Electric and manual integrated planet driving device

A planetary drive and electric technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems that manual and electric drives cannot operate independently, and the structure of planetary drive devices is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

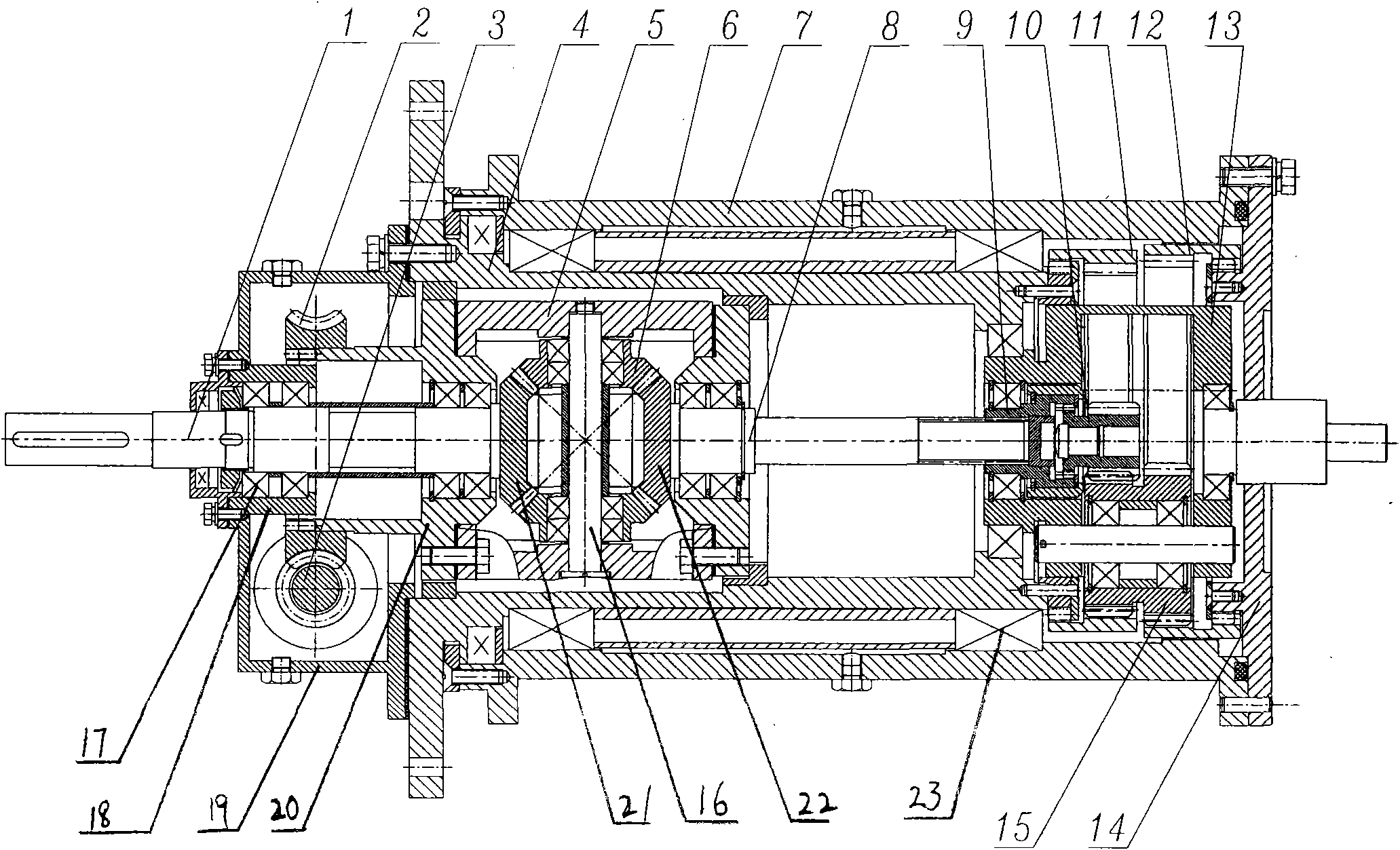

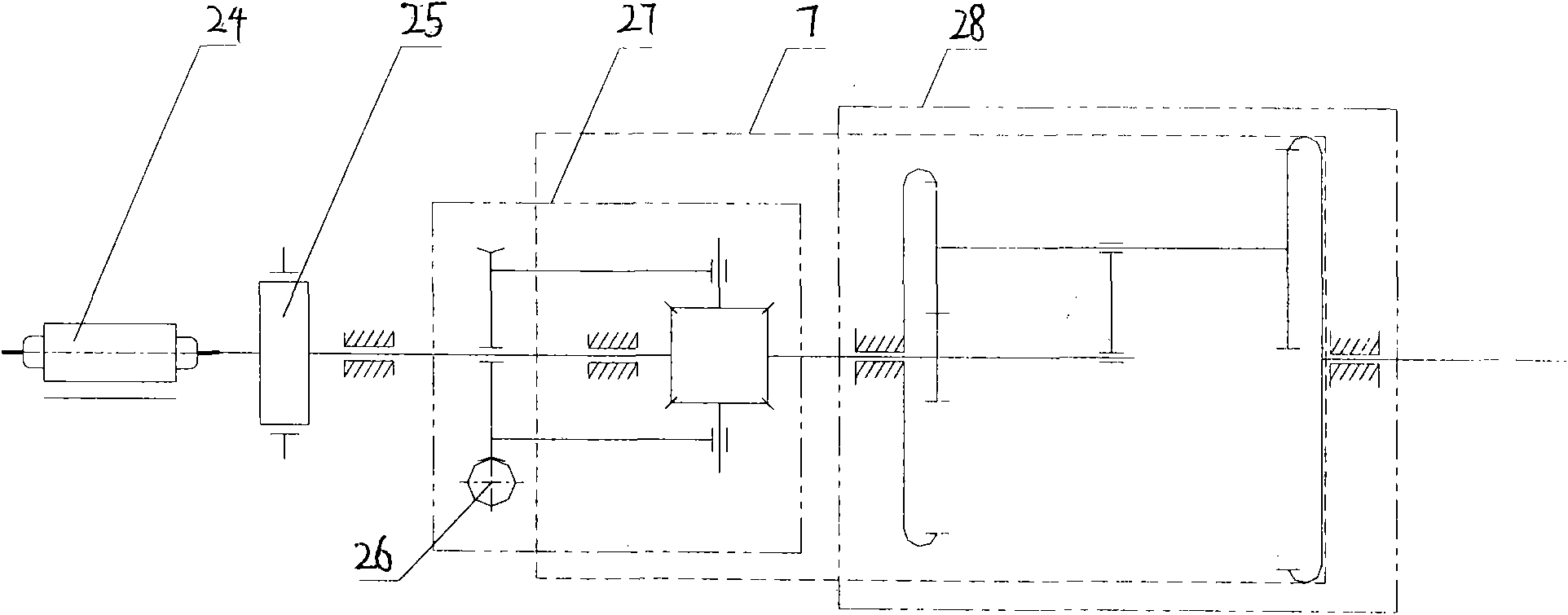

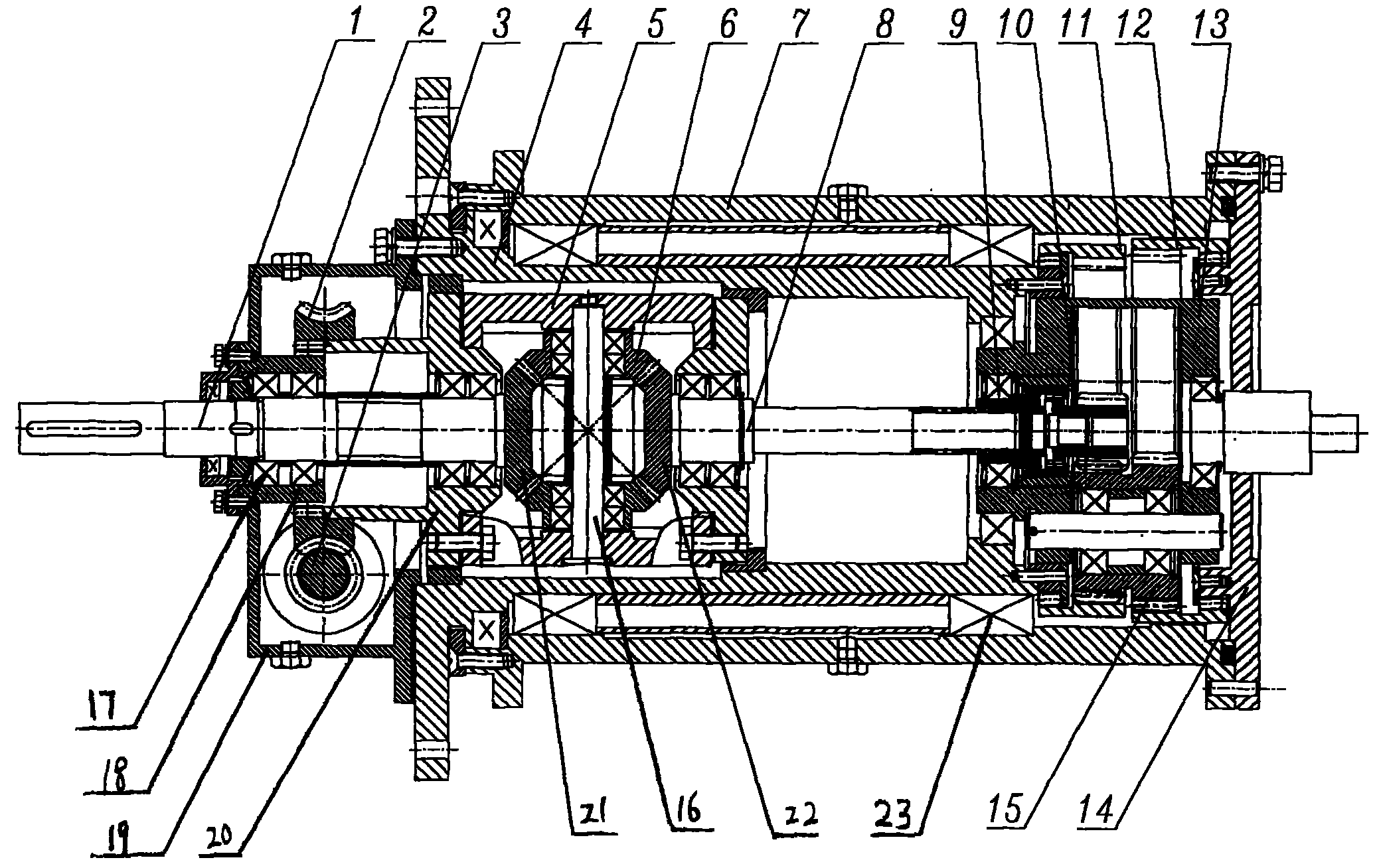

[0011] Such as figure 1 As shown, the present invention includes a motor, the motor is connected with a shaft coupling, the shaft coupling is connected with an input gear shaft 1, an output gear shaft 8 is arranged at the right end of the input gear shaft 1, and a sun gear system with planetary gears is arranged outside the output gear shaft 8, and the sun gear An outer reel end cover 14 is arranged outside the system, and the outer reel end cover 14 is connected with the outer reel 7. The outer reel 7 is provided with a bearing III 23, and the bearing III 23 is provided with an inner reel 4 and an inner reel 4 It is connected with the sun gear system of the planetary gear arranged in the outer reel 7 , and the left end of the outer reel 7 is connected with the left end of the inner reel 4 . The sun gear system meshes with the output gear shaft 8 through the spline sleeve 9; the input gear shaft 1 is provided with a bearing I 17, and the bearing I 17 is provided with a shaft s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com