Gas stove

A technology of gas stoves and burners, which is applied in the field of gas stoves, and can solve the problems of inconvenient cleaning of panels and pot supports, large contact area, and obsolescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

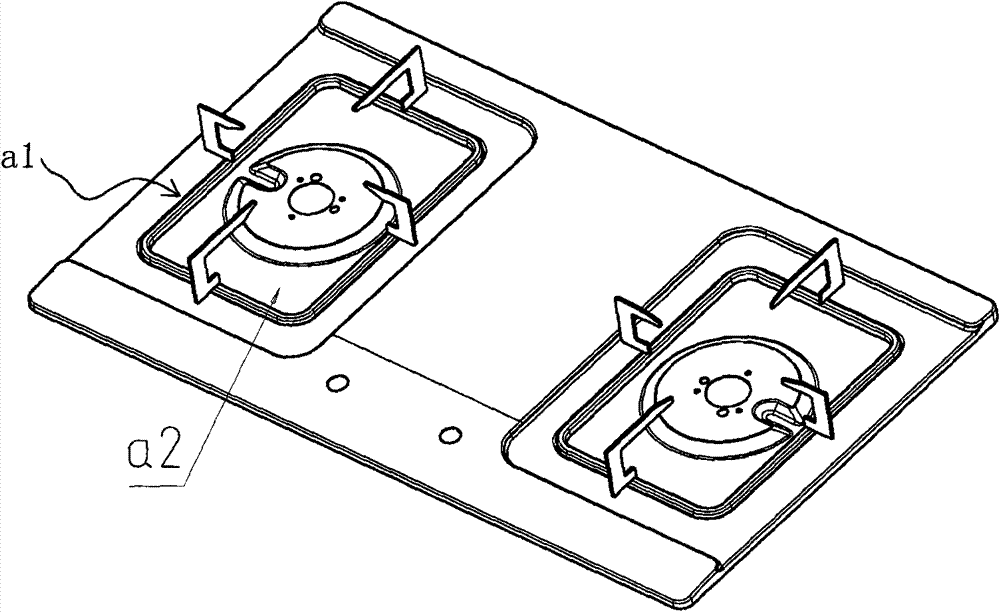

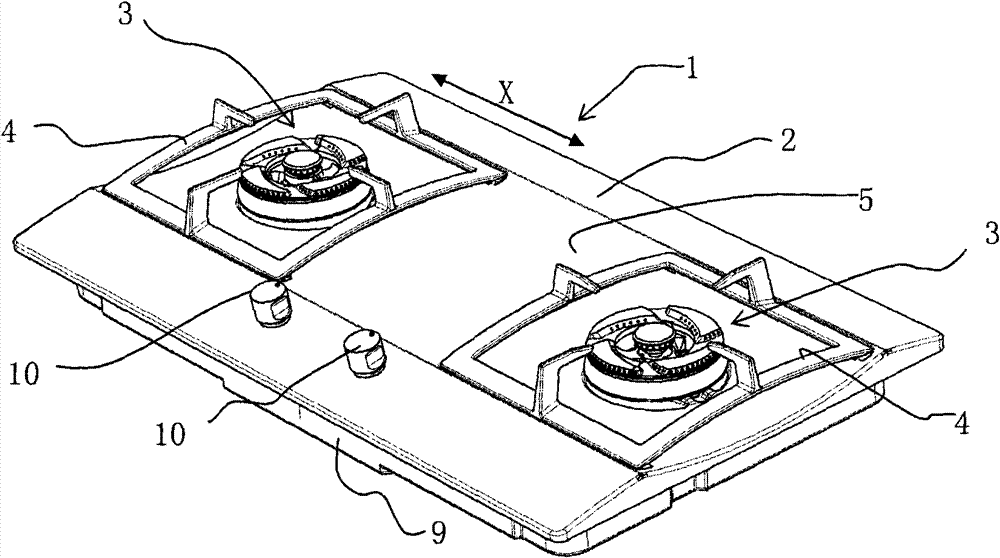

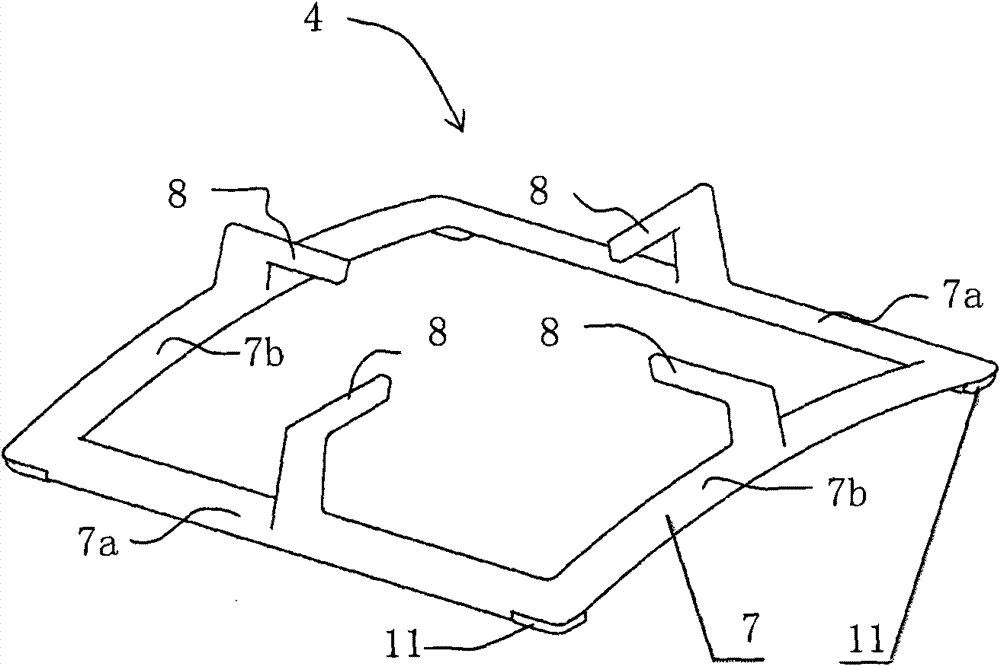

[0027] See attached figure 2 , A gas stove 1 provided by the present invention includes a panel 2, a burner 3 and a pot support 4 arranged on the panel. The switch 10 for controlling the gas cooker is arranged on the panel. It is connected with the panel 2 to form the lower casing 9 of the gas cooker casing. The panel 2 is provided with a groove 5 whose extending direction is parallel to the transverse direction of the panel. The horizontal direction of the gas cooker panel proposed by the present invention, such as figure 2 and Figure 4 The double-headed arrow X in the middle refers to the direction of the horizontal edge of the gas cooker panel facing the user of the gas cooker under the working state of the gas cooker. The longitudinal section of the groove 5 is arc-shaped, and a structure for placing burners is arranged at the bottom of the groove 5 , and the pot support 4 straddles the edge of the groove 5 . This kind of design can reduce the area that needs long-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com