Carbon nanotube fabric and heating body using carbon nanotube fabric

A carbon nanotube and carbon nanotube technology, which is applied in the field of heating elements, can solve the problems of easy rupture, insufficient durability of heating elements, and insufficient carbon fiber strength, and achieves the effects of not easy to rupture, high electrothermal conversion efficiency, and high strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The carbon nanotube fabric provided by the present invention will be described in detail below with reference to the accompanying drawings.

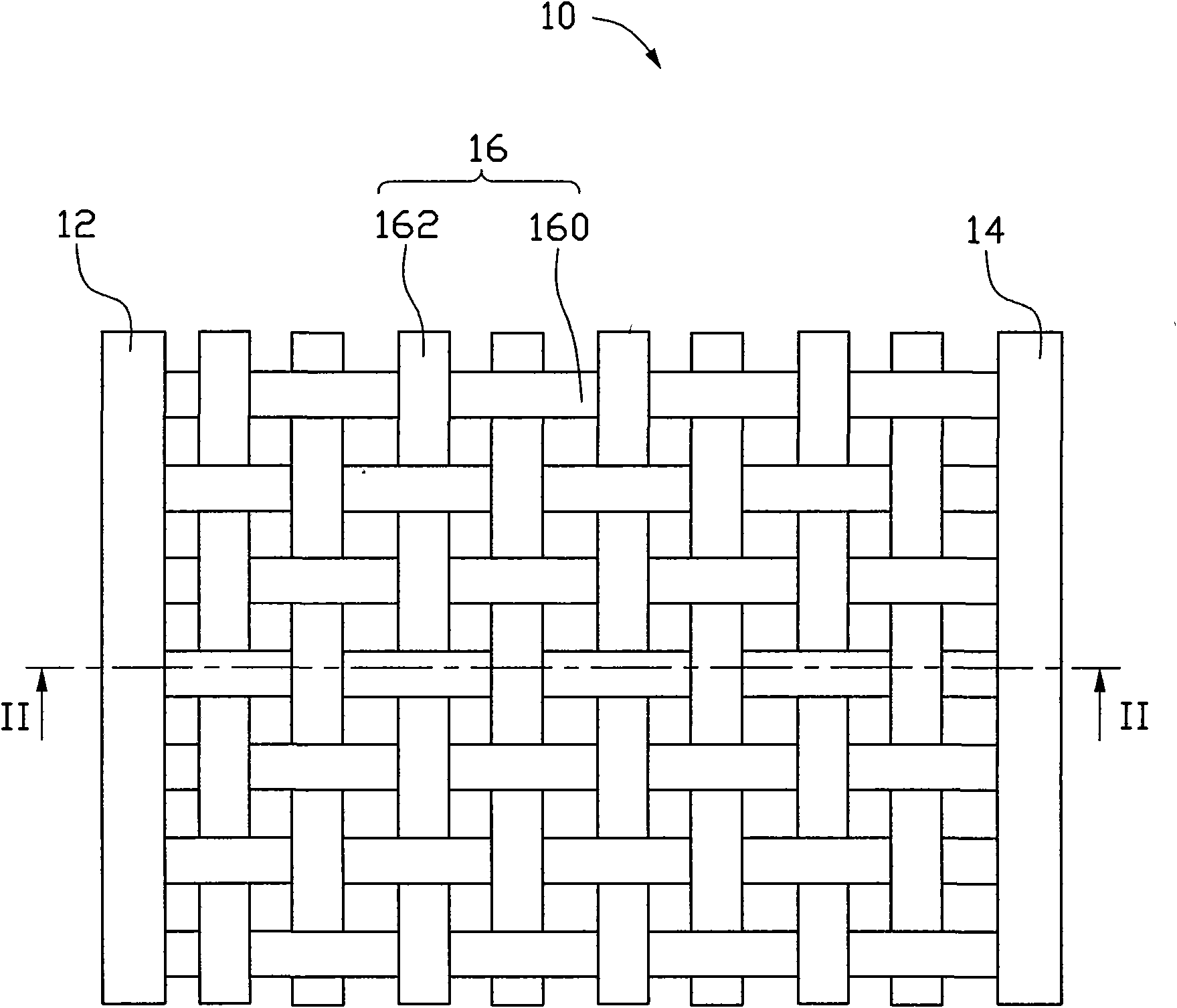

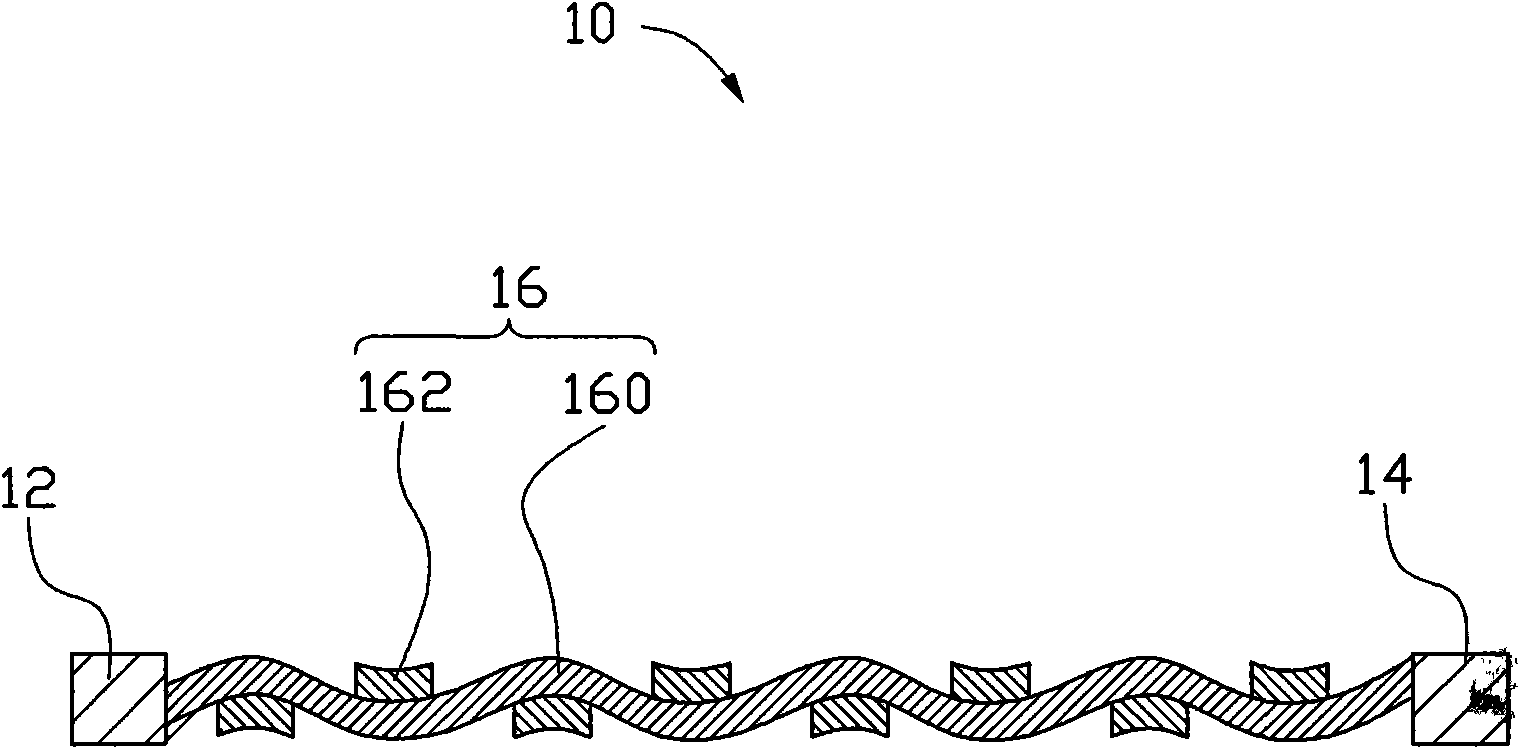

[0022] see figure 1 and figure 2 , The first embodiment of the present invention provides a carbon nanotube fabric 10 , the carbon nanotube fabric 10 includes a heating element 16 , a first electrode 12 and a second electrode 14 . The first electrode 12 and the second electrode 14 are electrically connected to the heating element 16 .

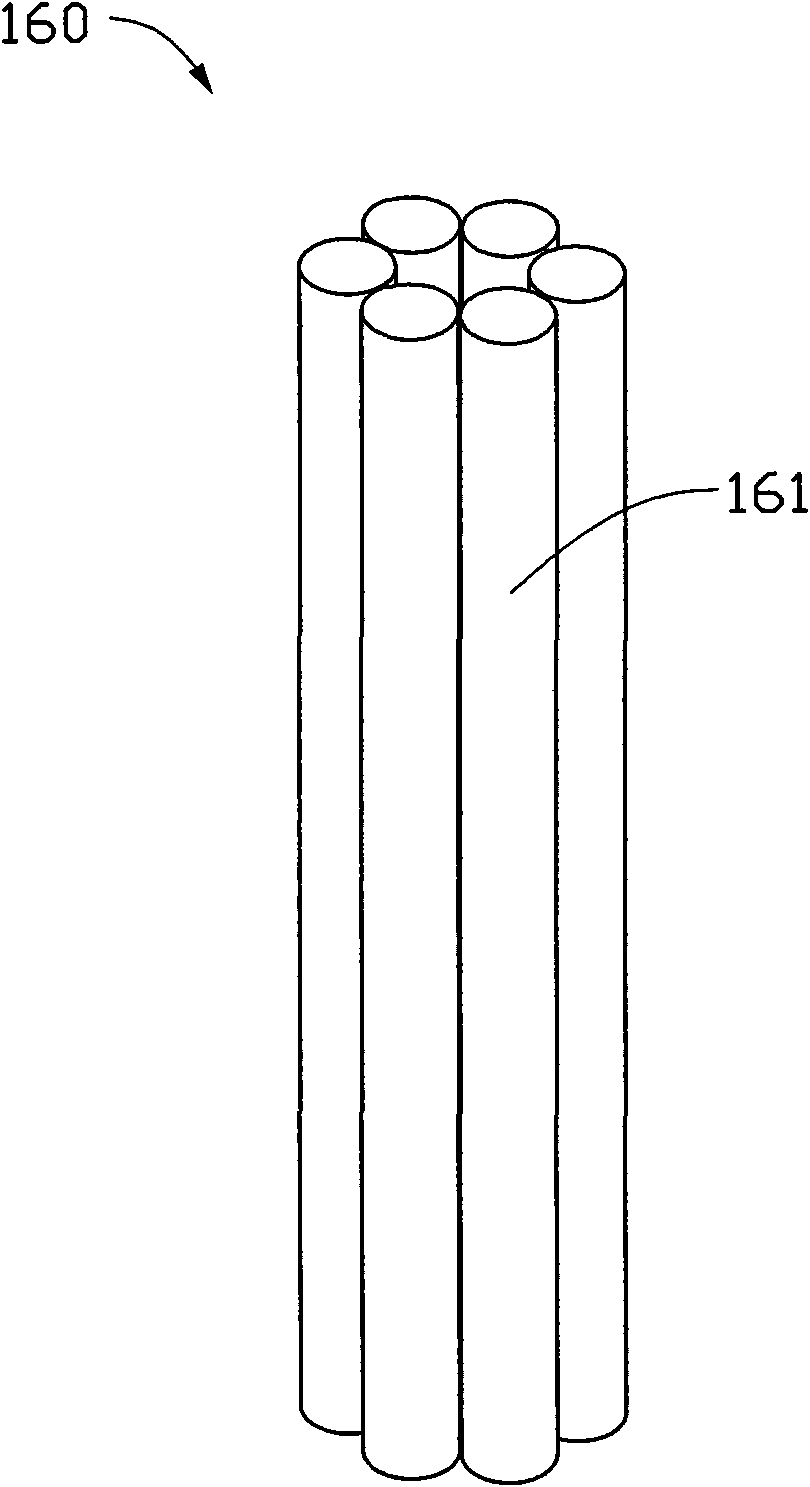

[0023] The heating element 16 includes at least one carbon nanotube wire structure 160 and at least one base wire 162 . The first electrode 12 and the second electrode 14 are electrically connected to the carbon nanotube linear structure 160 . The heating element 16 can be woven from carbon nanotube wire structure 160 and base thread 162 . The weaving method of the carbon nanotube linear structure 160 and the base thread 162 is not limited. Specifically, the carbon nanotube linear structure 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com