Refueling machine

A fuel dispenser and oil gun technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of easy mopping, reduced service life, easy gun jamming, etc., to solve the problem of oil pipe mopping the floor, prolong the service life, and facilitate The effect of raising the gun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

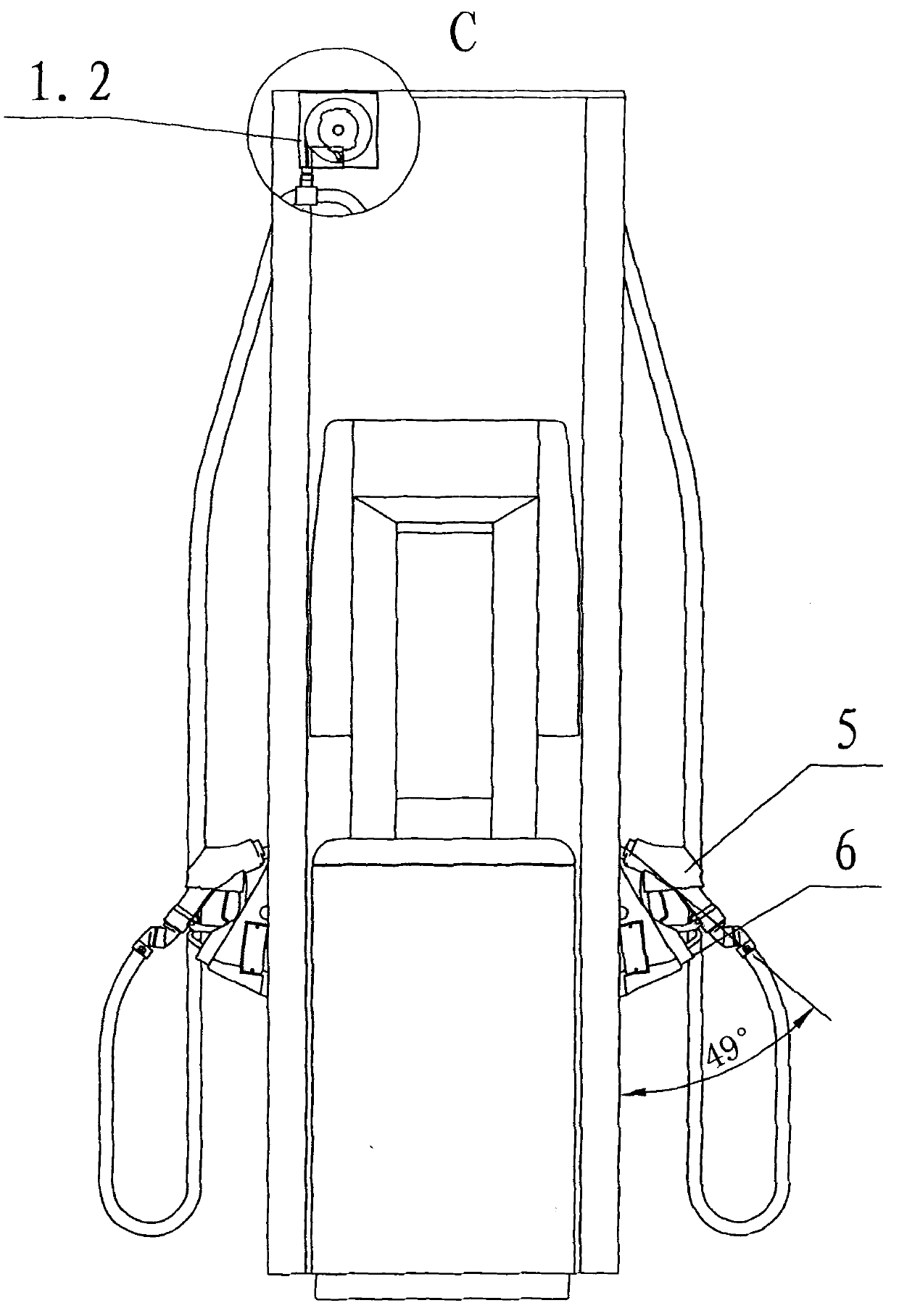

[0040] see Figure 1-Figure 3 , a kind of oil dispenser that the present invention relates to, it is mainly made up of tower box 1, hydraulic oil tank 2, control box 3, oil pipe 4, oil gun 5, oil gun cover 6, motor 7, oil pump 8 and belt 9;

[0041] The side of the tower box 1 is connected to the hydraulic oil tank 2, and the two form an "L"-shaped structure, and the control box 3 is arranged above the hydraulic oil tank 2 .

[0042] The front and rear sides of the tower box 1 are curved or polygonal, and the curved or polygonal surfaces are provided with a plurality of oil gun cover panels 11, and each of the oil gun cover panels 11 is provided with an oil gun cover panel 11. Gun cover 6, the oil gun cover 6 is provided with an oil gun 5, the oil gun 5 is connected to the output end of the oil pump 8 through the oil pipe 4, and the power end of the oil pump 8 is connected to the output end of the motor 7 through a belt 9; Said belt 9 is provided with tensioner 10, which is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com