Protective device for cleaning machine

A protection device and cleaning machine technology, applied in the field of cleaning machines, can solve the problems of high humidity of the protective cover environment, affecting the normal operation of the cleaning machine, endangering the personal safety of operators, etc., and achieving convenient and fast control and adjustment, convenient installation, and use. Life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

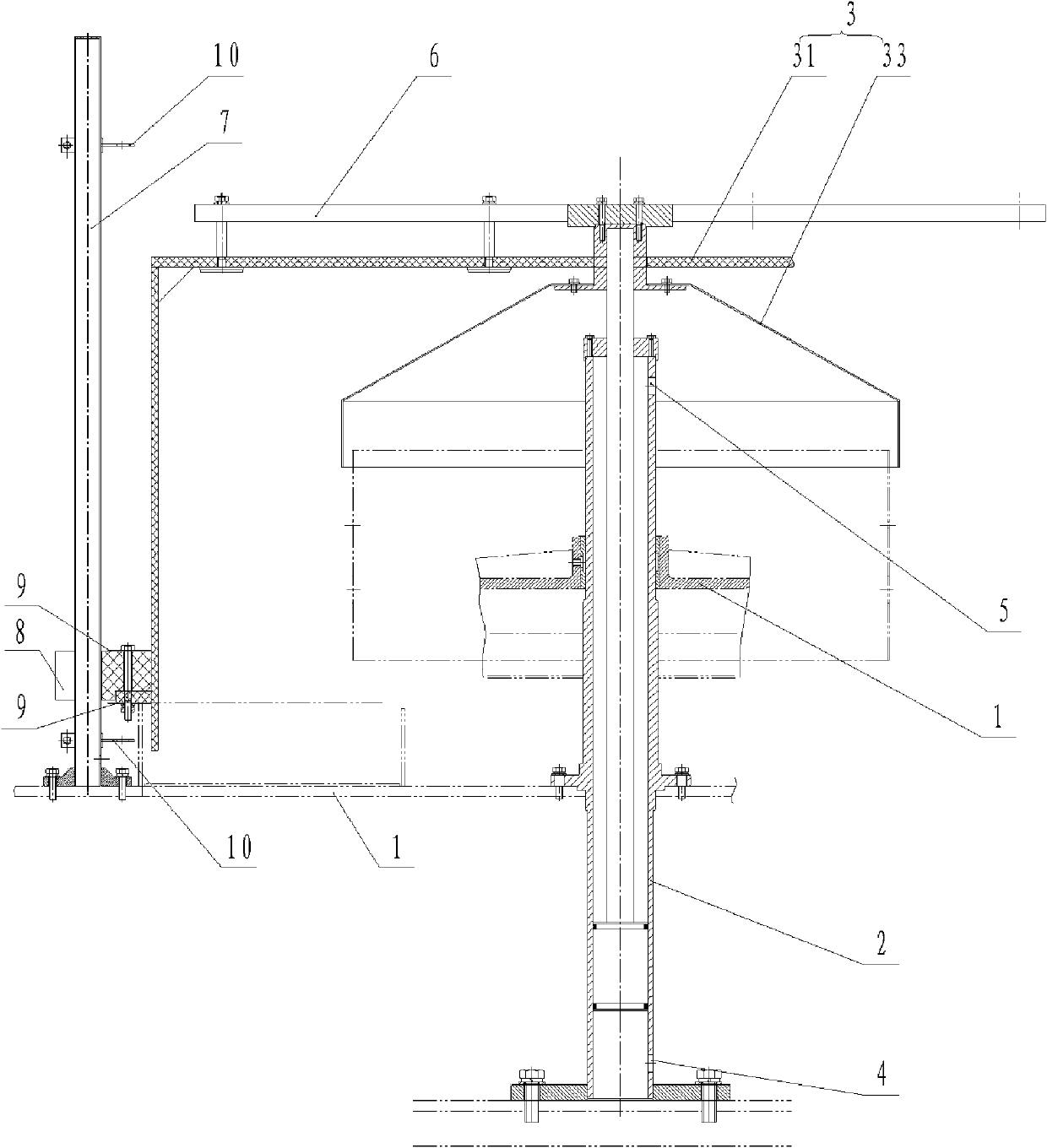

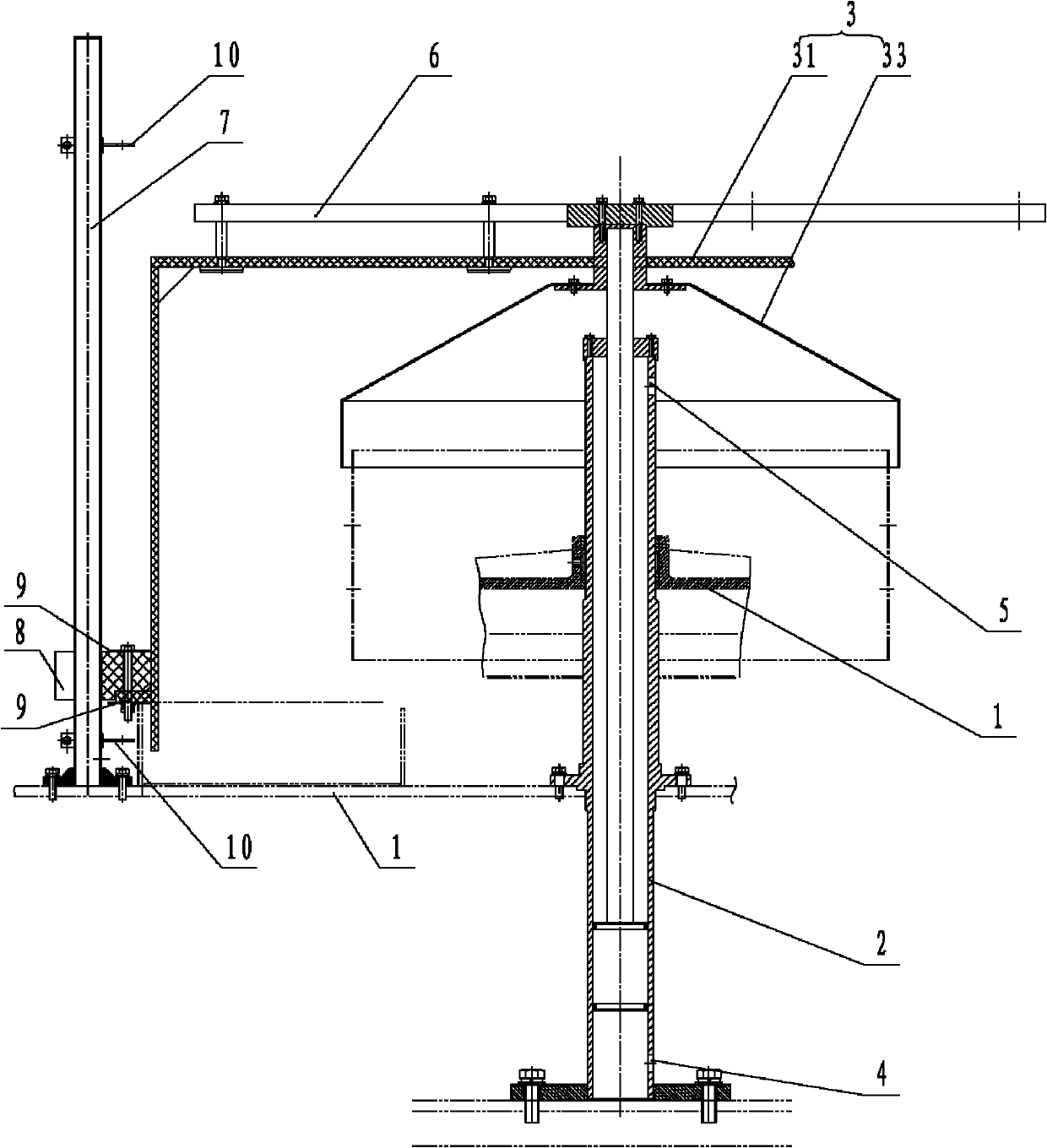

[0018] Such as figure 1 As shown, the protective device for washing machine of the present invention includes a frame 1 and a protective cover 3, the protective cover 3 is connected to the output end of a lifting drive cylinder, and the lifting drive cylinder is installed on the frame 1. The lifting drive cylinder is in the control mechanism (not shown in the figure) drives the protective cover 3 to lift under the control to realize the cover setting and opening of the cleaning machine. Its structure is simple and compact, and the cost is low. Control, its control and adjustment are convenient and quick. At the same time, the lifting drive cylinder is arranged at the rotation center of the protective cover 3, and the frame 1 can be centered through the outer wall of the lifting drive cylinder because it is directly sleeved on the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com