Disc stepping motor

A stepping motor, disc type technology, applied in electrical components, electromechanical devices, etc., can solve the problems of low mechanical strength, complex overall structure, shortened axial dimension, etc., achieve high mechanical strength, simplify the overall structure, and improve excitation. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

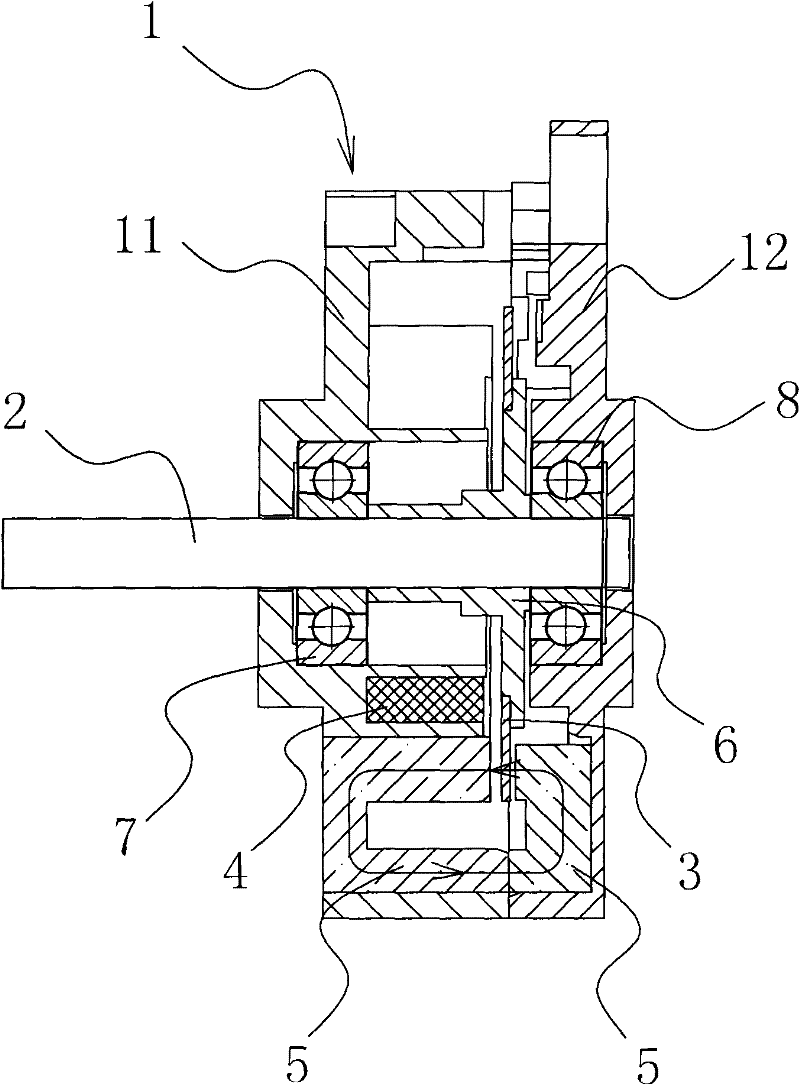

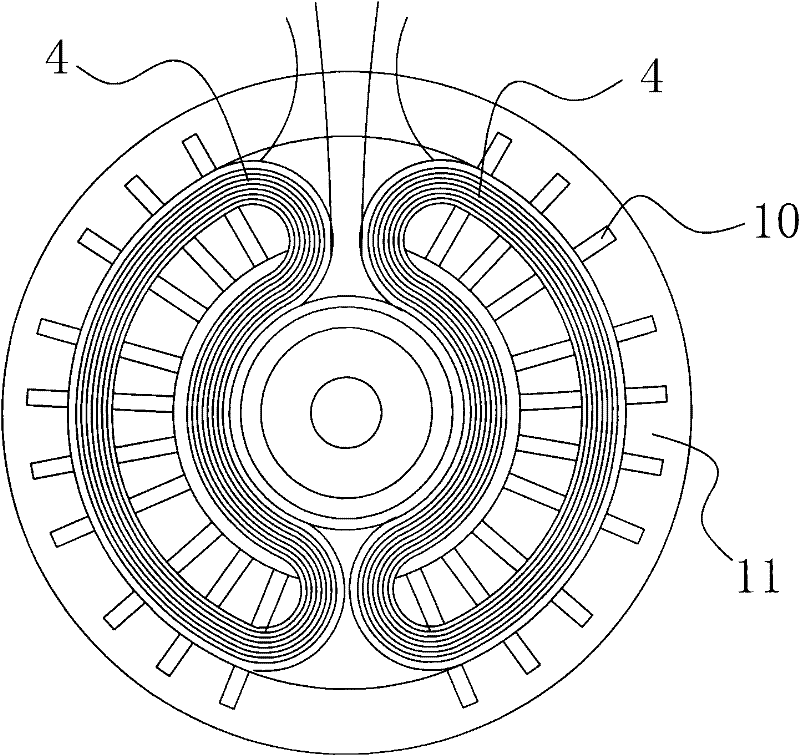

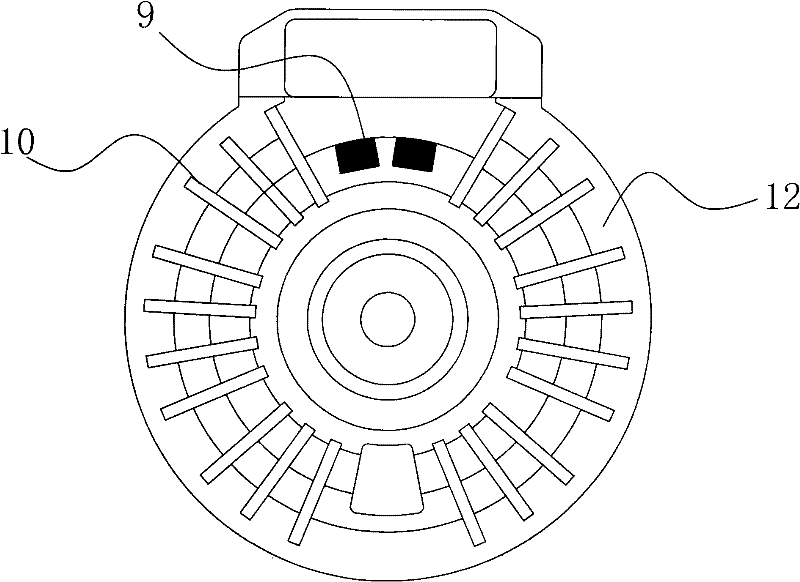

[0022] Such as Figure 1-4 As shown, the disc stepping motor includes a disc-shaped motor housing 1 formed by fastening and fixing a front end cover 11 and a rear end cover 12 . The motor shaft 2 passes through the motor housing 1 and can rotate relative to the motor housing 1 . A multi-pole magnetized annular disk 3 located in the motor housing 1 is fastened to the motor shaft 2 . The number of magnetic poles here is an even number. A winding 4 next to the annular disk 3 is fixed inside the motor housing 1 , and iron cores 5 are respectively fixed on both sides of the annular disk 3 .

[0023] More specifically, a positioning disc 6 is fixed on the motor shaft 2 , and the annular disk 3 is fixed on the positioning disc 6 . The windings 4 are fixed on the front end cover 11 , the number of the windings 4 is two groups and arranged symmetrically, and the front end cover 11 has a winding accommodation structure for fixing the windings 4 . The winding 4 has a ring-shaped wais...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com