Method for controlling oil injection of diesel engine

A diesel engine and control method technology, applied in engine control, fuel injection control, machine/engine, etc., can solve the problems of limiting exhaust smoke, failure of control system smoke limit function, and inability to detect supercharger abnormality in real time, etc. Achieve the effect of reducing costs and avoiding excessive exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

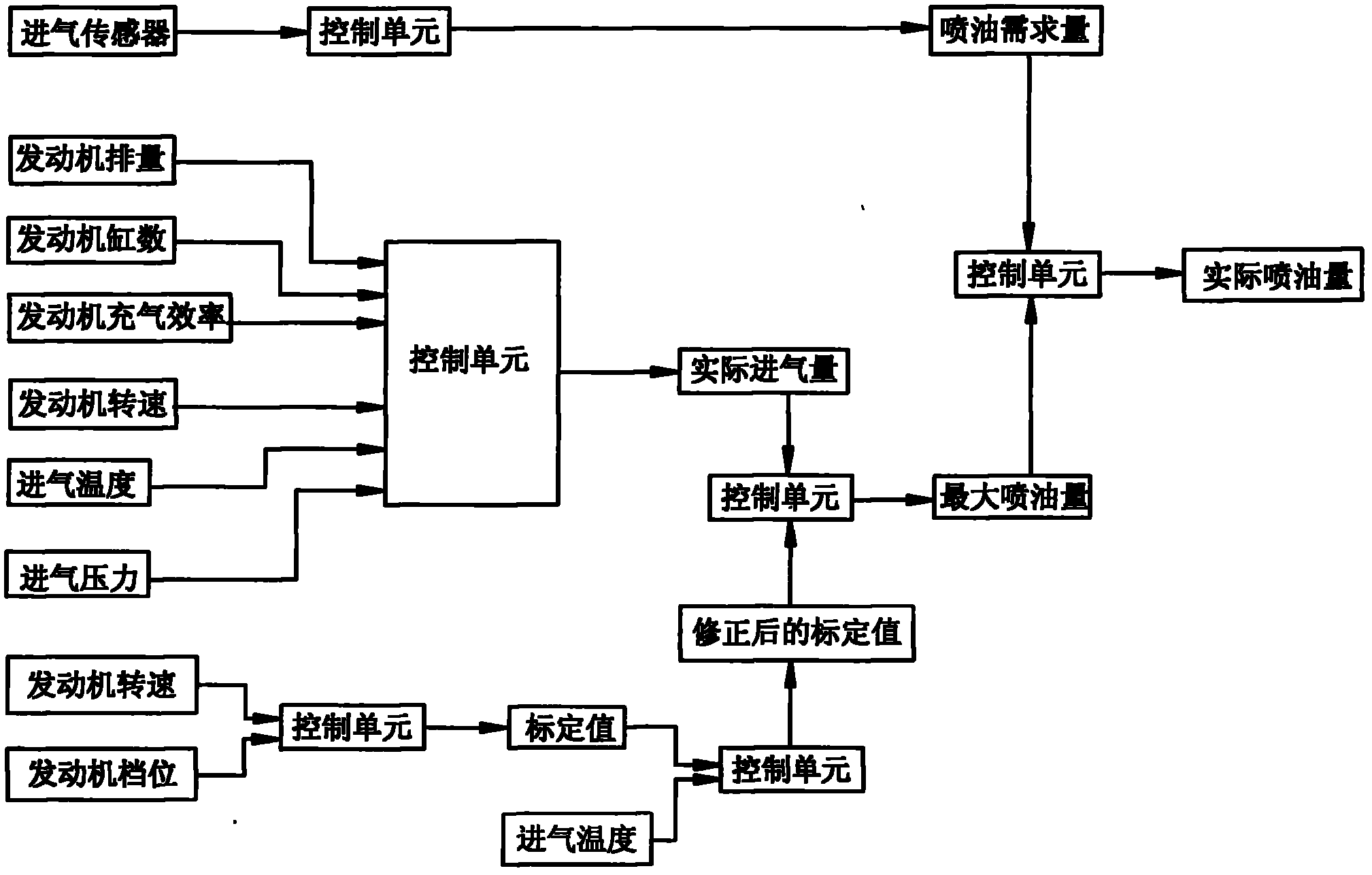

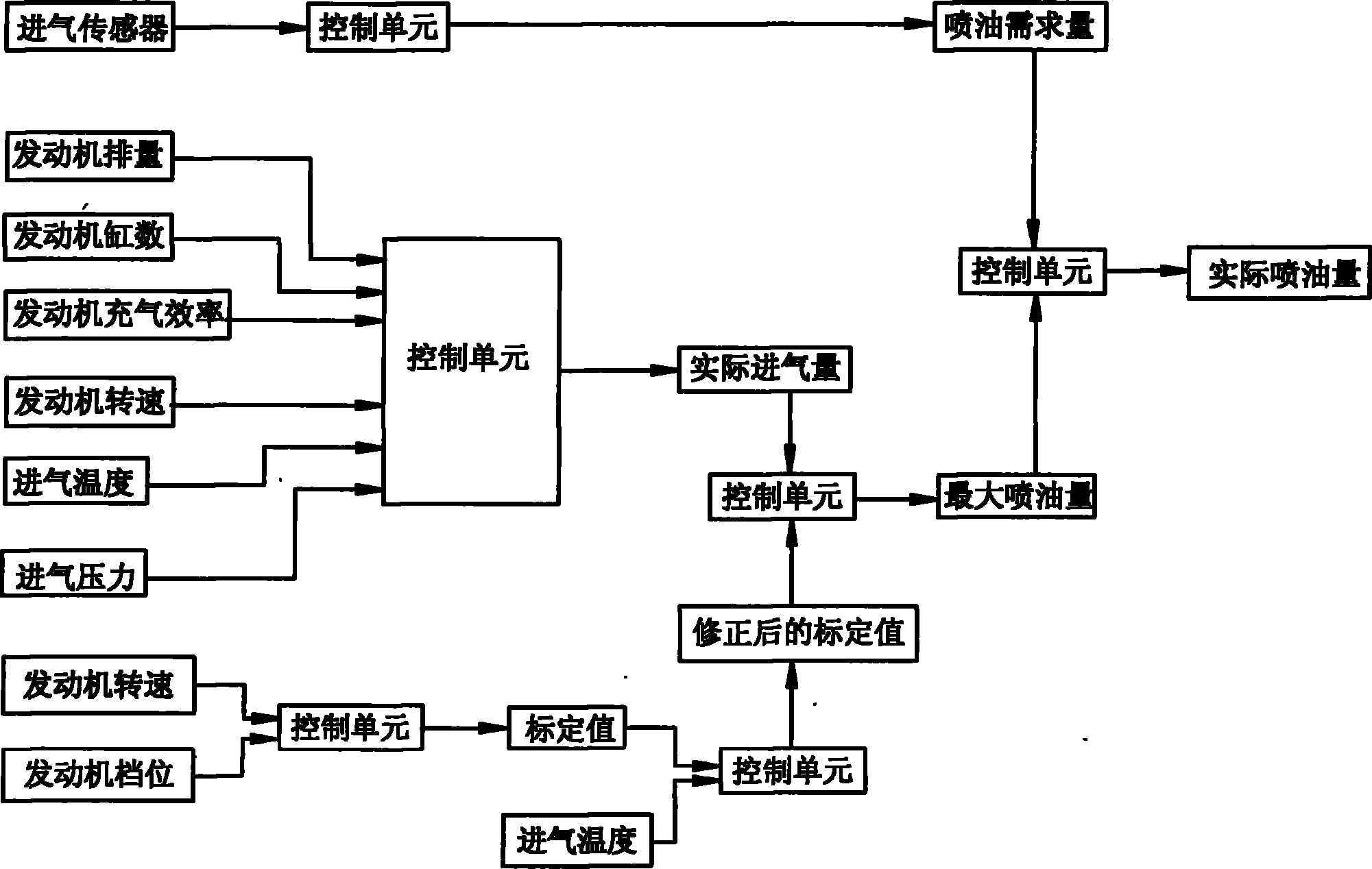

[0020] Such as figure 1 As shown, in the fuel injection control method of the diesel engine in this embodiment, the control unit calculates the fuel injection demand according to the intake air quantity measured by the intake sensor; The actual intake air volume is calculated from the actual intake pressure measured by the engine charging efficiency, engine speed, intake air temperature information and boost pressure sensor in the supercharging system, and is calibrated according to the engine speed information and engine gear information look-up table value, and then correct the calibration value according to the intake air temperature, and finally obtain the maximum fuel injection volume according to the actual intake air volume and the calibration value after correction; The ratio of the intake air volume to the fuel injection volume when the maximum torque is released and the exhaust gas reaches the standard; when the fuel injection demand is greater than the maximum fuel ...

Embodiment 2

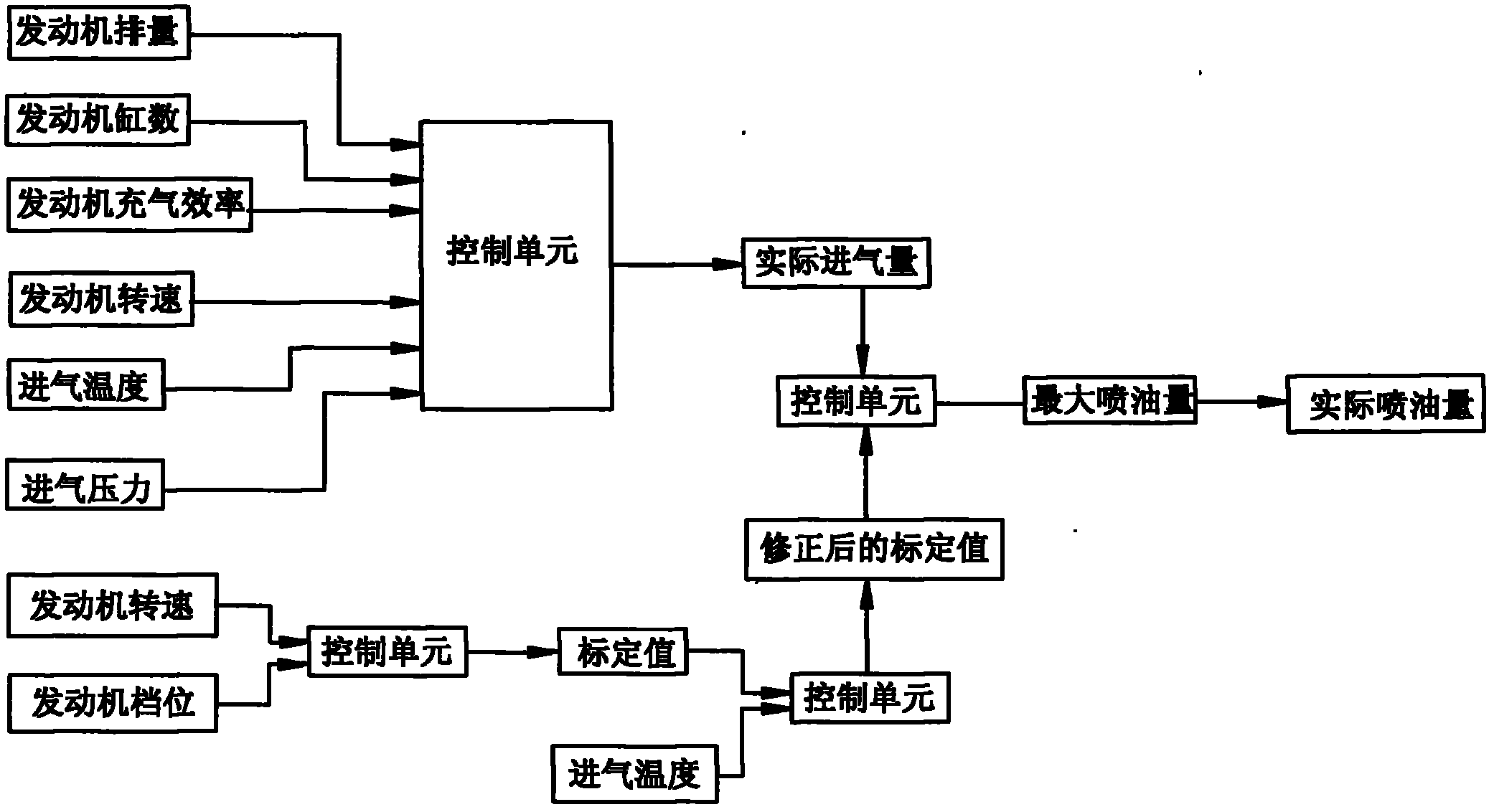

[0024] Such as figure 2 As shown, in the fuel injection control method of the diesel engine of the present embodiment, the control unit is based on the engine displacement, the number of engine cylinders, the engine charging efficiency, the engine speed, the intake air temperature information and the boost pressure sensor in the boost system. The actual intake pressure is calculated to calculate the actual intake air volume, and the calibration value is obtained according to the engine speed information and engine gear information, and then the calibration value is corrected according to the intake air temperature. Finally, the actual intake air volume and the corrected The calibration value obtains the maximum fuel injection volume, and controls the actual fuel injection volume according to the maximum fuel injection volume; the calibration value is obtained through pre-test when the engine emits the maximum torque under the specific gear and speed conditions and the exhaust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com