High speed maglev train guiding and eddy current braking integrative electromagnet device

A technology for maglev trains and eddy current braking, which is applied in electric braking systems, asynchronous inductive clutches/brakes, vehicle components, etc. It can solve the problems of easy-to-damage vehicle structures, single functions, and concentrated braking force to achieve braking effects Prediction, Simplification of System Structure, Effect of Vehicle Structure Damage Suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

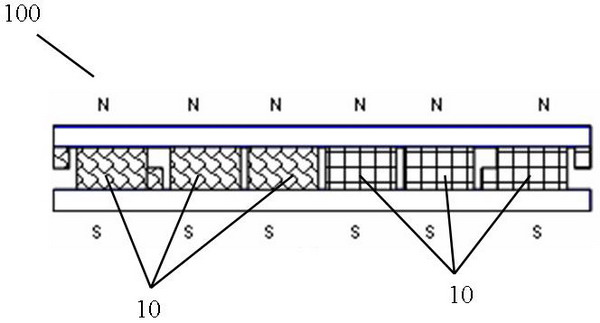

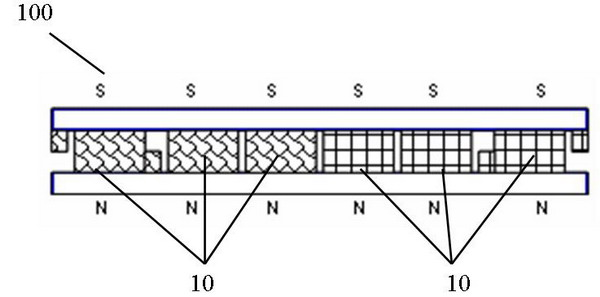

[0024] The electromagnet device integrating guidance and eddy current braking of a high-speed maglev train according to the present invention has six magnetic poles arranged along the forward direction of the train, so that the electromagnet has a U-shaped structure.

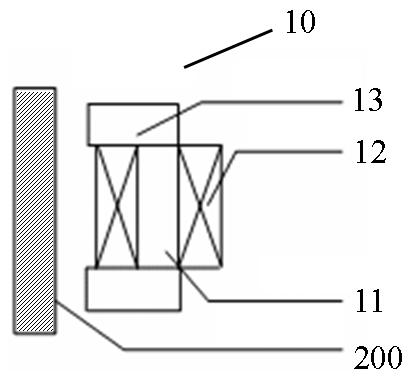

[0025] Such as figure 1 As shown, each magnetic pole 10 is a U-shaped structure in which the two pole surfaces are respectively parallel to the upper and lower surfaces of the guide rail surface 200, including an iron core 11, a coil 12 wound outside the iron core 11, and magnetic poles sandwiched at both ends of the iron core 11. The yoke 13 ; the iron core 11 and the yokes 13 at both ends constitute the U-shaped structure of the magnetic pole 10 . By changing the direction of the current applied to the coil 12, the polarity distribution on the magnetic pole 10 can be changed.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com