Method and equipment for using waste gas of butadiene extraction unit

An extraction device and butadiene technology, applied in chemical instruments and methods, gas mixture processing, hydrocarbon oil treatment, etc., can solve the problems of diene and alkyne polymerization, catalyst deactivation, etc., and reach the content of alkyne Reduce, maintain catalytic performance, reduce the effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

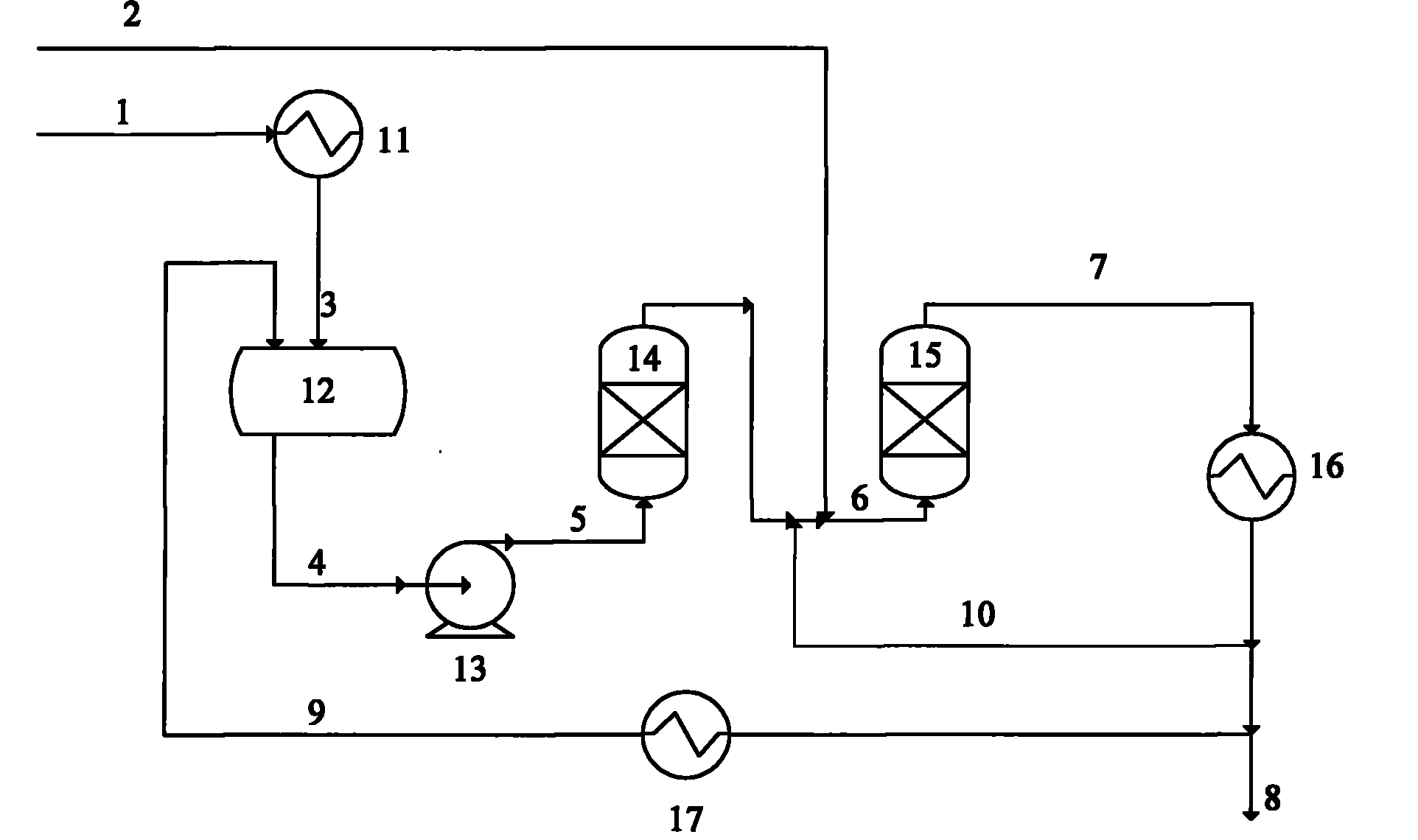

Embodiment 1

[0043] 1. Condensation: tail gas 1 from the butadiene extraction unit (main composition: butene 0.5%, butadiene 56.3%, ethyl acetylene and vinyl acetylene 40.8%, carbon five 2.4%), flow rate 1200kg / h, Pressure 0.1MPa (absolute pressure). The tail gas is condensed into a liquid phase material 3 through the condenser, the temperature is -5°C, the liquid phase mixture enters the mixing tank 12, and is mixed with the dilute alkane 9 from the reactor product, the flow rate of the dilute alkane 9 is 1200kg / h, and the temperature is -3 °C, pressure 0.1MPa, the content of ethylacetylene and vinylacetylene in the mixed material 4 is 20%;

[0044] 2. Boosting: the diluted mixture flow 4 is boosted to 2.0-2.5MPa by the pump, and a booster pump with high speed and high head can be selected;

[0045] 3. Drying: the pressurized mixture 5 enters the drier 14 for drying to remove trace moisture therein;

[0046] 4. Reaction: The dried mixture is mixed with the circulating alkane 10, the flo...

Embodiment 2

[0051] Adopt flow process described in embodiment 1, change the composition of stream 1, the quality composition of each main stream of hydrogenation reaction is as follows table 2:

[0052] Table 2

[0053] logistics number 1 2 3 4 5 6 7 8 9 10 temperature °C 35 25 -5 -5.1 -2.3 37.3 50.5 40 40 40 pressure MPa 0.1 3 0.1 0.1 2.0 2.4 2.0 1.9 0.1 1.9 Mass flow kg / h 1200 108 1200 4799.6 4799.6 74834.3 74909 1309 3600 70000 quality composition hydrogen 0 0 0 0 0.001 0 0 0 0 propane 0 0 0.008 0.008 0.01 0.01 0.01 0.01 0.01 propyne 0.01 0.01 0.002 0.002 0 0 0 0 0 Isobutane 0 0 0.024 0.024 0.031 0.032 0.032 0.032 0.032 n-butane 0 0 0.706 0.706 0.926...

Embodiment 3

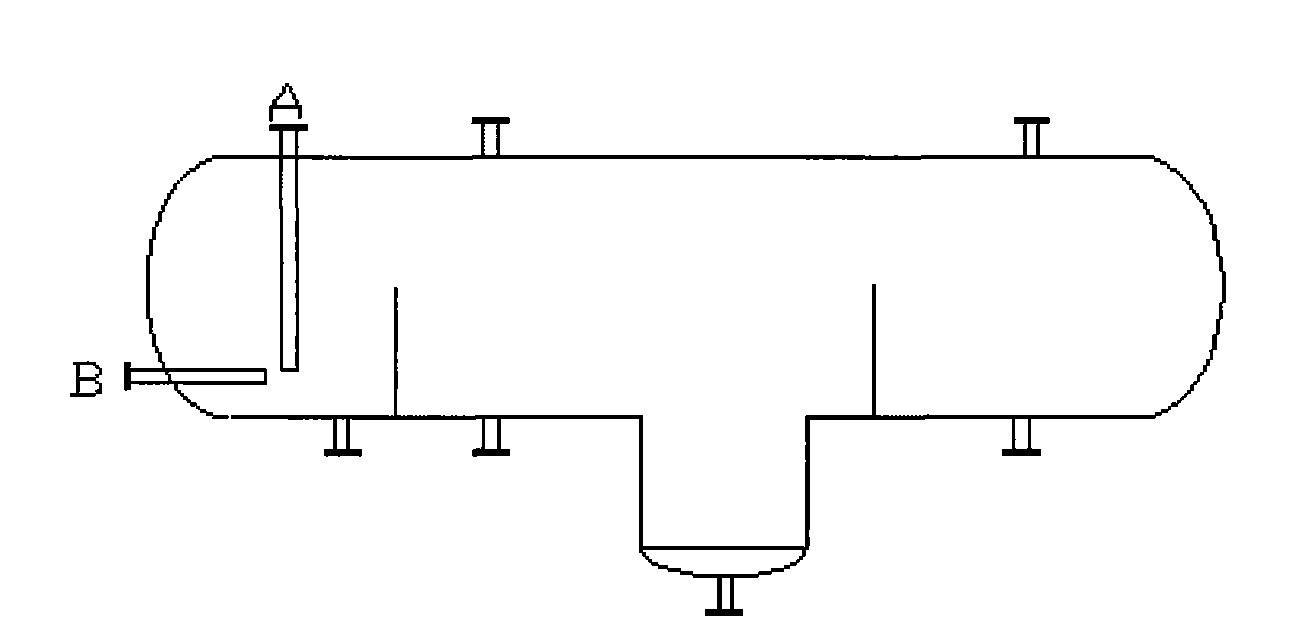

[0055] combined with figure 2 and image 3 As shown, the structure of the mixing tank used in Examples 1 and 2 is as follows: tail gas condensate 3 is fed from the top of the mixing tank by gravity, and the feed port is 1 / 3 of the tank diameter from the bottom of the mixing tank; Feeding along the horizontal direction, the distance between the feed inlet and the feed inlet of the condensate 3 is 3 times the diameter of the raw material pipe; the vortex baffle is set up at the inlet of the booster pump at 1 / 3 of the length of the mixing tank, and the height of the baffle is dia. 2 / 3 of that; the alkane used for dilution enters the mixing tank and forms a vortex in the tank, which can be fully mixed with the liquid phase raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com