Lifting and transporting mechanism for cutting cool of vehicle roof water jet room

A technology of handling mechanism and canopy, applied in the direction of spring mechanism, hoisting device, etc., can solve the problems of high manufacturing cost, damaged profile of the fixture, low production efficiency, etc., to reduce the labor intensity of workers and ensure smooth switching. performance, and the effect of saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with specific drawings and embodiments.

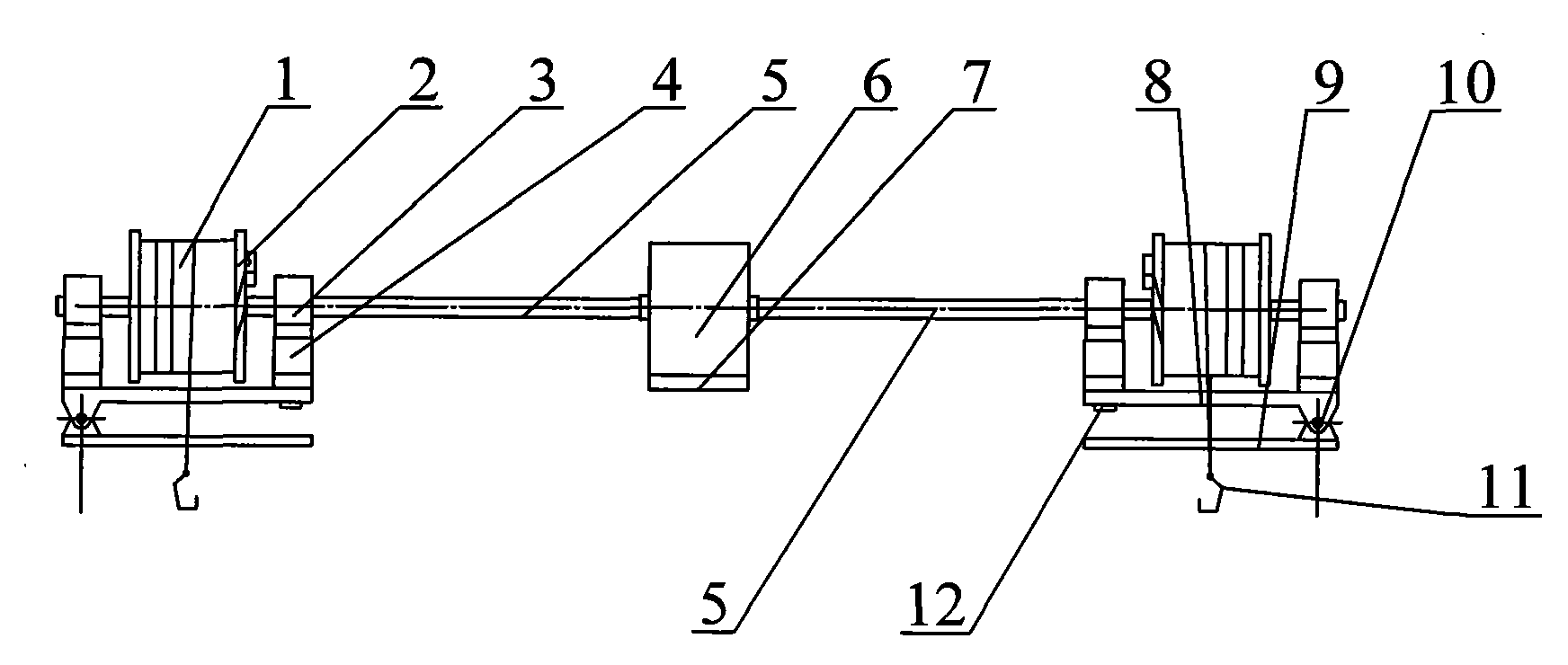

[0009] As shown in the figure: the cutting jig lifting and transporting mechanism includes traction drum 1, traction drum cover plate 2, support bearing 3, support bearing seat 4, transmission shaft 5, reduction motor 6, motor support plate 7, frame 8, swing limiter Position plate 9, limit plate bearing pin 10, steel wire hook 11, proximity switch 12 etc.

[0010] In the present invention, two transmission shafts 5 are respectively arranged on both sides of the reduction motor 6, and the other ends of the transmission shafts 5 are respectively connected to the traction drum 1 through the support bearing 3, and the traction drum 1 is provided with a steel wire rope, and the end of the steel wire rope is connected to a steel wire hook 11. The traction drum 1 is fixed on the frame 8, and the bottom of the frame 8 is provided with a limit plate 9, and the limit pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com