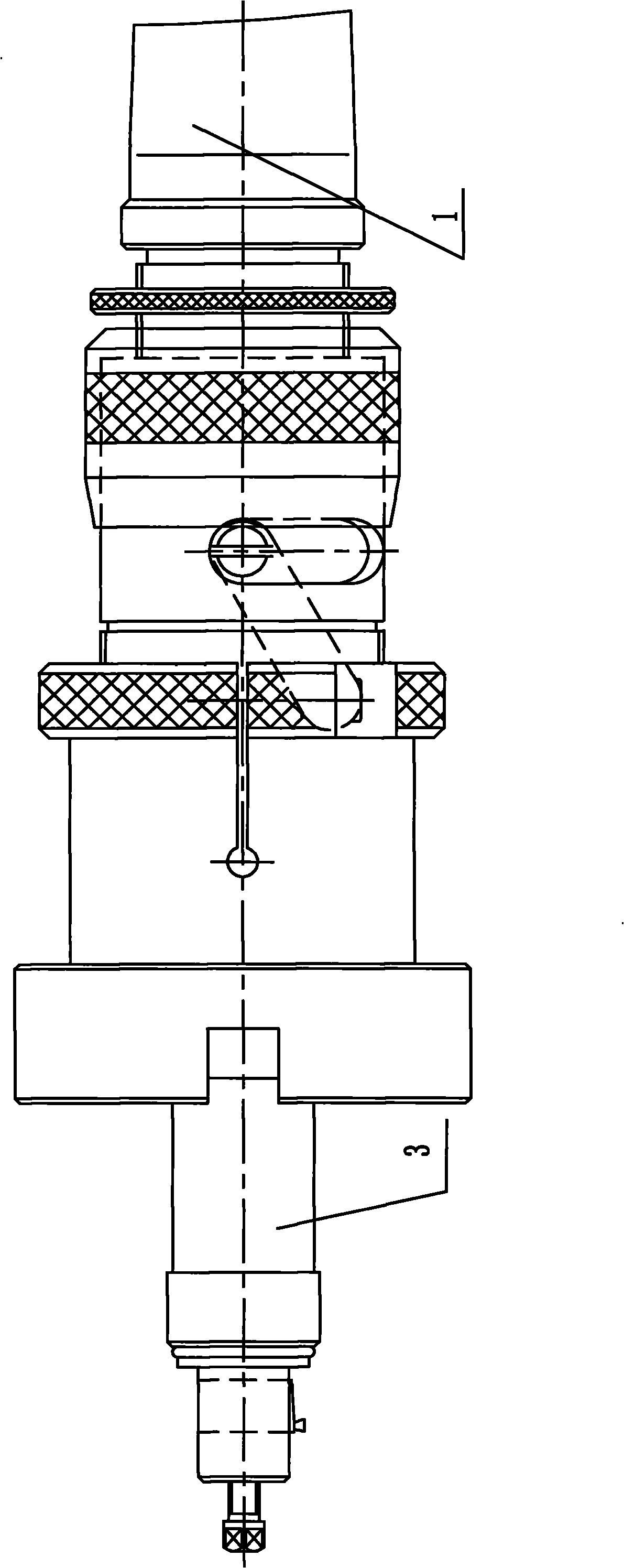

[0018] An adjustable scraping tool, which consists of: a tapered handle 1, the tapered handle 1 is connected with a knife rod 3 with a spring 2, and one end of the knife rod 3 is equipped with a grooving knife 4. The taper shank 1 and the knife rod 3 are covered with a sleeve 5, one end of the sleeve 5 is connected to the adjusting nut 6, the sleeve 5 is connected to the bush retainer 7, and the bush retainer 7 The stop ring 8 and the bearing 9 are connected, the taper shank 1 is connected to the lock nut 10 , and the other end of the sleeve 5 is connected to the copper sleeve 11 and the retaining ring 12 .

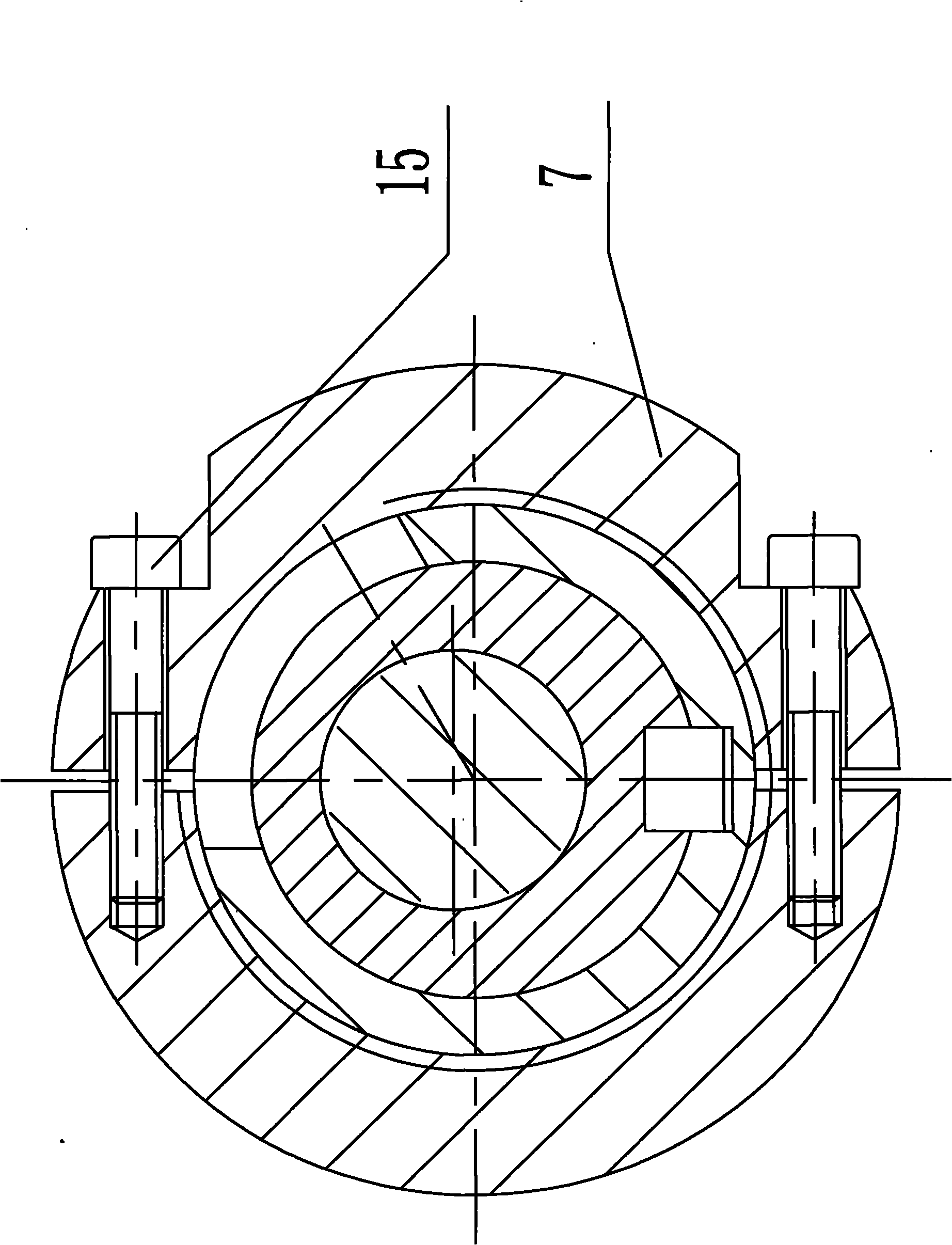

[0019] The adjustable scraping tool is equipped with a guide key 13 at the joint between the tapered handle 1 and the knife bar 3, and a key 14 is installed between the knife bar and the sleeve, Fix 15 with screw between described knife bar and described sleeve, described spring is contained in the other end of knife bar, and described grooving knife is fixed with big scr...

Embodiment 2

[0022] For the adjustable scraping tool described in Example 1, when the aperture of the product is greater than φ30.2mm, the front end of the tool bar of the scraping tool extends into a section of the product hole and a copper sleeve is installed to play a guiding role. The material of the copper sleeve is H62 , to avoid scratching the processed inner wall, and the tolerance requirements are strict, and the processing must be in place.

Embodiment 3

[0024] For the adjustable scraping tool described in Example 1, in order to process the annular groove, the tool rod and the taper handle are designed to have a deviation of 2mm or 3mm, and the parallelism must be ensured after installation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com