Digital sample printing method of spot color participation image

A digital proofing and spot color technology, which is applied in printing, rotary printing presses, printing machines, etc., can solve the problem that spot color hanging screen color simulation cannot be satisfied, digital proofing cannot realize WYSIWYG, and spot color digital proofing results cannot be achieved. Trust and other issues, to achieve the effect of high cost, long cycle, and reduce rework rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] The steps of this embodiment are as follows:

[0030] 1) Prepare the GMG spot color ladder version:

[0031] 11) Prepare spot color ladder file before printing: It is recommended to use the built-in ladder file of GMG software, which can realize automatic measurement. Such as figure 1 ;

[0032] 12) Engraving spot-color ladder ruler: use the commonly used spot-color electric engraving process to engrave the ladder ruler (such as genuine, pearlescent film reverse version, aluminum foil reverse version three electric engraving processes for engraving), different processes can be engraved on a plate roller on, convenient for proofing;

[0033] 13) The engraved version rollers are stored in the concave sample workshop for standby, pay attention to the protection of the version rollers.

[0034] 2) Correct the difference between GMG's built-in Pantone spot color library and concave samples:

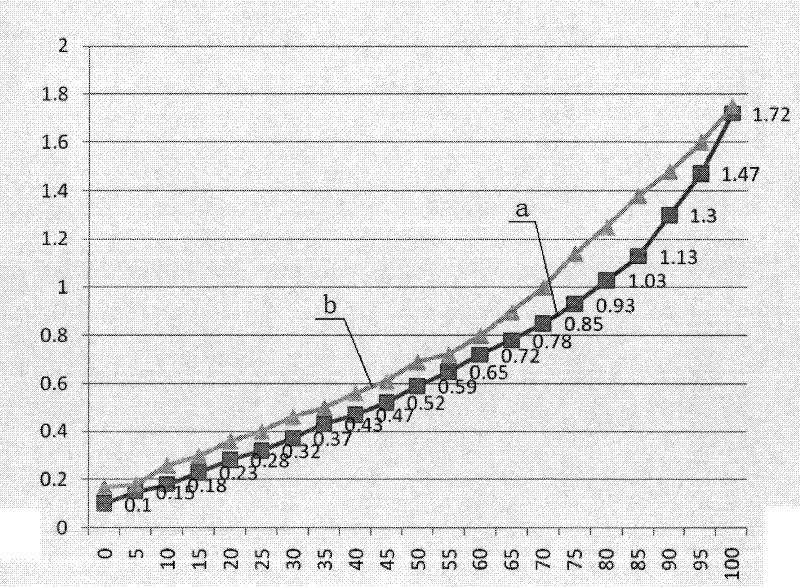

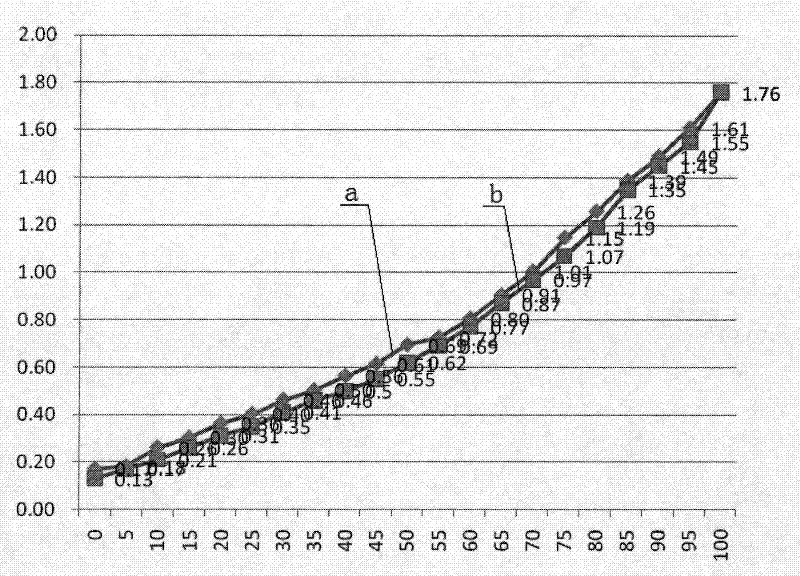

[0035] 21) Use the built-in Pantone spot color library to print spot color lad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com