Bottle separation device

A sorting device and bottle technology, applied in sorting and other directions, can solve problems such as working speed limitation, high system cost, unstable detection quality, etc., and achieve the effect of reducing cost, ensuring detection quality, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

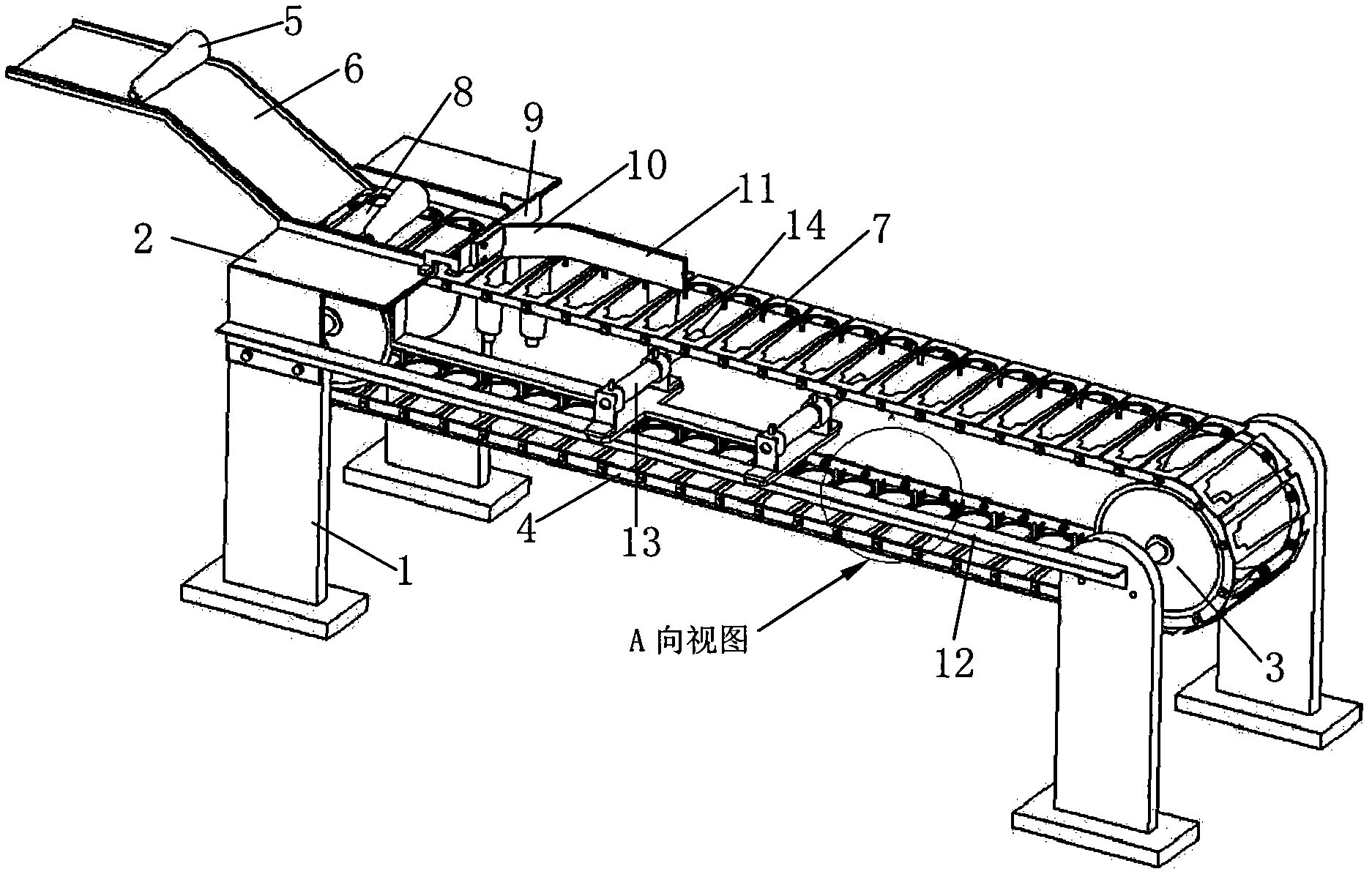

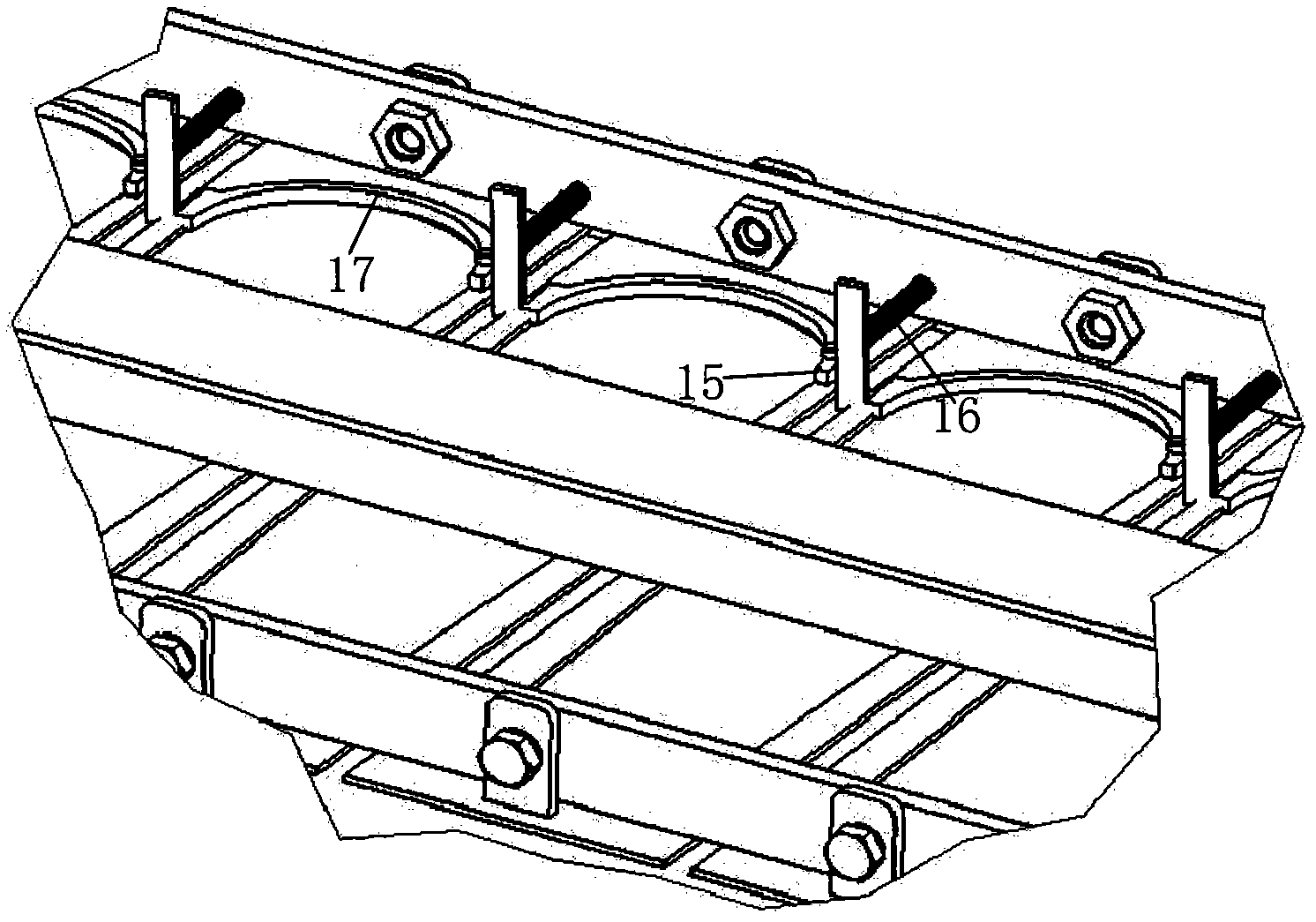

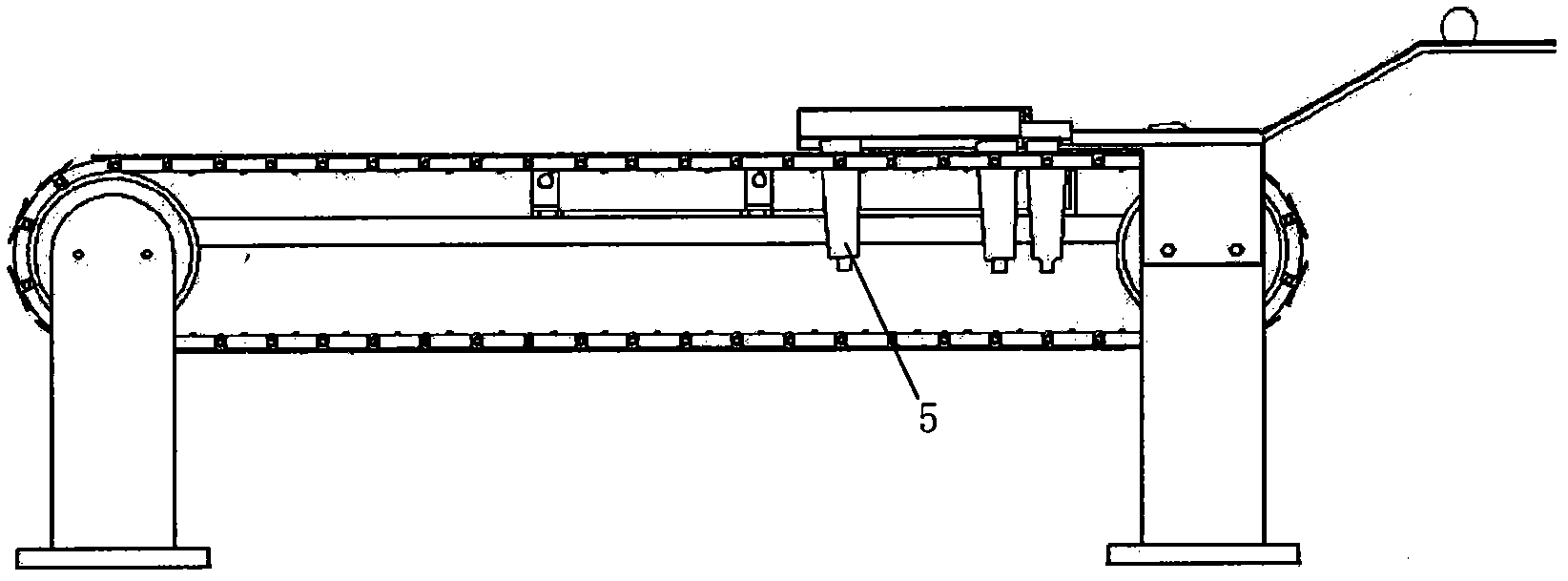

[0013] The bottle to be detected (5) falls onto the conveyor belt of the sorting system through the guide groove (6) installed on the frame II (2) by bolts, and the frame II (2) is installed on the frame I (1) by bolts . The transmission device includes a sprocket (3), a chain (4) and a conveyor belt mother plate (7). The sprocket (3) is installed on the frame I (1) through the rotating shaft, and the conveyor belt is composed of a rectangular conveyor belt motherboard (7) mounted on the chain through hinges. Each motherboard has grooves similar to the projection of the bottle shape. The length of the groove is slightly shorter than the height of the bottle body. The bottle moves forward with the conveyor belt under the support of the pallet (8) which is bolted to the frame II (2) under the conveyor belt, and passes through the guide plate I ( 9) After that, the bottle will be located in the groove of the conveyor belt motherboard in a horizontal manner. When the bottle move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com