Clutch for electric control silicon-oil fan

A clutch and fan technology, applied in clutches, fluid clutches, machines/engines, etc., can solve the problems of central processor speed data errors, consumption of engine energy, and inability to receive, saving production and assembly costs and reducing the number of parts and components , the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

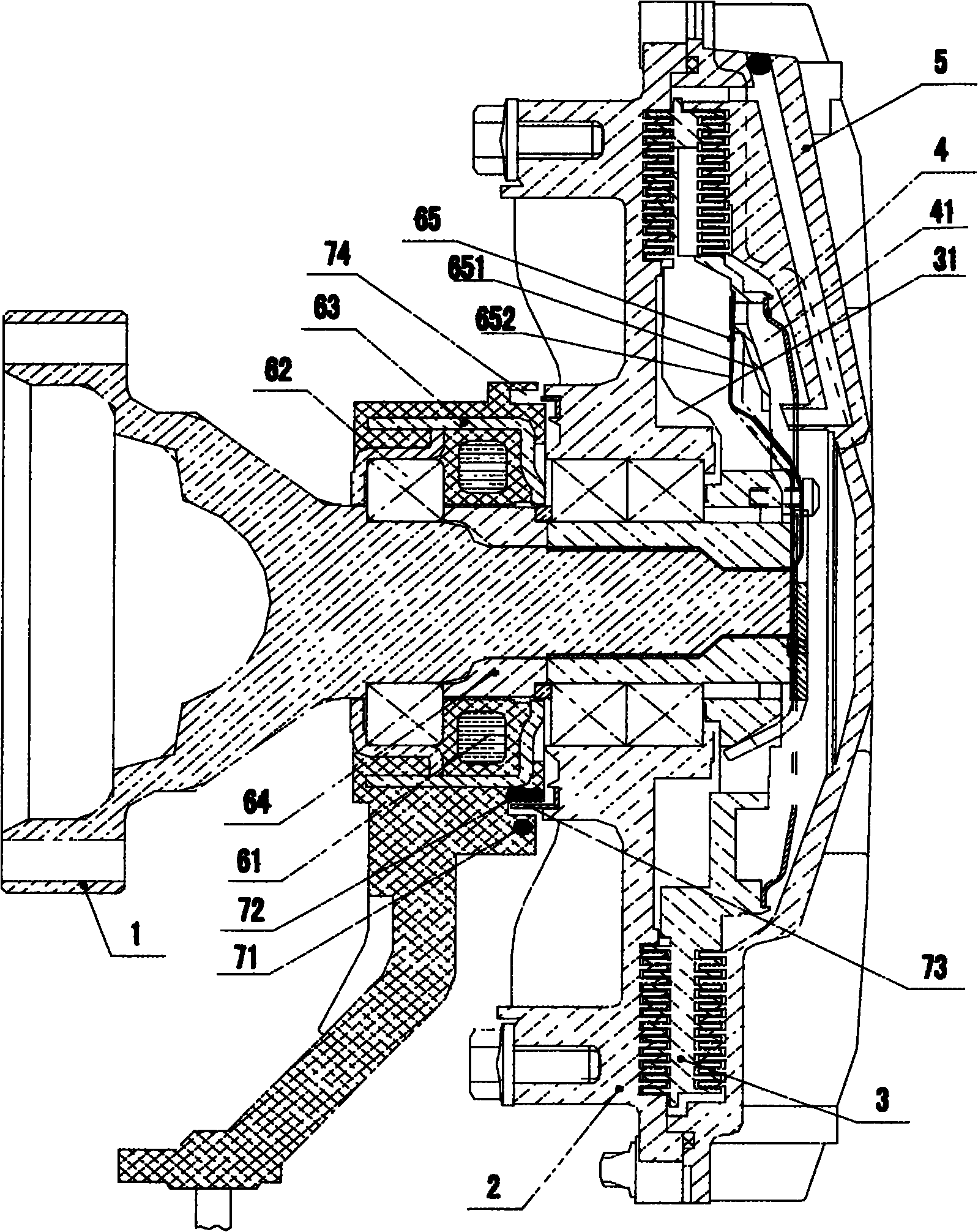

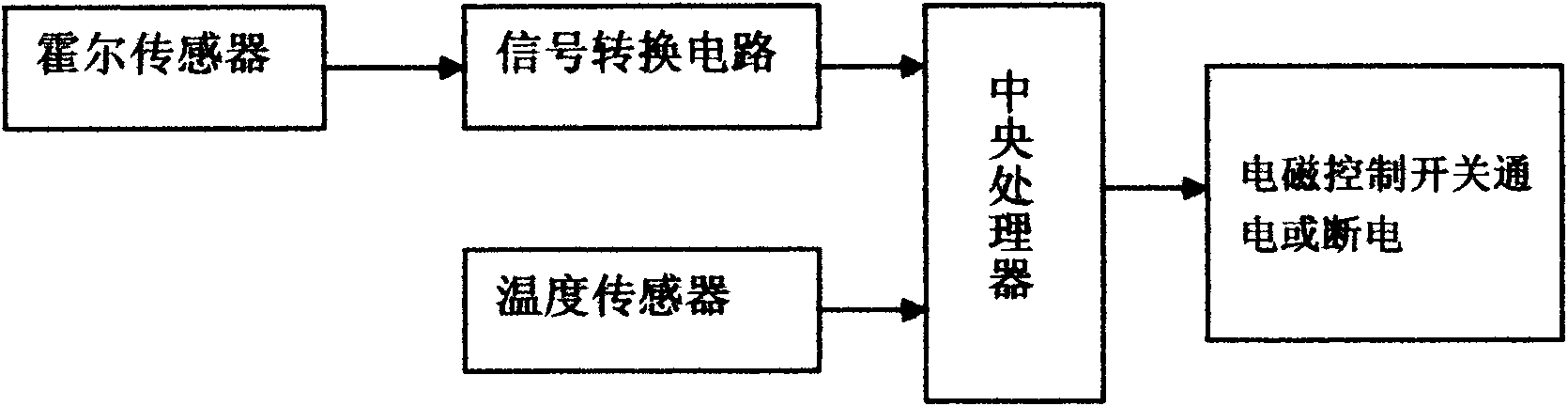

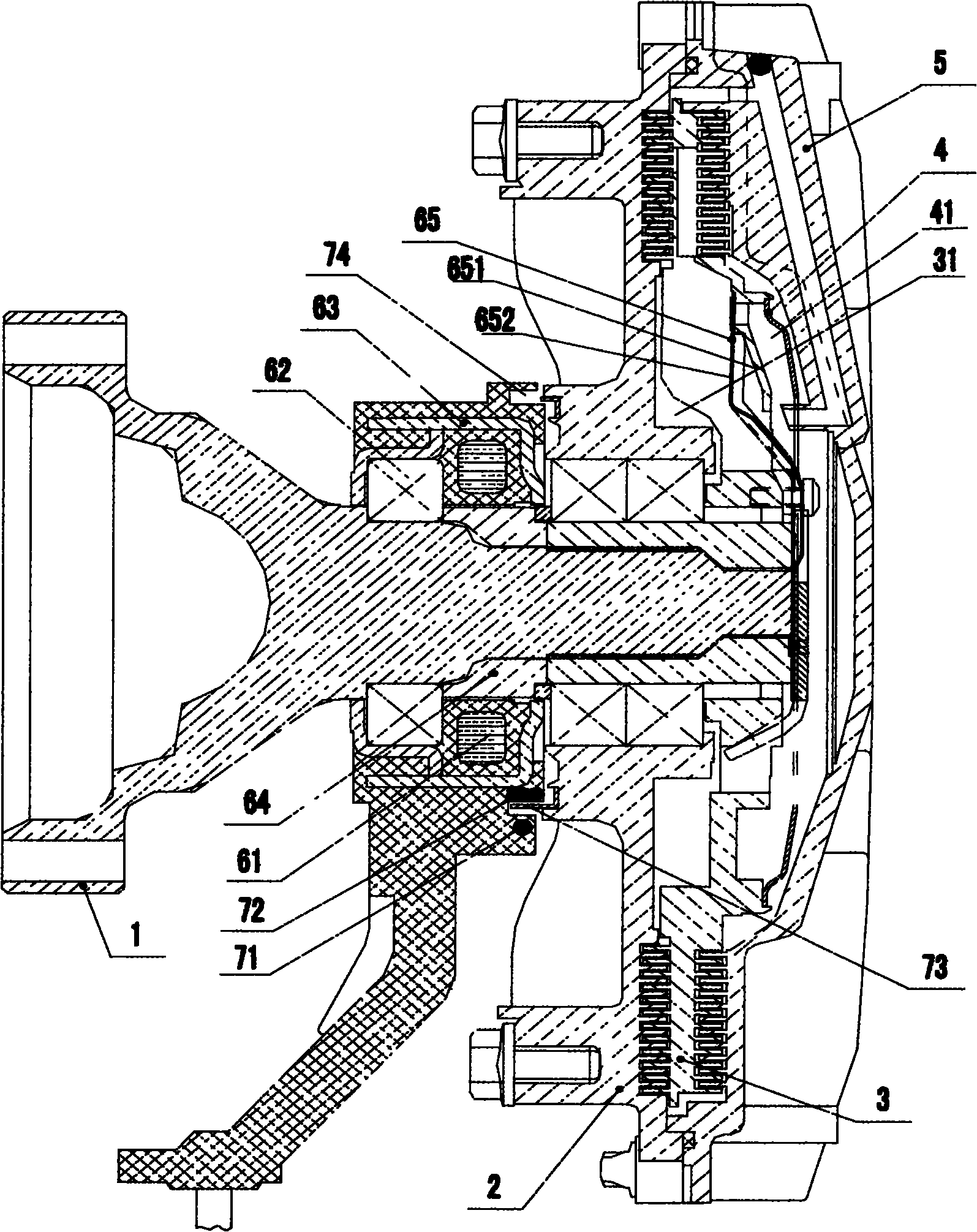

[0019] With regard to the present invention, a preferred embodiment is now described in conjunction with the drawings: an electronically controlled silicon oil fan clutch, which includes a driving shaft 1, a housing 2, a driving plate 3, a driven plate 4, an end cover 5, and an electromagnetic control switch , Fan speed test component, see figure 1 , figure 2 ,among them:

[0020] The driving shaft 1, which rotates synchronously with the engine shaft, the housing 2 is fixed on the driving shaft 1 through bearings; the driving shaft 1 is fixedly connected with the driving plate 3 that rotates with the driving shaft; the end cover 5 is located at the front end of the driving plate 3 , And the housing 2 is fixed as a whole by screws, the end cover 5 and the housing 2 are correspondingly provided with tooth grooves, and the front and rear tooth saws on the active plate 3 mesh with the tooth grooves on the end cover 5 and the housing 2 respectively; The driven plate 4 is located bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com