Mechanical pencil

A mechanical pencil and action technology, applied in mechanical pencils, printing, writing utensils, etc., can solve the problems of poor pen feel, damage to paper surface, scratching paper, etc., to prevent writing efficiency, prevent core breakage, and solve large changes in concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

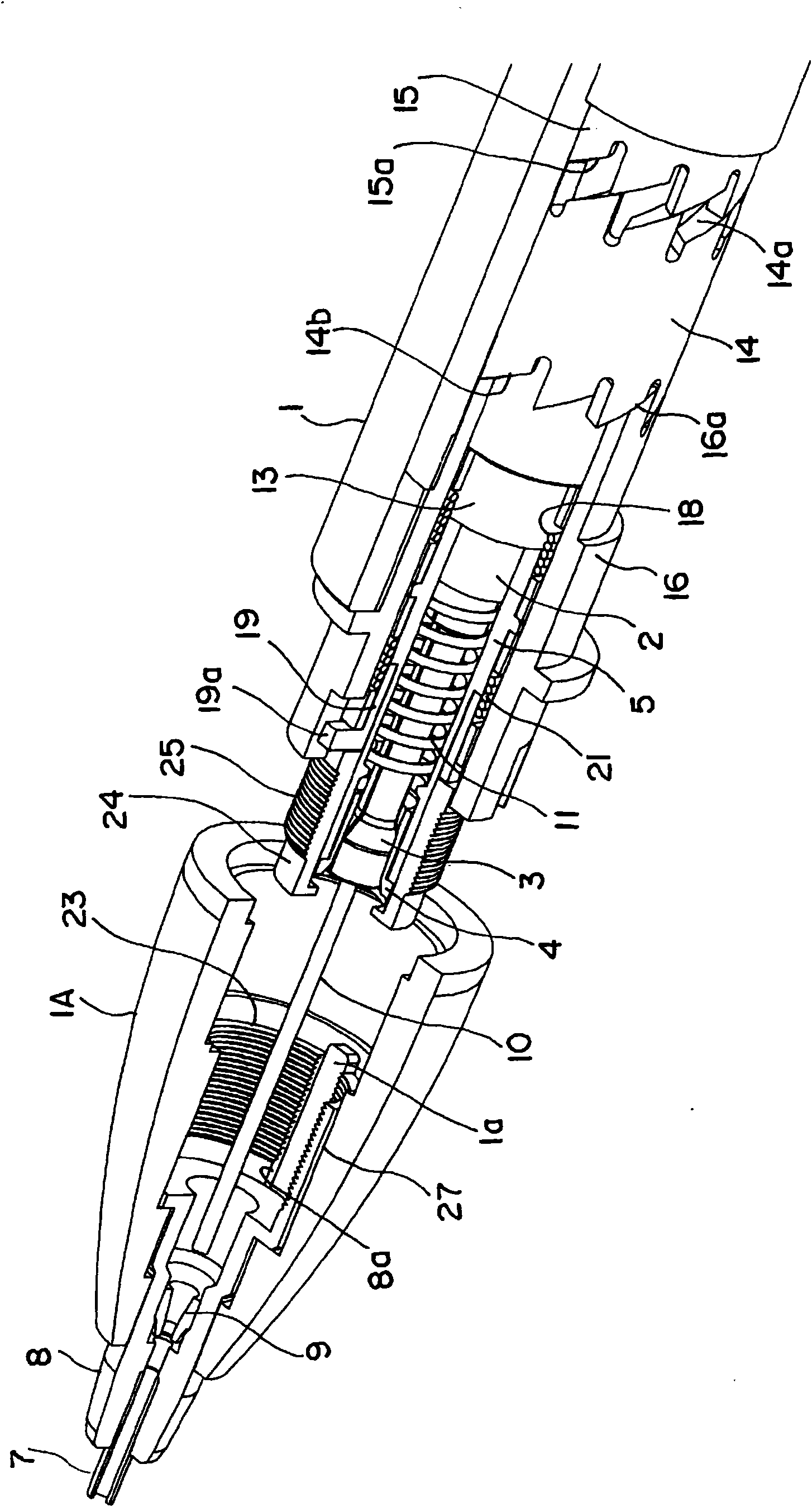

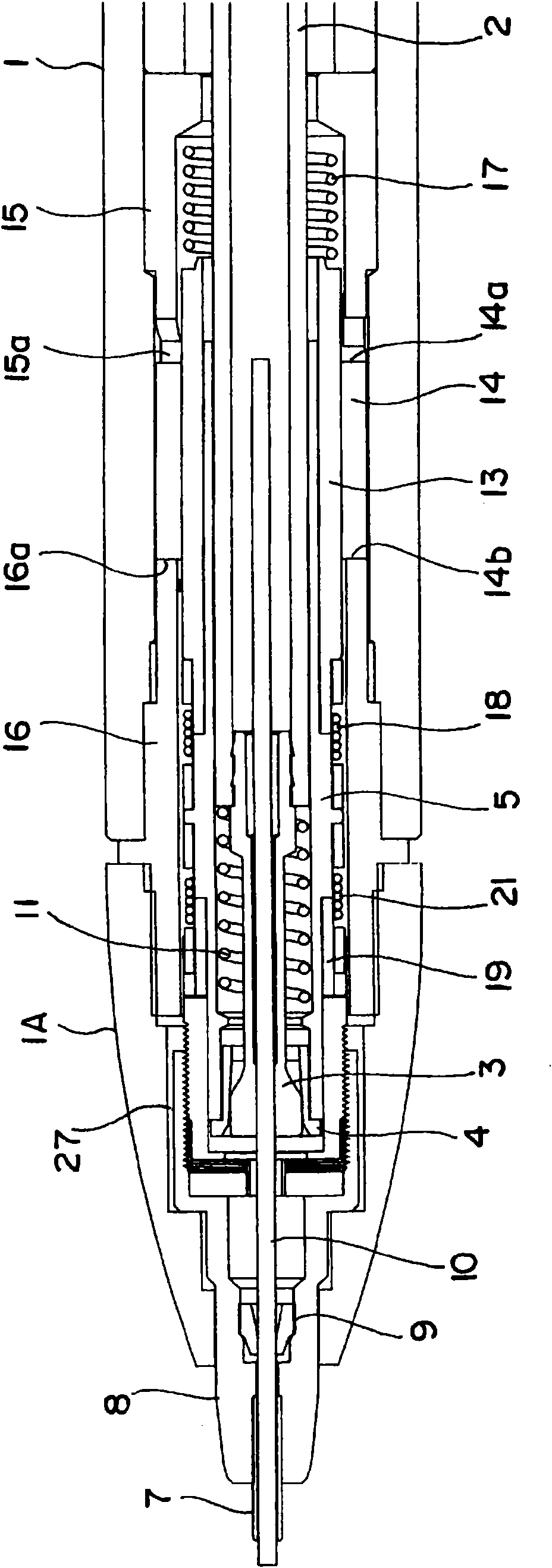

[0068] Hereinafter, the mechanical pencil of the present invention will be described based on the illustrated embodiment. Figure 1 ~ Figure 3 Shows the first embodiment of the mechanical pencil of the present invention, figure 1 It shows the front half of the mechanical pencil, and shows a perspective view in a state where the tip of the mouth is separated from the shaft barrel and a part is cut away. In addition, figure 2 Is a cross-sectional view of the front half showing a state cut along its axial direction, image 3 For being with figure 2 The state shown is a cross-sectional view of a state cut through a plane orthogonal to 90 degrees.

[0069] In addition, in the following, the structure of each part denoting the same part with the same symbol is described separately by the reference symbol, but in each figure described below, a part of the symbol is appropriately omitted according to the figure.

[0070] The symbol 1 denotes a shaft barrel constituting its outline. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com