110kv Composite Insulator Implanted with Fiber Bragg Grating

A technology of composite insulators and optical fiber gratings, applied to insulators, measuring the change force of optical properties of materials when they are stressed, and thermometers with physical/chemical changes, etc., can solve the risk of boarding poles, time-consuming, and work intensity Large, labor-intensive and other problems, to save manpower, prevent string drop, reduce the effect of string drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

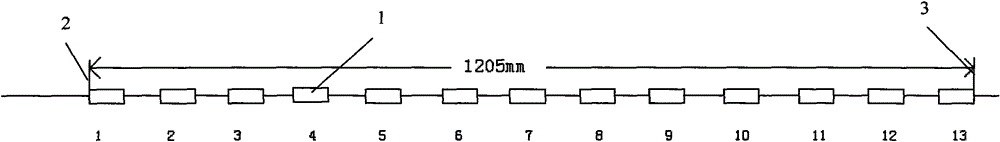

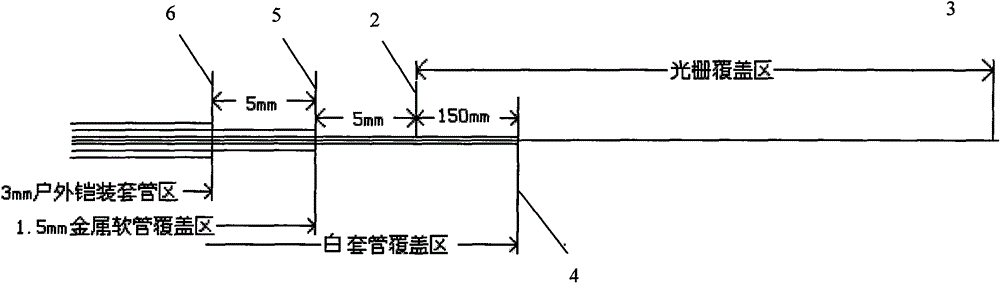

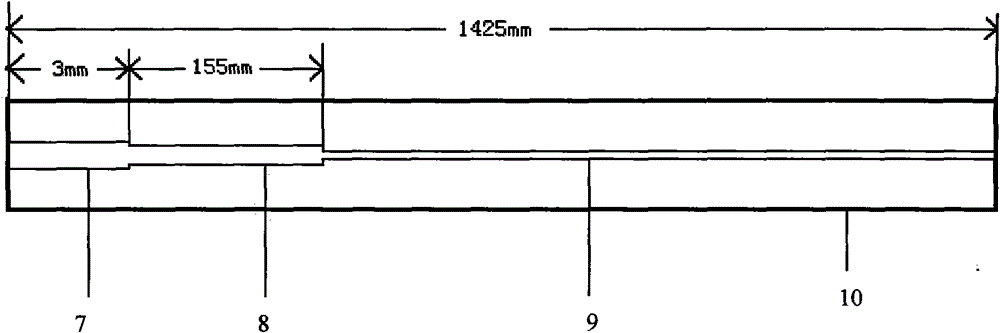

[0038] Such as Figure 1 to Figure 4 As shown, the 110kV composite insulator implanted with a fiber grating according to the present invention includes an optical fiber, a white sleeve, a soft metal sleeve, an outdoor armored sleeve and a core rod; the optical fiber is provided with a grating; There is a white sleeve, and a metal soft sleeve is sleeved on the outside of the white sleeve, and an outdoor armored sleeve is sleeved on the outside of the metal soft sleeve; the mandrel is engraved with grooves including groove 1, groove 2 and groove 3. Ladder groove; metal soft casing is fixedly connected in groove 1, and the termination cross section of the covered area of the metal soft casing coincides with the right end face of groove 1; the white casing is fixedly connected in groove 2, and the termination cross section of the coverage area of the white casing coincides with the right end surface of groove 2 The right end face of the fiber overlaps; the part of the optical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com