Multipurpose ultrahigh-pressure packer tester

A test device and ultra-high pressure technology, applied in sealing/isolation, measurement, wellbore/well components, etc., can solve the problems of high construction cost, long construction period, and unsatisfactory results, so as to shorten the development period and save cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

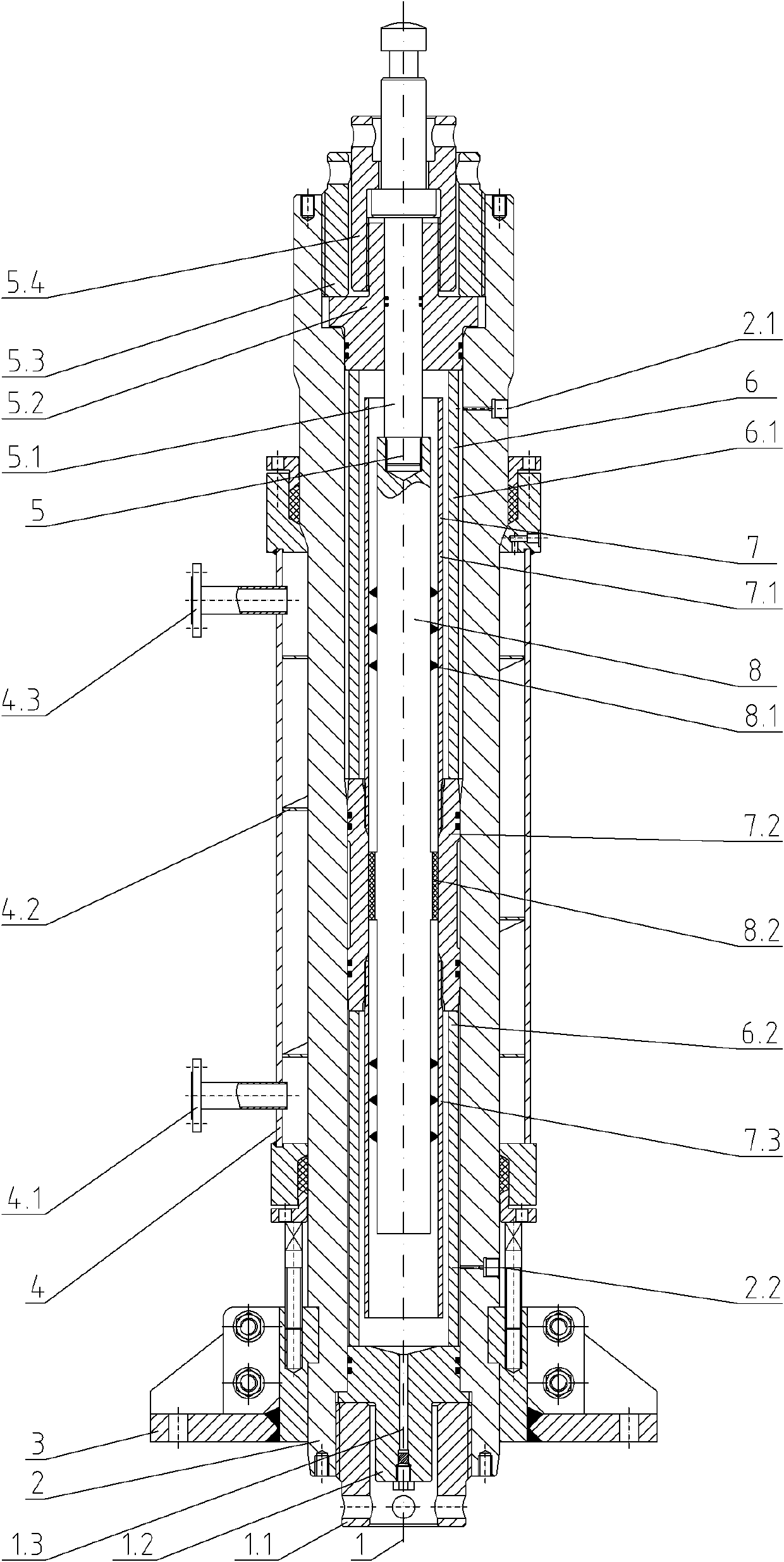

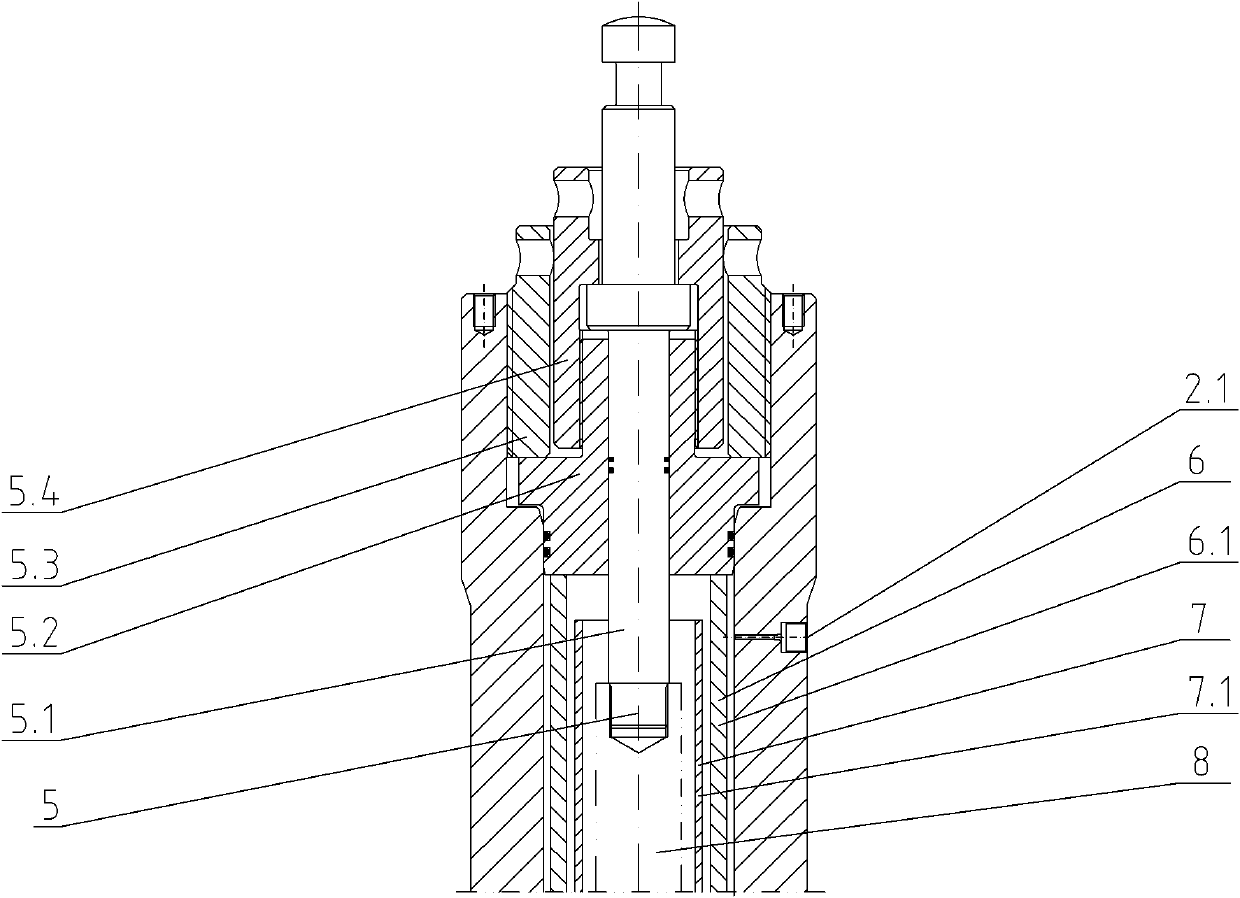

[0028] Such as figure 1 , 3 The first multi-purpose ultra-high pressure packer test device shown in . The test auxiliary components 6 and 7 inside the ultra-high pressure cylinder body 2 are composed of a heating jacket 4 arranged on the outer wall of the ultra-high pressure cylinder body 2 .

[0029]The ultra-high pressure cylinder 2 is an annular cylinder whose lower and upper ends are respectively provided with connecting threads and sealing surfaces matched with the lower sealing structure 1 and the compression upper sealing structure 5. The upper and lower ends of the cylinder wall are respectively There are upper inlet pressure port 2.1 and lower inlet pressure port 2.2.

[0030] The lower sealing structure 1 includes a lower sealing head 1.2 and a lower threaded pressure ring 1.1. The upper cylindrical surface of the lower sealing head 1.2 is closely attached to the lower sealing surface of the ultra-high pressure cylinder 2 through the sealing ring, and the lower thr...

Embodiment 2

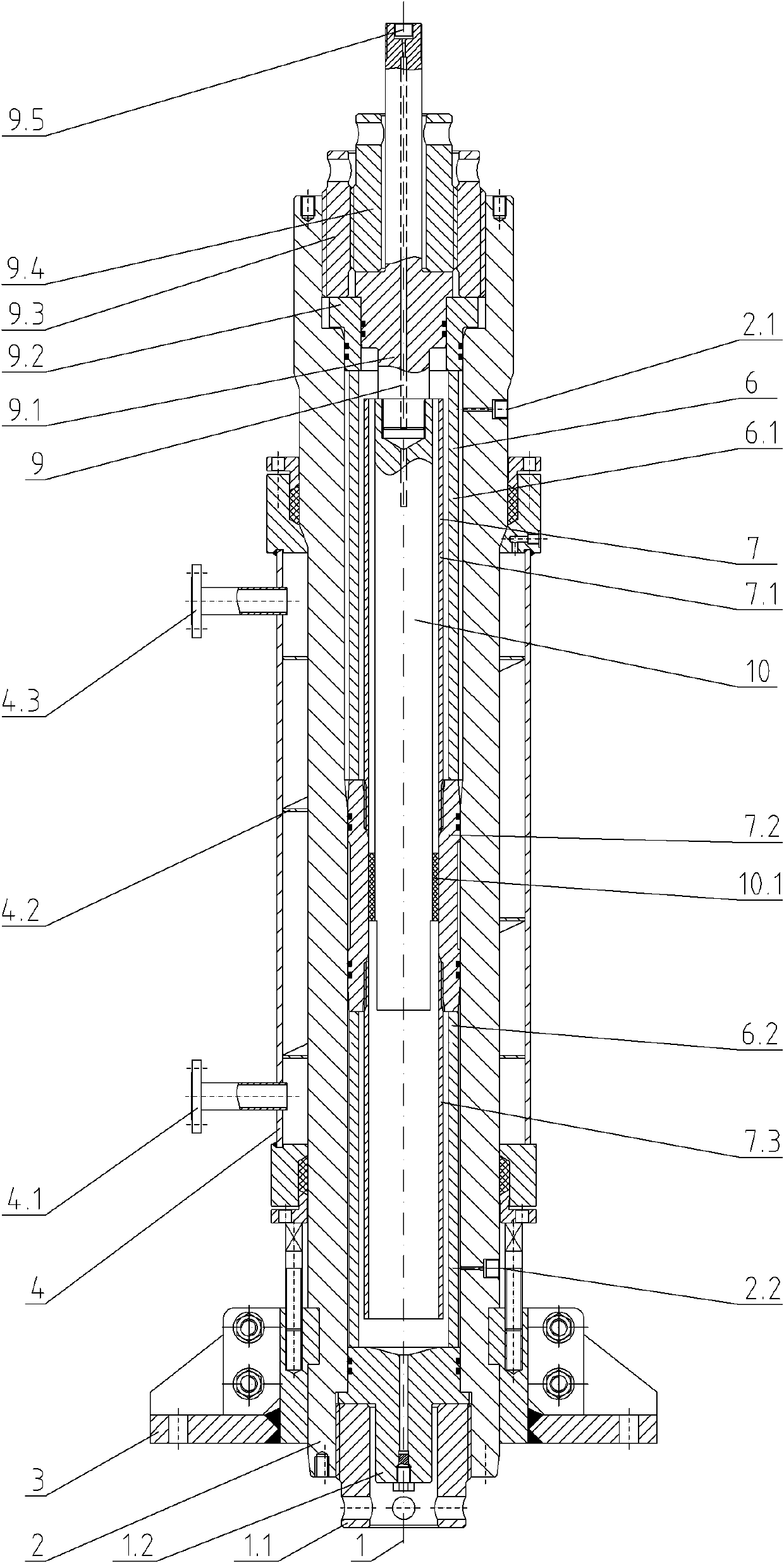

[0038] Such as figure 2 , 4 , 6 shows the second multi-purpose ultra-high pressure packer test device, the structure of the ultra-high pressure cylinder 2, the lower sealing structure 1, the test auxiliary components 6 and 7, and the heating jacket 4 are basically the same as above, and the I won't go into details here. The difference is that the compressive upper sealing structure 5 is replaced by an expanding upper sealing structure 9 . The expansion-type upper sealing structure 9 includes a second connecting rod 9.1, a second upper sealing head 9.2, a second upper threaded pressure ring 9.3 and a third upper threaded pressure ring 9.4, and the lower cylindrical surface of the second upper sealing head 9.2 and the ultra-high pressure cylinder The sealing surface of the upper end of the body 2 is closely attached, and the second upper threaded pressure ring 9.3 is threadedly connected with the inner wall of the upper end of the ultra-high pressure cylinder body 2, and is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com