Optical lens assembly

A technology of optical lenses and components, applied in optical components, optics, instruments, etc., can solve problems such as the difficulty of effectively focusing light beams, and achieve the effects of smaller spherical aberration and astigmatism, improved imaging brightness, and reduced exit angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

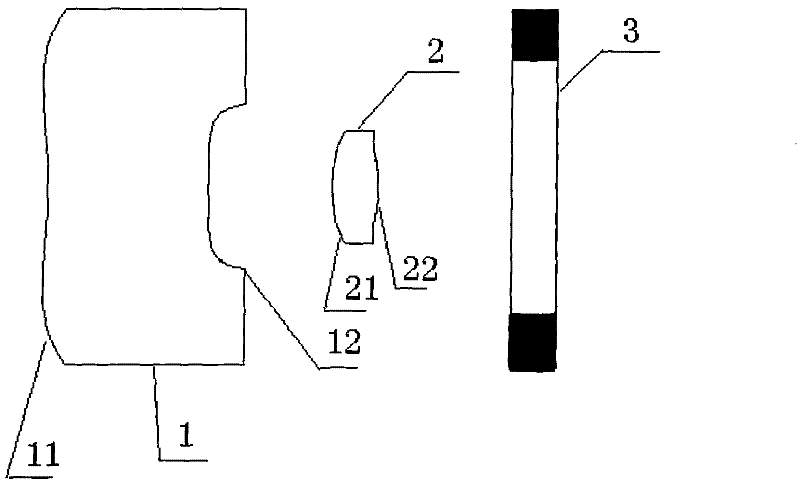

[0019] Such as figure 1 As shown, an optical lens assembly provided by an embodiment of the present invention includes a lens group and a fixed diaphragm 3. The lens group includes a first lens 1 and a second lens 2 coaxially and sequentially arranged from the object side to the image side The first lens 1 has a first surface 11 facing the object side and a second surface 12 facing the image side, and the second lens 2 has a third surface 21 facing the object side and a fourth surface 22 facing the image side; The first surface 11 and the second surface 12 are both aspherical; the first surface 11 is a convex surface, and the second surface 12 is a concave surface; the third surface 21 and the fourth surface 22 are both aspherical; the third surface 21 is a convex surface, and the fourth surface 22 is a convex surface; the first lens 1 has a negative refractive power as a whole, and the second lens 2 has a positive refractive power as a whole. The fixed diaphragm 3 is located o...

Embodiment 2

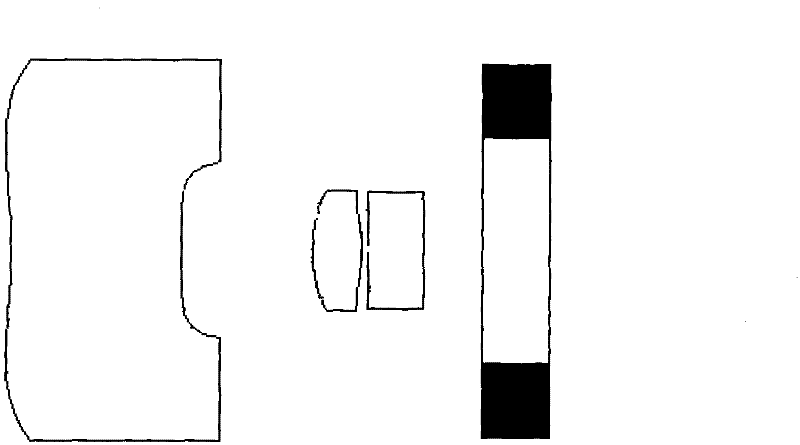

[0030] figure 2 It is a schematic diagram of the second embodiment of the optical lens assembly of the present invention, refer to figure 2 , The second embodiment of the present invention is proposed. This embodiment further proposes the following related parameters of the lens assembly based on the first embodiment:

[0031] Lens parameters:

[0032] Types of

Radius of curvature (R)

Quadric coefficient (k)

Thickness (dmm)

First surface

8.074533

-61.72694

2.80

Second surface

-5.721327

13.73578

2.05

Third surface

-9.945894

91.41678

0.9

Fourth surface

-1.92936

-2.27452

0.1

Front surface of filter

0.9

Back surface of filter

2.0

Image surface

0

[0033] Aspheric coefficient:

[0034] The first surface: (aspherical)

[0035] a 1 : -0.12711201

[0036] a 2 : 0.022288763

[0037] a 3 : -0.001871822

[0038] a 4 : 6.199145e-005

[0039] a 5 : 2.8747284e-005

[0040] a 6 : -5.9170367e-006

[0041] a 7 : 4.9221476e-007

[0042] a 8 : -1.5570923e-0...

Embodiment 3

[0076] Image 6 It is a schematic diagram of the second embodiment of the optical lens assembly of the present invention, refer to Image 6 , The second embodiment of the present invention is proposed. This embodiment further proposes the following related parameters of the lens assembly based on the first embodiment:

[0077] Lens parameters:

[0078] Types of

Radius of curvature (R)

Quadric coefficient (k)

Thickness (dmm)

First surface

9.226689

-78.91152

2.87

Second surface

-5.647945

13.8713

2

Third surface

-7.961955

33.04664

0.78

Fourth surface

-1.713565

-1.78347

0.1

Front surface of filter

0.9

Back surface of filter

2.1

Image surface

0

[0079] Aspheric coefficient:

[0080] The first surface (aspherical surface):

[0081] a 1 : -0.13239387

[0082] a 2 : 0.020306834

[0083] a 3 : -0.0012555407

[0084] a 4 :-4.8945981e-005

[0085] a 5 : 3.6343123e-005

[0086] a 6 : -5.6776908e-006

[0087] a 7 : 4.2806789e-007

[0088] a 8 : -1.2934...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com