SiO2 nanoparticle composite cage compound thermoelectric material and preparation method thereof

A cage compound and nanoparticle technology, which is applied in the direction of thermoelectric device node lead wire materials, thermoelectric device manufacturing/processing, etc., can solve the problems of easy agglomeration and difficult dispersion of composite particles, so as to improve thermoelectric performance and simple preparation method Ease of operation and reduction in electrical transport performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Tetraethyl orthosilicate Si(OC 2 h 5 ) 4 Dissolve in absolute ethanol to configure tetraethyl orthosilicate alcohol solution with a volume percentage of 5%; mix absolute ethanol and distilled water to configure an ethanol solution with a concentration of 75%, and dissolve a 25% analytically pure ammonia solution with a concentration of In this ethanol solution, configure ammonia solution II with a volume percentage of 1%; after stirring for 30 minutes, use a peristaltic pump to slowly drop solution I into solution II at a rate of 1.25 ml / min to obtain a suspension; continue stirring the After 5 hours of suspension, it was sedimented for 10 hours, then centrifuged, followed by vacuum drying at 60°C for 5 hours, and then vacuum drying at 120°C for 5 hours to obtain SiO 2 Powder particles.

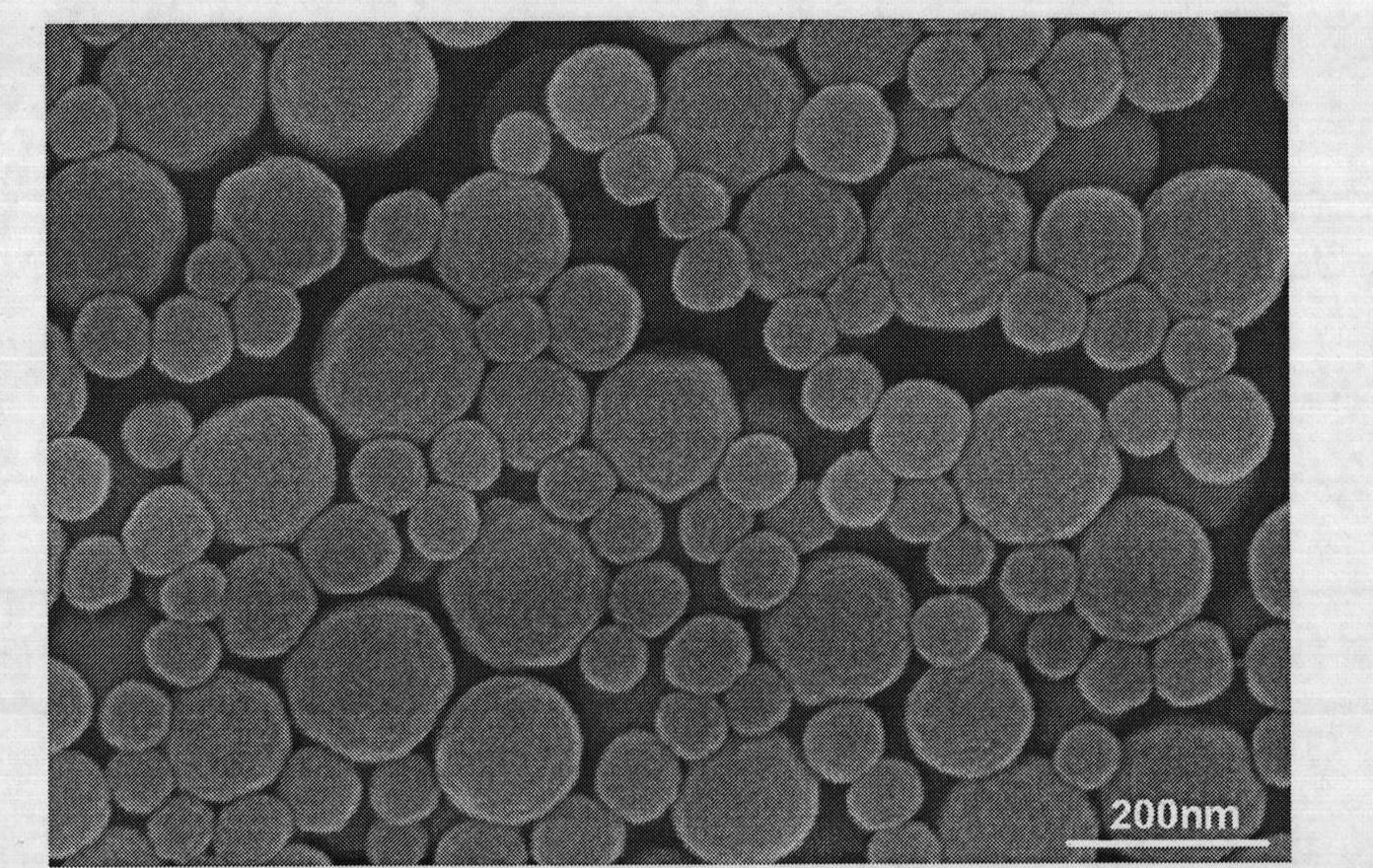

[0033] The SiO was observed using a SEM, field emission scanning electron microscope 2 Powder particles, obtained as figure 1 As shown in the SEM picture, it can be seen that the ...

Embodiment 2

[0038] 2.79ml tetraethyl orthosilicate Si(OC 2 h 5 ) 4 Dissolved in 22.2ml of absolute ethanol, the configuration volume percentage is 11.1% tetraethyl orthosilicate alcohol solution 1; the concentration is 25% analytical pure ammonia solution mixed with 6.8ml water and 17.6ml of absolute ethanol, the configuration volume percentage is 2.5% ammonia solution II; after stirring for 30 minutes respectively, use a peristaltic pump to slowly drop solution I into solution II at a rate of 1.25 ml / min to obtain a suspension; continue to stir the suspension for 5 hours and settle it 10 h, followed by centrifugation, followed by vacuum drying at 60 °C for 5 h, followed by vacuum drying at 120 °C for 5 h to obtain SiO 2 Powder particles.

[0039] Observe the SiO using SEM 2 powder particles, to obtain similar figure 1 The SEM picture shown, indicates that the SiO 2 The particle size of the powder particles is nanoscale, specifically 50nm-200nm.

[0040] Weigh 3 grams of type I cag...

Embodiment 3

[0043] Tetraethyl orthosilicate Si(OC 2 h 5 ) 4 Dissolve in absolute ethanol to configure tetraethyl orthosilicate alcohol solution 1 with a volume percentage of 5%; mix absolute ethanol and distilled water to configure an ethanol solution with a concentration of 80%, and dissolve a 25% analytically pure ammonia solution with a concentration of Configure volume percent in this ethanol solution and be 5% ammonia solution two, take 4g Ba simultaneously 8 Ga 16 Ge 30 Put the powder in 25ml solution 2; after stirring for 30 minutes, use a peristaltic pump to slowly drop 3ml solution 1 into solution 2 at a rate of 1.0 ml / min to obtain SiO 2 The clathrate compound suspension composed of particles; continue to stir the suspension for 5 hours, then settle it for 10 hours, then centrifuge, and then dry it in vacuum at 60°C for 5 hours to obtain SiO 2 Particle Composite Ba 8 Ga 16 Ge 30 Powder: The target powder is subjected to hot-press sintering. The specific hot-press sinteri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com