Generation method of one-way aperiodic vibration of single motor and one-way aperiodic vibration device

A generation method and vibration device technology, applied in the direction of electromechanical devices, electric components, electrical components, etc., can solve the problems of difficult online adjustment of parameters, inflexible design, and large mechanism, etc., and achieve reasonable stress distribution, simple counterweight, and wide frequency spectrum Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

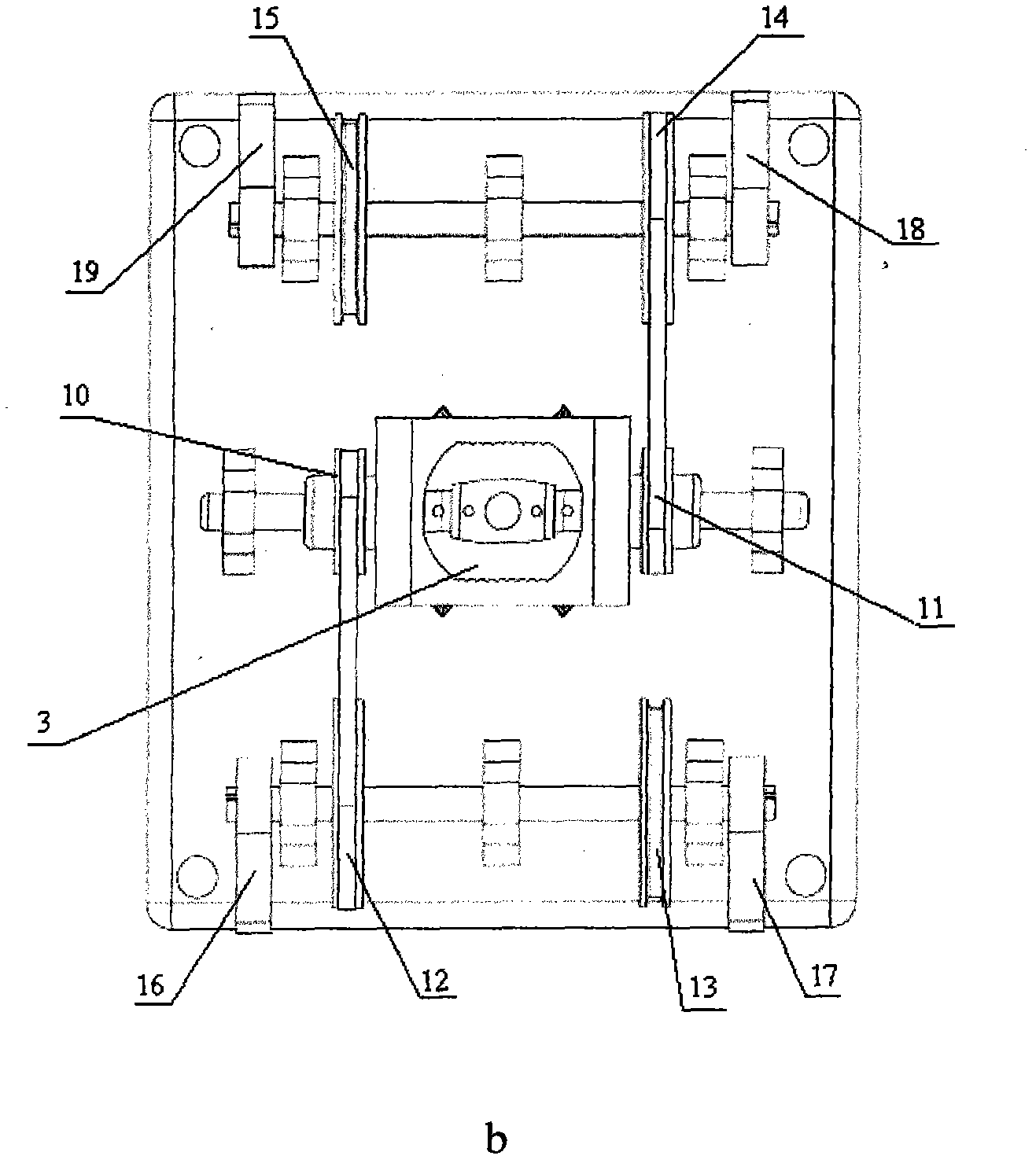

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] The principle of traditional vibratory compaction machinery such as figure 1 As shown, the high-frequency vibration generated by the vibrator fixed on an object is transmitted to the pressed material to make it vibrate, and the small particles are filled into the pores of the large particles, and the degree of compaction increases.

[0033] The method of the present invention adopts a single motor and a transmission system to realize unidirectional non-periodic vibration, and the specific method is:

[0034] 1) Select the motor and controller

[0035] Use permanent magnet synchronous motor or asynchronous motor, and adopt appropriate control method to make the motor speed a non-periodic signal;

[0036] The direct delay feedback control method can be used to make the motor speed appear aperiodic motion, and the direct delay f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com